Heat-insulation sound-insulation light-weight high-strength aerated concrete building block and producing method thereof

A technology of heat and sound insulation and aerated blocks, which is applied in the field of building wall materials, can solve the problems of uneven pore size and distribution, uneven distribution of ceramsite, and high product density, so as to reduce performance dispersion, shrink strength, Good heat insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

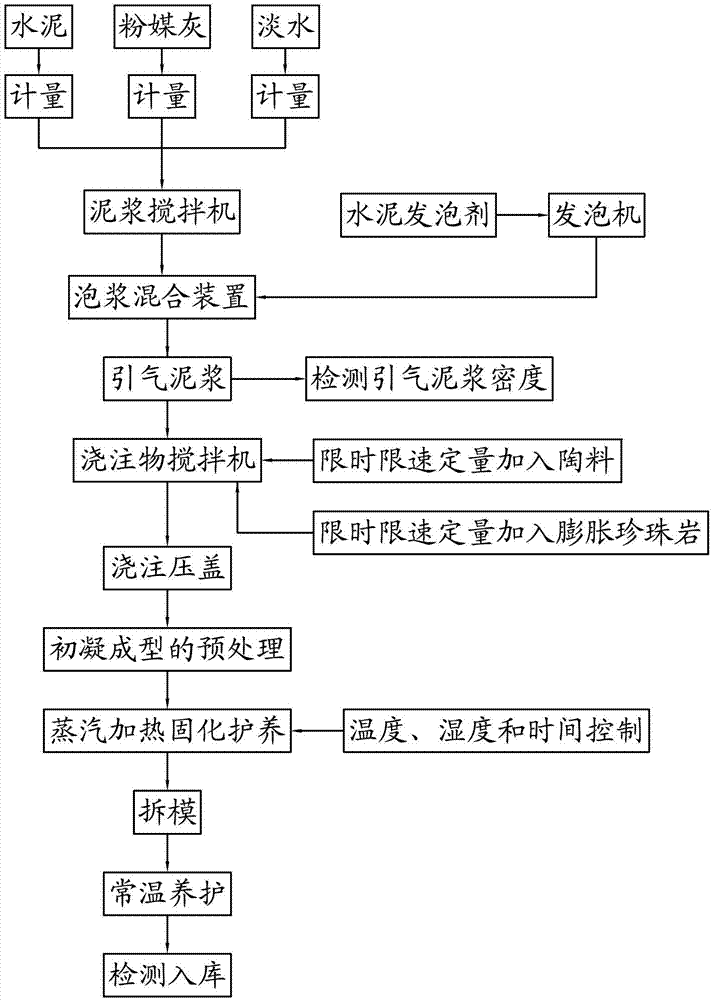

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1: A heat-insulating, sound-insulating, light-weight, high-strength concrete aerated block is formed by molding, casting and solidifying special concrete materials, and the density of the special concrete materials is 900Kg / m 3 ~1000Kg / m 3 , the preparation components of the special concrete material and the proportioning ratio of parts by weight thereof are:

[0036] Component

Ceramsite

expanded perlite

cement foaming agent

parts by weight

25

31

15

7

20

2

[0037] Among them, the strength grade of cement is 42.5.

[0038] The performance index comparison table of the obtained concrete aerated block and the ceramsite concrete aerated block of the same strength specification is as follows:

[0039] Performance

Embodiment 2

[0040]Example 2: A heat-insulating, sound-insulating, light-weight, high-strength concrete aerated block is formed by molding, casting and solidifying special concrete materials with a density of 900Kg / m 3 ~1000Kg / m 3 , the preparation components of the special concrete material and the proportioning ratio of parts by weight thereof are:

[0041] Component

cement

Ceramsite

expanded perlite

cement foaming agent

parts by weight

28

27

18

6

18.8

2.2

[0042] Among them, the strength grade of cement is 42.5.

[0043] The performance index comparison table of the obtained concrete aerated block and the ceramsite concrete aerated block of the same strength specification is as follows:

[0044] Performance

Embodiment 3

[0045] Embodiment 3: A heat-insulating, sound-insulating, light-weight, high-strength concrete aerated block is formed by molding, casting and solidifying special concrete materials with a density of 900Kg / m 3 ~1000Kg / m 3 , the preparation components of the special concrete material and the proportioning ratio of parts by weight thereof are:

[0046] Component

cement

Ceramsite

expanded perlite

fresh water

cement foaming agent

parts by weight

29

26

15

6.1

21

2.9

[0047] Among them, the strength grade of cement is 42.5.

[0048] The performance index comparison table of the obtained concrete aerated block and the ceramsite concrete aerated block of the same strength specification is as follows:

[0049] Performance

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com