High flame retardant polyurethane rigid foam outer wall thermal insulation system

A technology of polyurethane rigid foam and exterior wall insulation, which is applied in the field of building exterior wall insulation materials and high flame-retardant polyurethane rigid foam exterior wall insulation systems, can solve the problem of poor adhesion between the moisture-proof layer and the base wall, and the inability to use ceramic tiles. Decorative materials, easy to fall off and other problems, to achieve excellent chemical stability, improve thermal insulation effect, improve the effect of shrinkage and collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

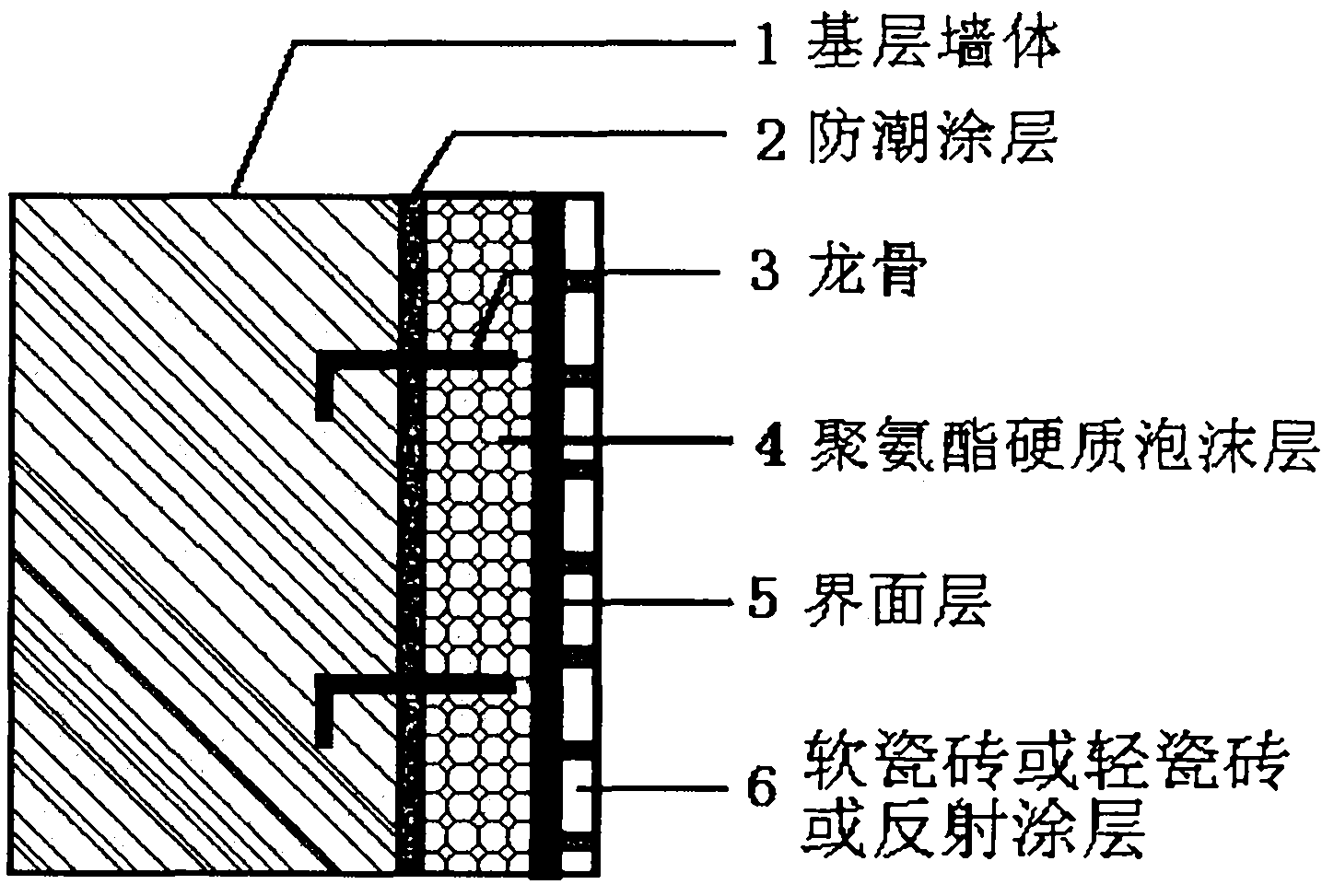

[0074] The invention provides a high flame-retardant polyurethane rigid foam external wall insulation system, which can be realized through the following technical route:

[0075] (1) Install keels and connectors on the base wall, if attached figure 1 As shown, coat the base wall surface with a polyurethane base coat and an adhesion-promoting layer;

[0076] (2) Prepare component A of polyurethane rigid foam composition, spray component A of composite material and component B of polyisocyanate to the base wall through a foaming machine, foam and mature for 24 to 48 hours, and apply rigid polyurethane foam Smooth the surface; see Table 1 to Table 3 for examples of polyurethane rigid foam formulations:

[0077] 1# Table 1

[0078] raw material

parts by mass

source

Polyether polyol 4110

60

Fushun Jiahua Chemical Co., Ltd.

Polyether polyol Multranol 9181

10

Bayer MaterialScience

Soybean Oil Polyol Soyoyl R137

30

Ur...

Embodiment 2

[0090] Embodiment 2 performance test experiment

[0091] 1. Polyurethane rigid foam performance test

[0092] Carry out performance test to 1#~3# polyurethane rigid foam samples in the above-mentioned embodiment 1, the performance test method refers to GB / T 3399 plastic thermal conductivity test method-protected hot plate method, GB / T 8811 rigid foam plastic dimensional stability Test method, GB / T 8810 rigid foam water absorption test method. The test results are shown in Table 4:

[0093] Table 4

[0094] sample

Flame retardant

Closure rate

water absorption

1#

Self-extinguishing, V-0 level

0.021W / (m·K)

98.5%

0.3%

2#

Self-extinguishing, V-0 level

0.025W / (m·K)

95.3%

2.1%

3#

Self-extinguishing, V-0 level

0.017W / (m·K)

96.4%

1.1%

sample

Dimensional stability at 80°C

Dimensional stability at -30°C

Tensile Strength ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com