Profound hypothermia discharger adopting full carbon aerogel and stirling cryocooler

A carbon airgel and deep low temperature technology, which is applied in the direction of refrigerators, refrigeration and liquefaction, compressors, etc., can solve the problems of large spanning temperature range of the ejector, low efficiency of refrigerators, and decreased specific heat capacity, so as to improve stability and Reliability, improve the efficiency of the whole machine, reduce the effect of heat leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

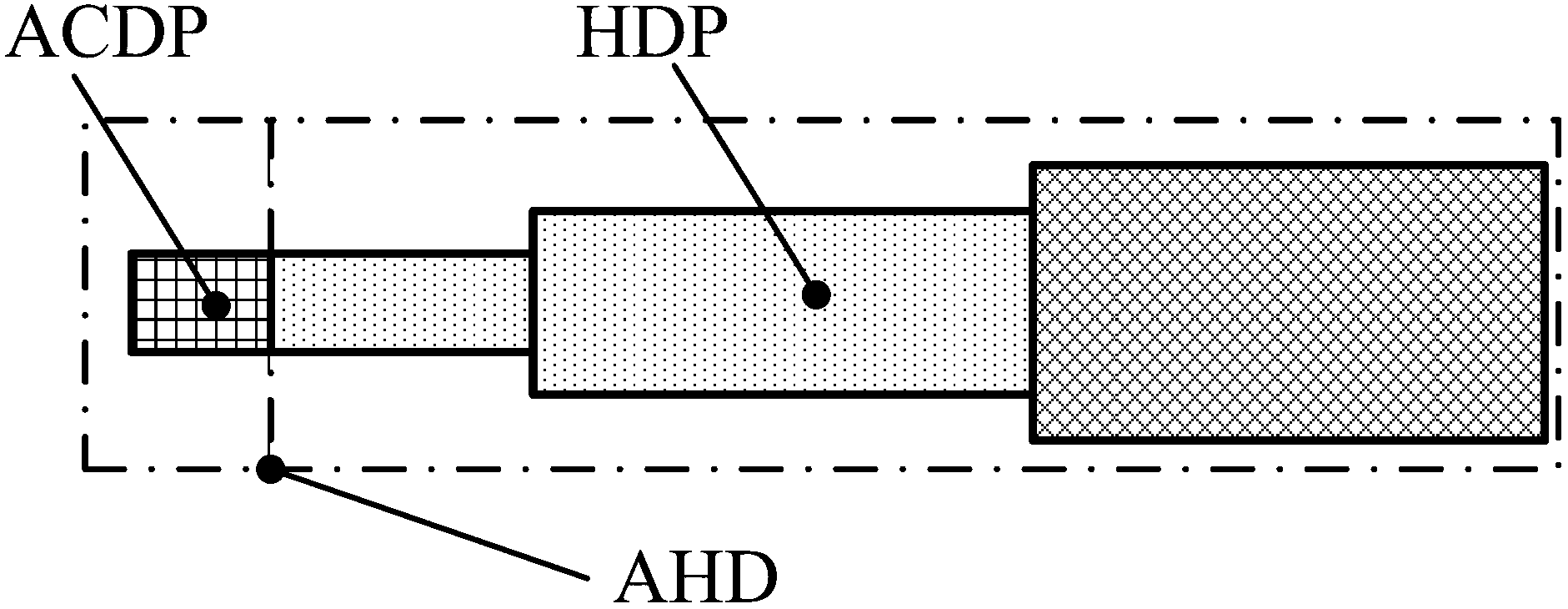

[0043] refer to figure 1 , a cryogenic ejector AHD adopting all-carbon aerogel, comprising a shell, a heat recovery filler filled in the shell, an adsorption layer is provided at the cold end of the cryogenic ejector AHD, and the adsorption layer is made of all-carbon Airgel composition. The shell is composed of thin-walled stainless steel tubes, which are filled with heat recovery fillers, and the adsorption layer is adhered to the cold end of the deep and low temperature ejector AHD by low temperature glue. In the figure, the deep and low temperature ejector AHD is divided into high temperature section HDP and low temperature section ACDP. The high temperature section HDP is suitable for the temperature range of 10-300K, the low temperature section ACDP is suitable for the temperature range of 10K and below 10K, and the adsorption layer is the low temperature section ACDP.

Embodiment 2

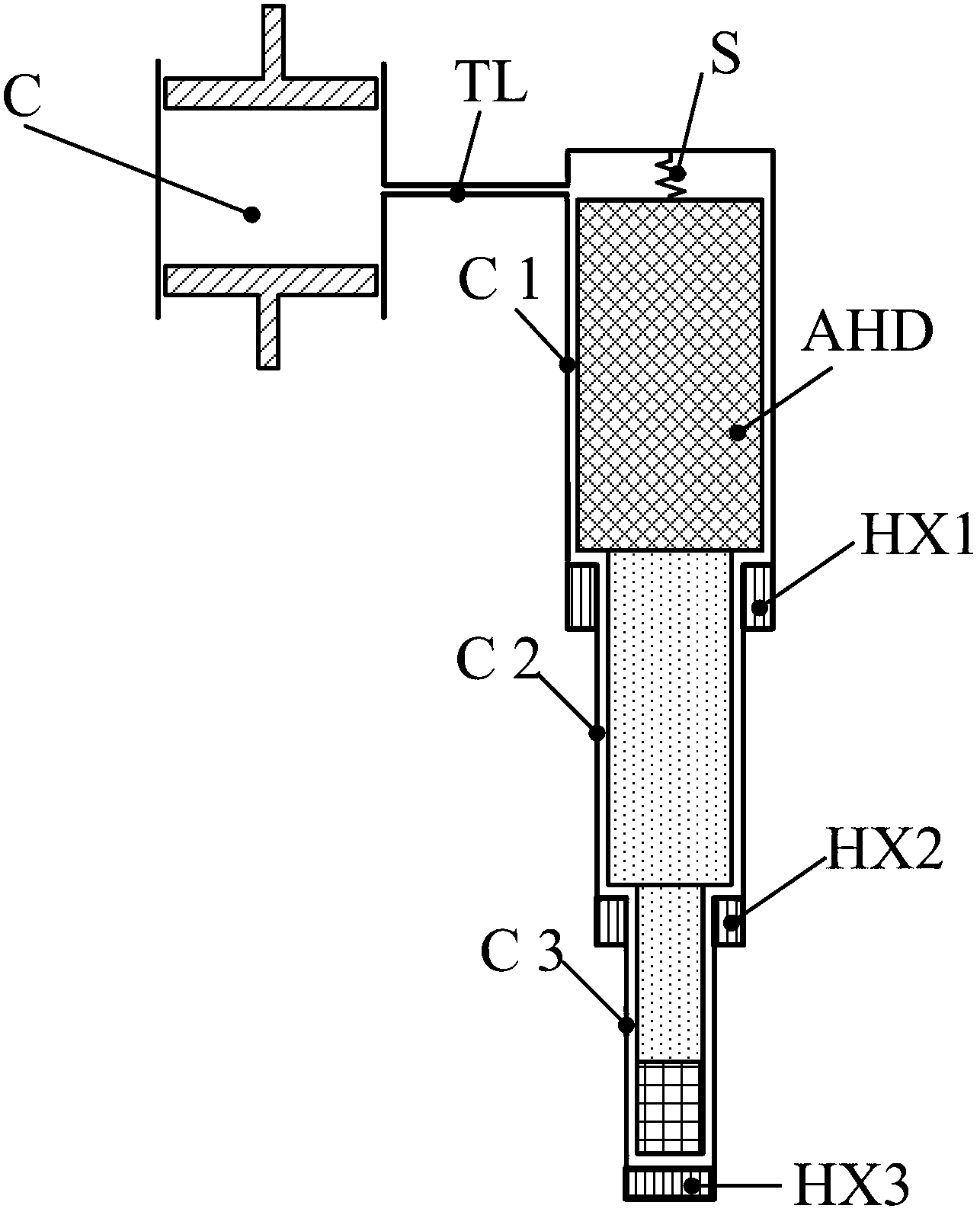

[0045] refer to figure 2 , a Stirling refrigerator, including a compressor C and a cold finger, the cold finger includes a transfer tube TL, a spring S, a deep-low temperature ejector AHD using all-carbon airgel, a first-stage cylinder C1, a first-stage cold End heat exchanger HX1, second stage cylinder C2, second stage cold end heat exchanger HX2, third stage cylinder C3 and third stage cold end heat exchanger HX3.

[0046] The connection relationship of the above-mentioned components is as follows: the compressor C is sequentially connected to the first-stage cylinder C1, the first-stage cold-end heat exchanger HX1, the second-stage cylinder C2, the second-stage cold-end heat exchanger HX2, and the second-stage cylinder through the transmission pipe TL. The third-stage cylinder C3 is connected to the third-stage cold-end heat exchanger HX3; the first-stage cylinder C1, the first-stage cold-end heat exchanger HX1, the second-stage cylinder C2, the second-stage cold-end heat ...

Embodiment 3

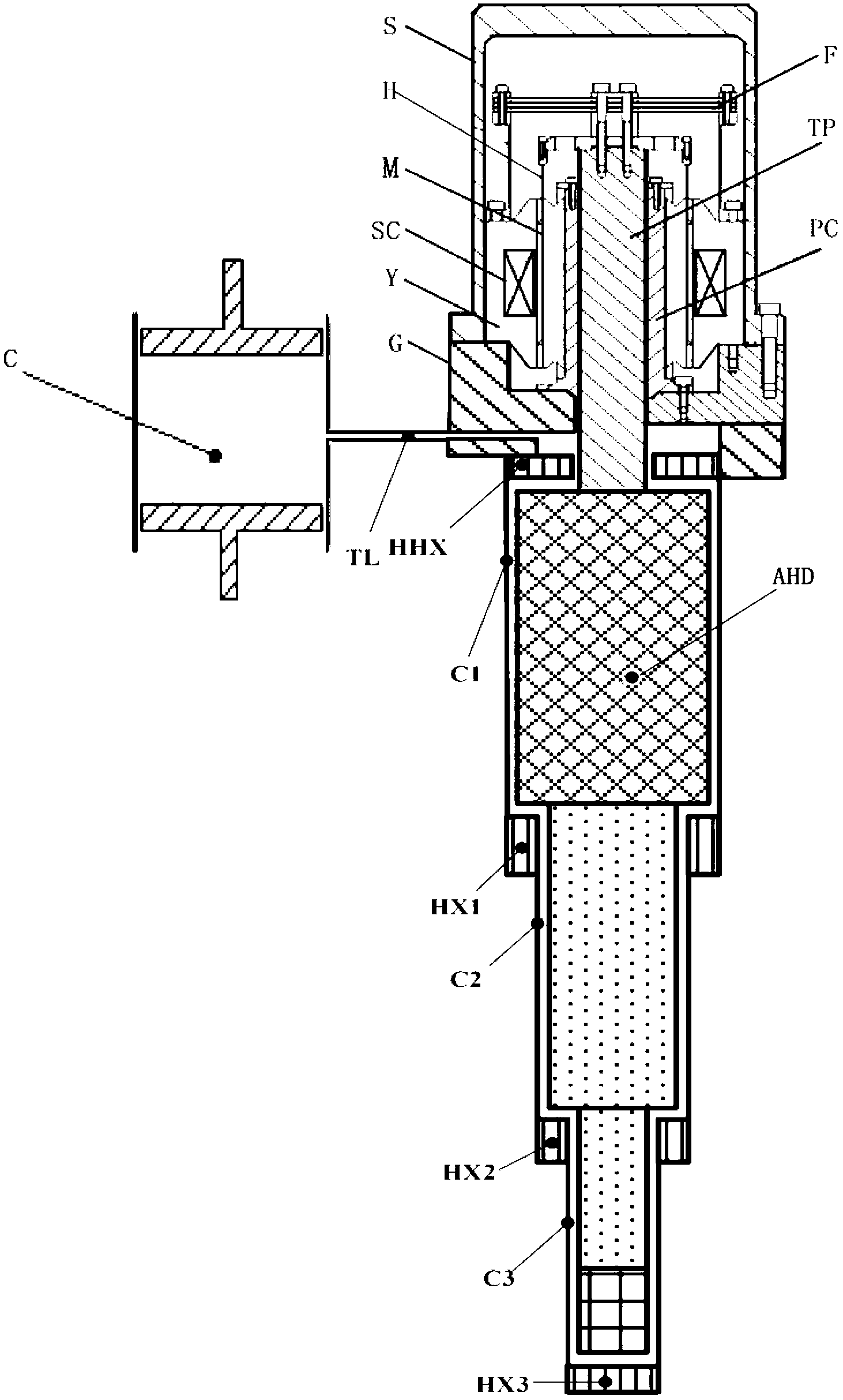

[0050] refer to image 3 , a Stirling refrigerator includes a compressor C with a transfer tube TL, a cold finger, and an expander; the cold finger includes a hot-end heat exchanger HHX, a deep-low temperature ejector AHD using all-carbon airgel, the first Stage cylinder C1, first stage cold end heat exchanger HX1, second stage cylinder C2, second stage cold end heat exchanger HX2, third stage cylinder C3 and third stage cold end heat exchanger HX3; expander includes expansion Machine shell S, ring fixed frame G, cylinder body PC, leaf spring F, coil SC, piston TP, yoke iron Y, permanent magnet M, permanent magnet support H.

[0051] The connection relationship of the above-mentioned components is as follows: the compressor C is connected to the expander through the transmission pipe TL, and the expander is sequentially connected to the hot-end heat exchanger HHX, the first-stage cylinder C1, the first-stage cold-end heat exchanger HX1, and the second-stage Cylinder C2, secon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com