Heat recovering device

A heat recovery device and heat technology, applied in indirect heat exchangers, heat exchanger types, lighting and heating equipment, etc., can solve the problem of lowering the internal temperature of the firing furnace, reduce thermal insulation materials, and improve heat recovery efficiency. , the effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

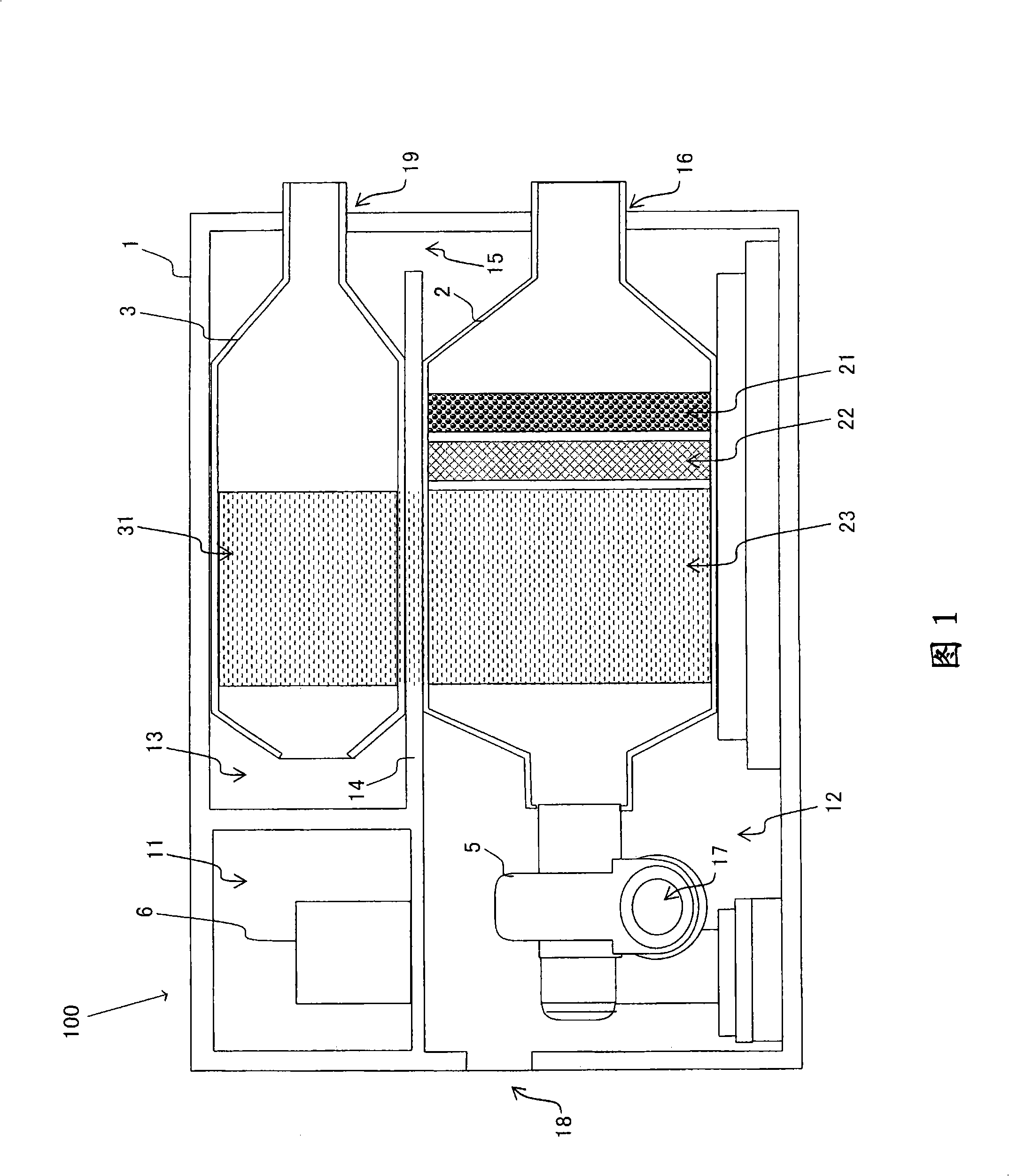

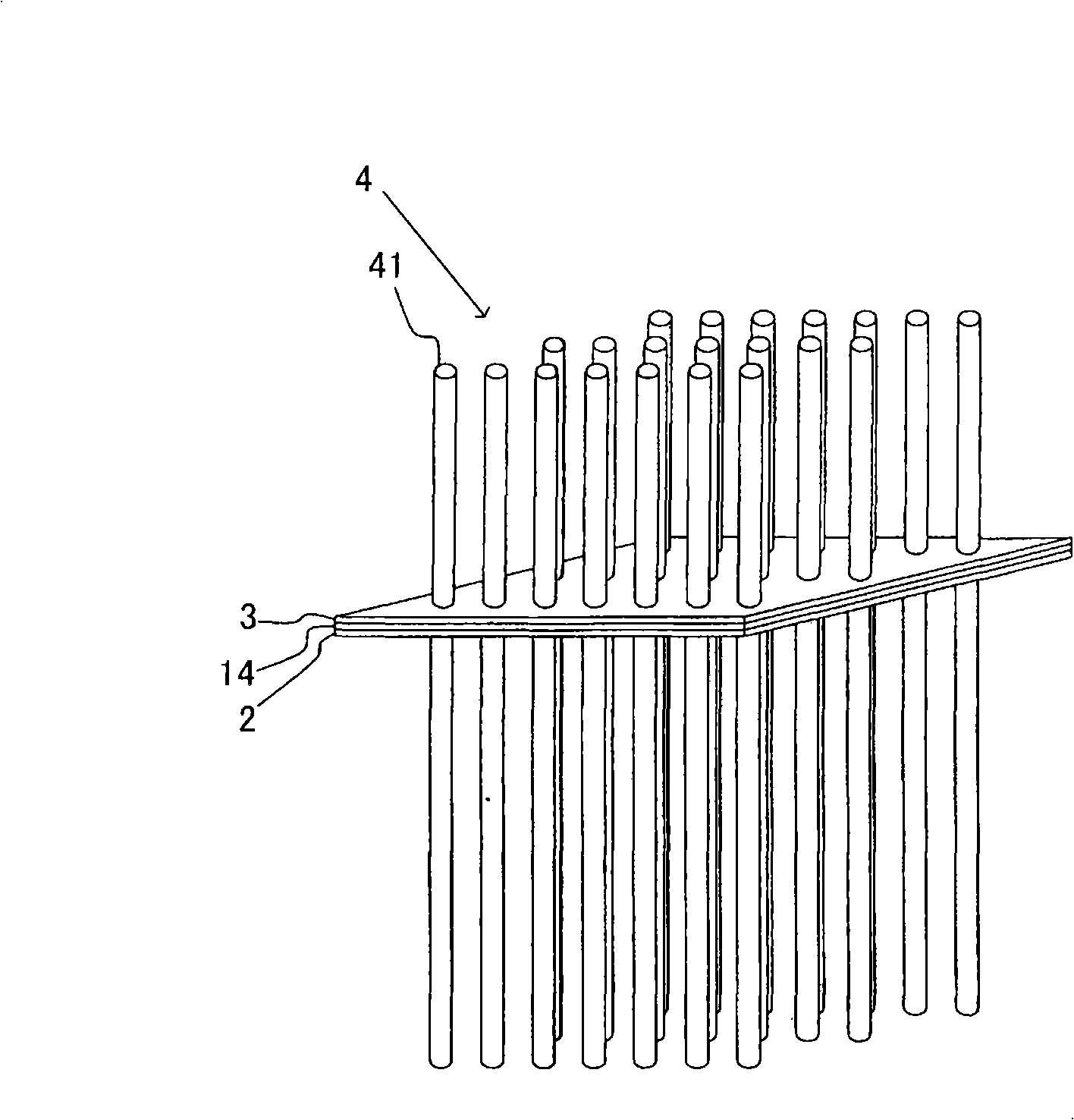

[0015] Hereinafter, a structural example of the heat recovery device will be described with reference to the drawings. The heat recovery device here is used to ventilate the multi-stage firing furnace used in the manufacturing process of liquid crystal display panels. The exhaust gas from the multi-stage kiln contains organic components generated by the evaporation of binders and the like. The heat recovery device discharges the waste gas to the outside of the furnace and draws fresh air into the furnace.

[0016] Fig. 1 is a side sectional view of a heat recovery device. Shown in the figure is a heat recovery device 100 of a fixed configuration. In addition, moving rollers or the like may be provided on the bottom surface of the heat recovery device 100 to move the heat recovery device 100 .

[0017] The heat recovery device 100 has an outer casing 1 . The interior of the outer casing 1 is divided into a control chamber 11 , a main preheating chamber 12 and a secondary pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com