Improved low temperature heat pipe heat exchanger

A heat pipe heat exchanger, an improved technology, applied to indirect heat exchangers, lighting and heating equipment, etc., can solve the problems of wasting heat energy, polluting fresh air, and low heat exchange efficiency, so as to improve heat recovery efficiency and reduce energy The effect of improving the consumption and heat transfer coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

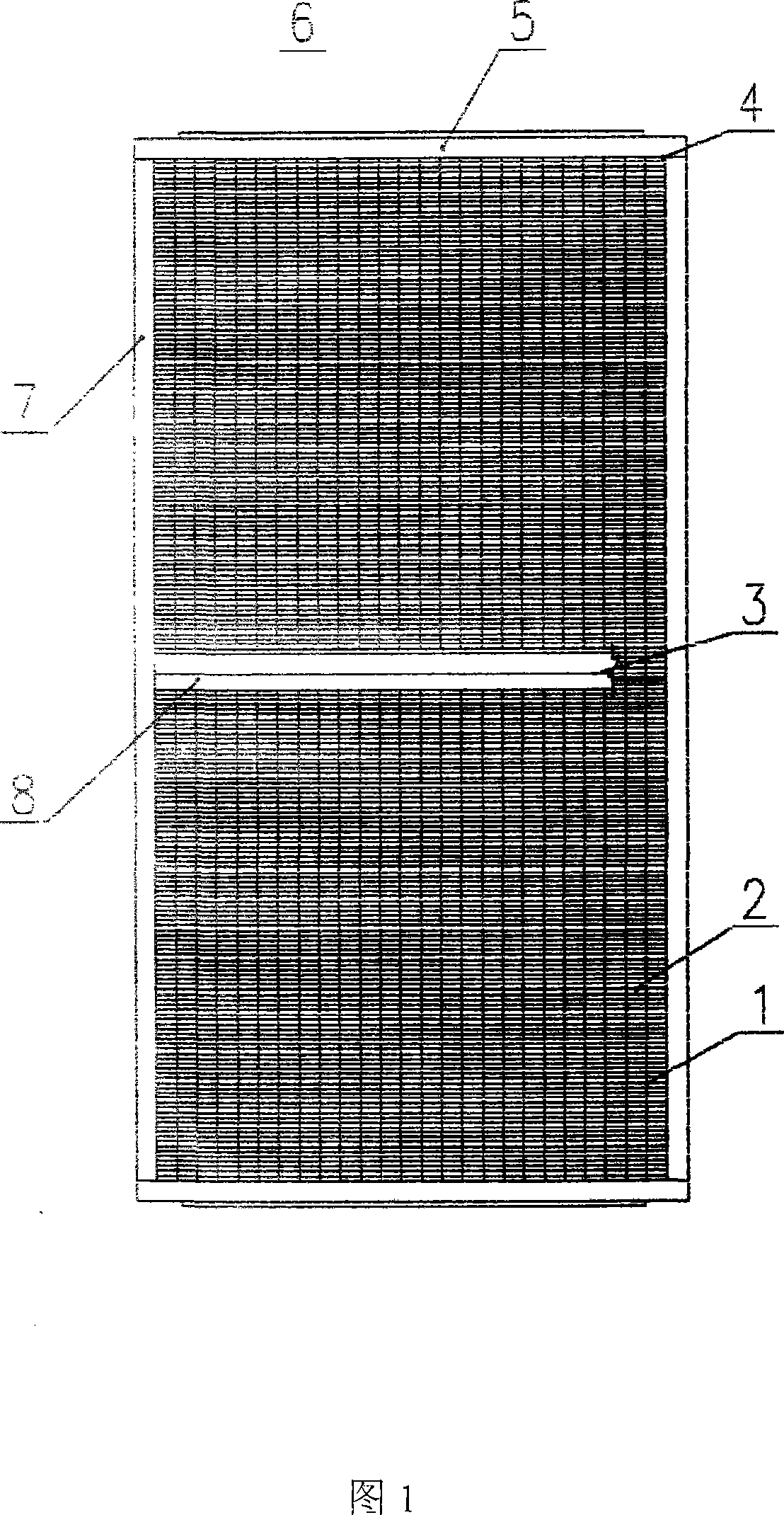

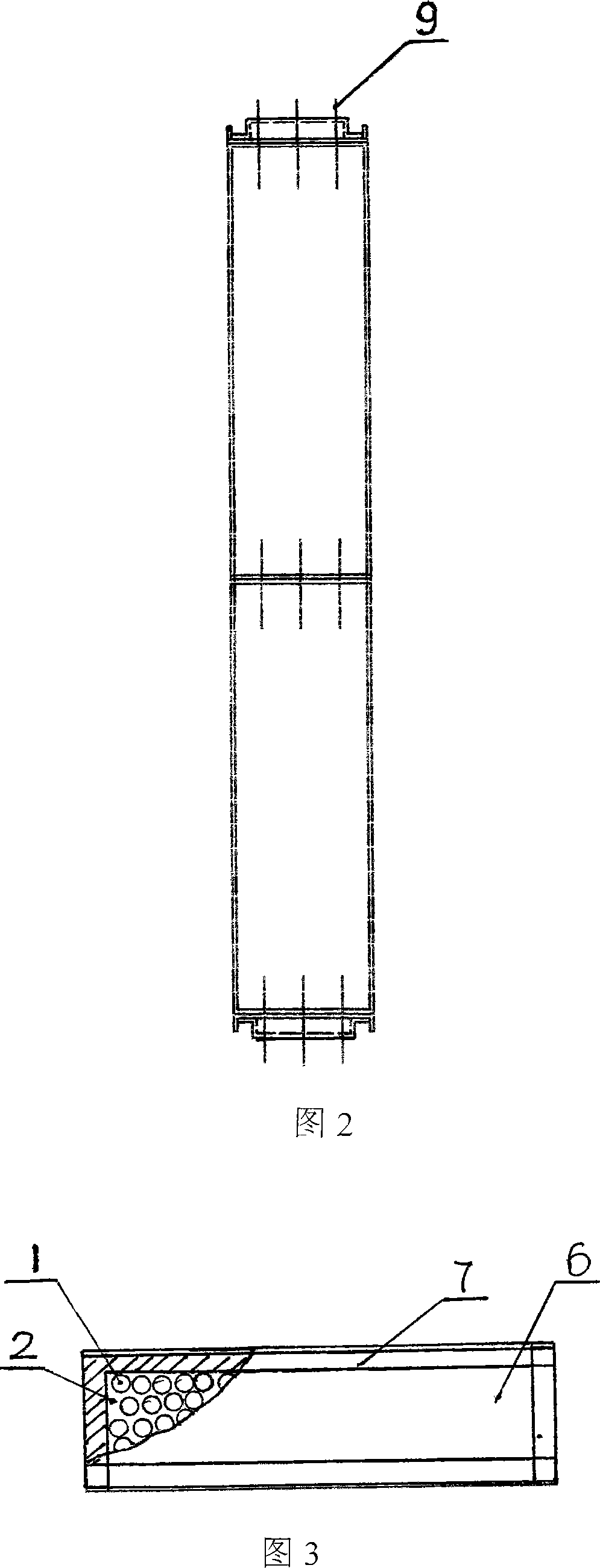

[0017] The present invention will be further described below in conjunction with the accompanying drawings. As can be seen from Fig. 1-Fig. , end plate 4, side frame 5, cover plate 6, upper and lower frame 7, connecting plate 8 and fastening bolt 9, and multiple rectangular aluminum plate fins 2 are superimposed into a rectangular cube form with gaps, in the middle of the rectangular cube An aluminum middle partition 3 is set, and the distance between the fins 2 of each aluminum plate is 3 millimeters. There are a plurality of regularly arranged through holes corresponding to the aluminum fins 2 and the aluminum middle partition 3, and the hole distance is 50 millimeters. The hollow aluminum tube 1 is inserted into the through hole, and the hollow aluminum tube 1 is expanded by the tube expanding machine to form a tight fit with the multi-piece rectangular aluminum fins 2 and the aluminum partition 3, and the end plates 4 corresponding to the through holes are matched at both e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com