Vitrified micro-bead heat preserving and insulating material and method of preparing same

A thermal insulation, vitrified microbead technology, applied in sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problem of anti-seepage and anti-cracking flexible mortar that does not yet have a vitrified microbead thermal insulation layer cover The problems such as thermal insulation materials of the cover layer can achieve the effects of good thermal insulation effect, poor workability and low thermal conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

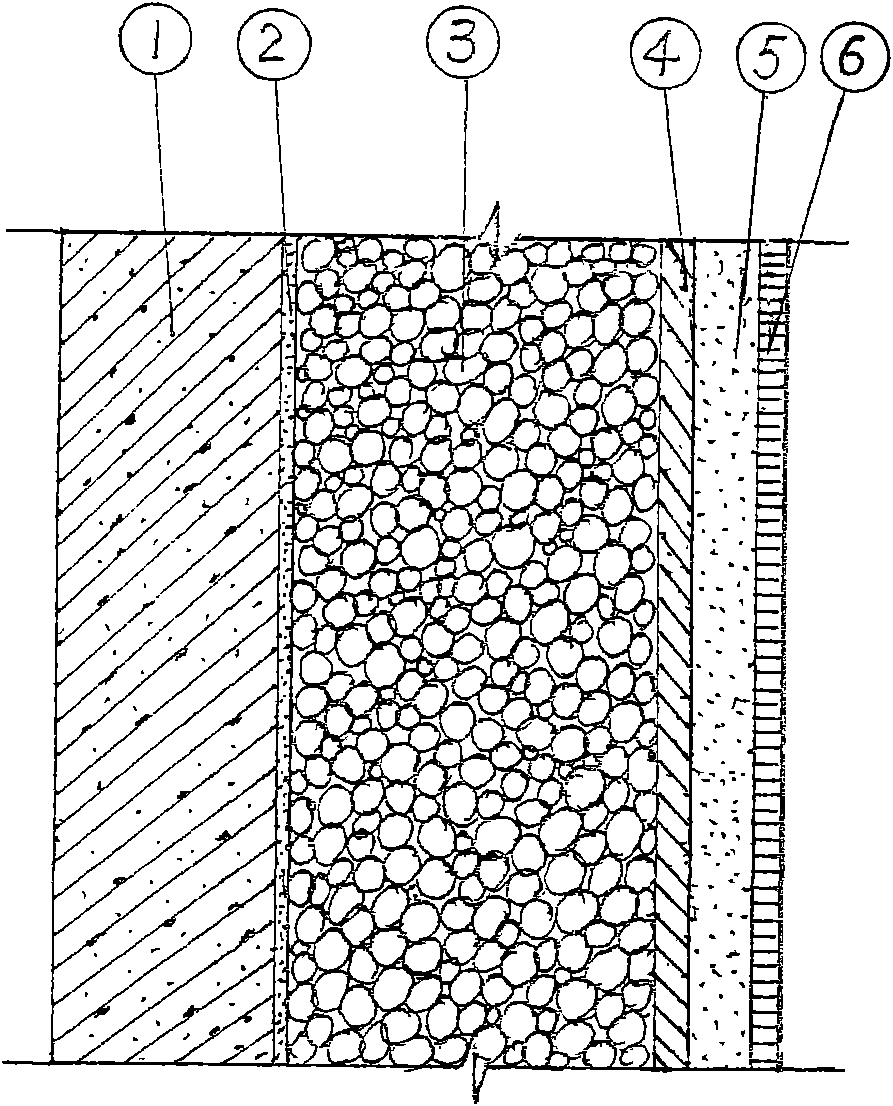

Image

Examples

Embodiment 1

[0018] 1. Preparation of vitrified microbead thermal insulation dry powder:

[0019] Vitrified microbead thermal insulation dry powder includes the following raw materials by weight: special cement 39, fly ash 2, masterbatch 9, vitrified microbead 50, and the four components are mixed according to the proportion; the masterbatch includes the following Raw materials by weight: 1.6 redispersible latex powder, 4 heavy calcium carbonate, 0.45 methyl cellulose ether, 1.25 wood fiber, 0.2 water repellent, 1.5 air-entraining agent, and 0.3 thixotropic lubricant.

[0020] 2. Preparation of anti-seepage and anti-crack flexible mortar:

[0021] The anti-seepage and anti-crack flexible mortar includes the following raw materials by weight: ordinary silicon cement 39, fly ash 4, polymer 8, quartz sand 49, and the four components are mixed according to the proportion; the polymer includes the following weight components Raw materials: heavy calcium carbonate 2, methyl cellulose ether 0.8,...

Embodiment 2

[0042] 1. Vitrified microbead thermal insulation dry powder includes the following raw materials by weight: special cement 48, fly ash 5, masterbatch 7, vitrified microbead 40, and the four components are mixed according to the proportion, and the masterbatch Raw materials comprising the following weight components: 1.0 redispersible latex powder, 5 heavy calcium carbonate, 0.2 methyl cellulose ether, 0.3 wood fiber, and 0.5 thixotropic lubricant.

[0043]2. The anti-seepage and anti-crack flexible mortar includes the following raw materials by weight: ordinary silicon cement 32, fly ash 6, polymer 10, quartz sand 52, and the four components are mixed according to the proportion, and the polymer includes the following weight Component raw materials: heavy calcium carbonate 5, methyl cellulose ether 0.5, latex powder 2, starch ether 0.10, polypropylene fiber 0.1, wood fiber 0.3, osmotic crystalline waterproofing agent 2.

[0044] The slurry preparation method of Embodiment 2, c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com