Multi-cascade thermoelectric device and manufacturing method thereof

A thermoelectric device, multi-cascading technology, applied in the direction of thermoelectric device, thermoelectric device manufacturing/processing, electrical components, etc., can solve the problems of high cost, low economic efficiency, low yield rate, etc., to avoid the influence of temperature distribution, The effect of improving the difficulty of the process and reducing the production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

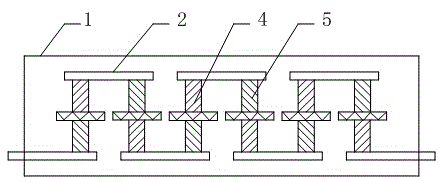

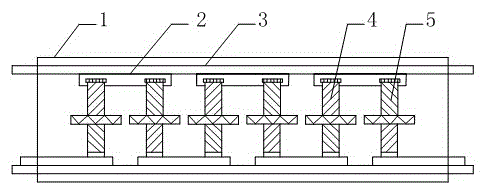

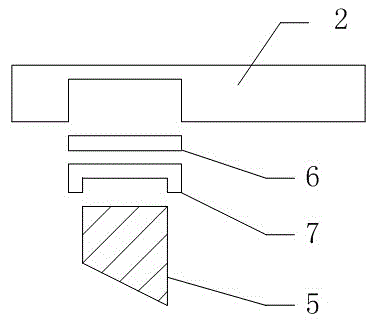

[0036] The invention discloses a multi-cascade thermoelectric device. It includes a packaging case 1 and a power generation unit arranged inside the packaging case 1 , the upper and lower ends of the power generation unit are provided with conductive wiring 2 and a ceramic substrate 3 for mechanically pressing the power generation unit. Since the multi-cascade thermoelectric device of the present invention needs to be used at high temperature, in order to prevent the oxidation of thermoelectric materials and electrode materials, and to avoid the air convection and heat conduction inside the packaging sleeve 1, resulting in bypass heat loss, the device needs to be vacuum-packaged. In order to achieve this purpose, the packaging cover 1 should be selected from oxidation-resistant, high-ductility metal materials such as nickel-chromium-based alloys, so as to completely hermetically seal the entire thermoelectric module.

[0037] Such as Figure 2~3 As shown, the power generation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com