Powder removal prevention aerogel composite insulation felt and preparation method thereof

A composite thermal insulation and aerogel technology, applied in chemical instruments and methods, synthetic fibers, ceramic products, etc., can solve the problems of high equipment cost, long process, large aerogel content, etc., and improve the thermal insulation ability. , the effect of reducing radiation heat transfer and reducing heat conduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~8

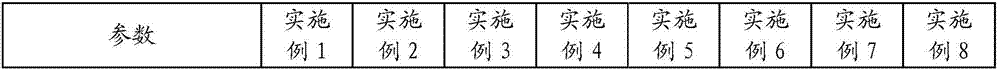

[0083] 1. A formula of anti-powdering airgel composite insulation felt, comprising airgel wet gel solution, fiber skeleton material, the weight ratio of airgel wet gel solution and fiber skeleton material is 2~30:1;

[0084] The airgel wet gel solution includes an airgel precursor and a binder, and the amount of the binder added is 0.1 to 5% of the solid content of the airgel precursor;

[0085] The solid content of the airgel precursor is 5-35%, which means that the airgel solid content in the airgel precursor is 5-35%;

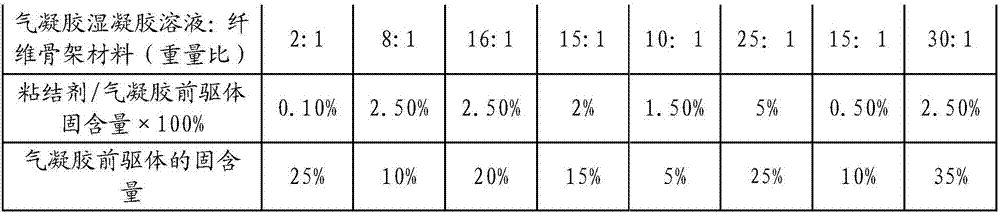

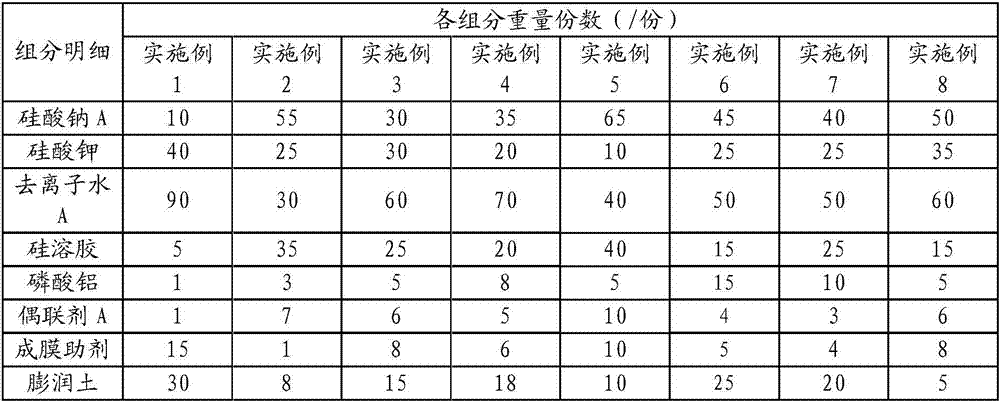

[0086] The binder, in parts by weight, includes 10-65 parts by weight of sodium silicate A, 10-40 parts by weight of potassium silicate, 30-90 parts by weight of deionized water A, and 5-40 parts by weight of silicon Sol, 1-15 parts by weight of aluminum phosphate, 1-10 parts by weight of coupling agent A, 1-15 parts by weight of film-forming aid, and 5-30 parts by weight of bentonite;

[0087] The consumption details of each component among the embodiments...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com