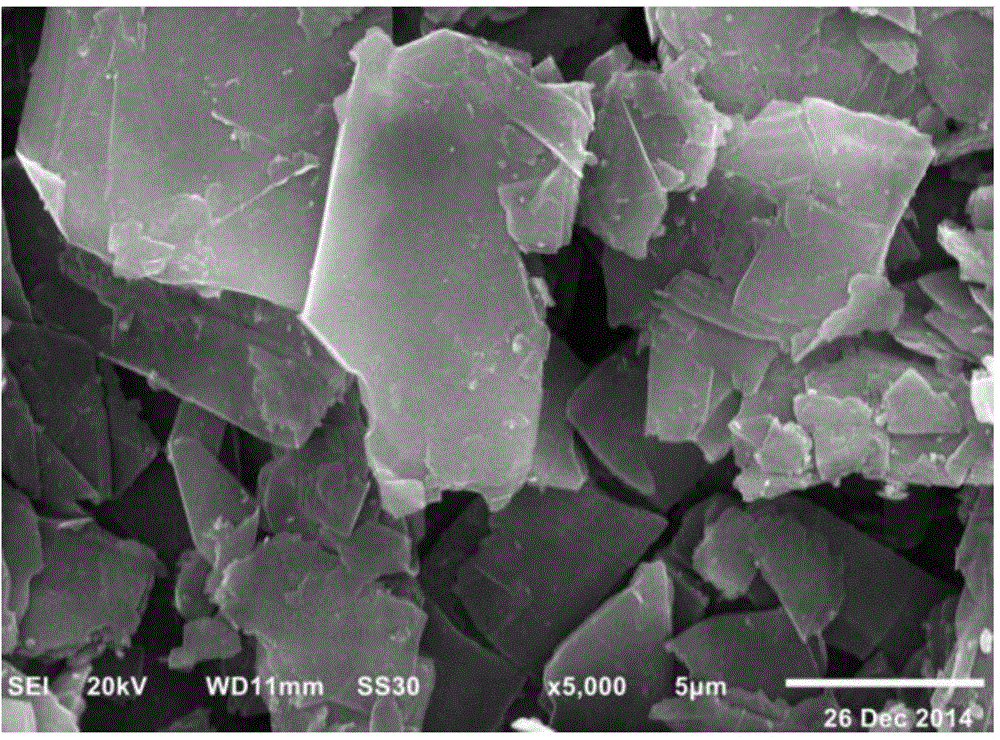

Preparation method of fumed silica and nanoscale carbon black composite material

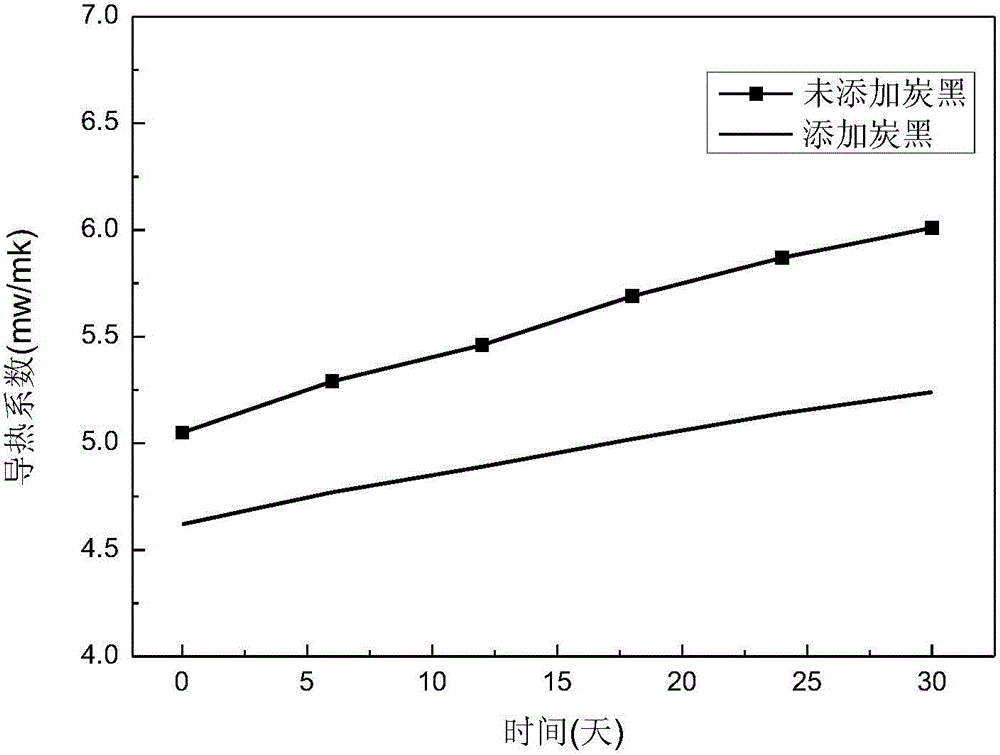

A technology of fumed silica and composite materials, applied in the direction of silica, silicon oxide, etc., can solve the problems of unsuitability for practical application and high thermal conductivity, achieve good application value, reduce radiation heat transfer, and improve thermal insulation performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

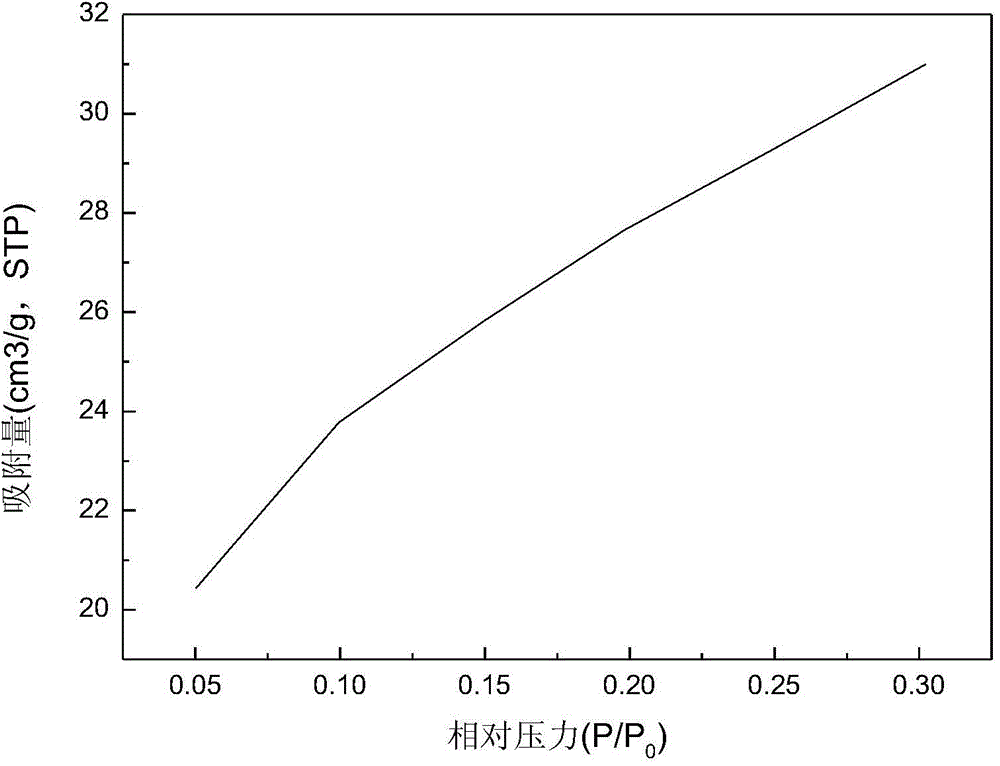

Method used

Image

Examples

Embodiment 1

[0029] Weigh 80g of fumed silica in a closed mixer, turn on the mixer, and set the stirring speed to 150rpm, weigh 15g of polyester chopped strands with a diameter of 9μm and a length of 9mm in the mixer, and stir for 10min. until the two are evenly mixed. Continue to add 2g of opacifying agent, adjust the stirring speed to 300rpm, and continue to stir for 30min to form a uniform nanocomposite material. The composite material is loaded into a pre-cut non-woven bag of a certain size, flattened, pressed, and finally dried and vacuumed to form a vacuum insulation panel.

Embodiment 2

[0031] Weigh 80g of fumed silica in a closed mixer, turn on the mixer, and set the stirring speed to 150rpm, weigh 15g of polyester chopped strands with a diameter of 9μm and a length of 9mm in the mixer, and stir for 10min. until the two are evenly mixed. Continue to add 2g of opacifying agent and 1g of nano-carbon black, adjust the stirring speed to 300rpm, and continue to stir for 30min to form a uniform nanocomposite material. The composite material is loaded into a pre-cut non-woven bag of a certain size, flattened, pressed, and finally dried and vacuumed to form a vacuum insulation panel.

Embodiment 3

[0033] Weigh 80g of fumed silica in a closed mixer, turn on the mixer, and set the stirring speed to 150rpm, weigh 15g of polyester chopped strands with a diameter of 9μm and a length of 9mm in the mixer, and stir for 10min. until the two are evenly mixed. Continue to add 2g of opacifying agent and 3g of nano-carbon black, adjust the stirring speed to 300rpm, and continue to stir for 30min to form a uniform nanocomposite material. The composite material is loaded into a pre-cut non-woven bag of a certain size, flattened, pressed, and finally dried and vacuumed to form a vacuum insulation panel.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com