Low-smoke zero-halogen ceramic fireproof cable material and preparation method thereof

A refractory cable, ceramic technology, applied in plastic/resin/wax insulators, organic insulators and other directions, can solve problems such as unfavorable enlarged production, limited application scope, low production efficiency, etc., achieve fast crusting speed, excellent mechanical properties, The effect of low smoke production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

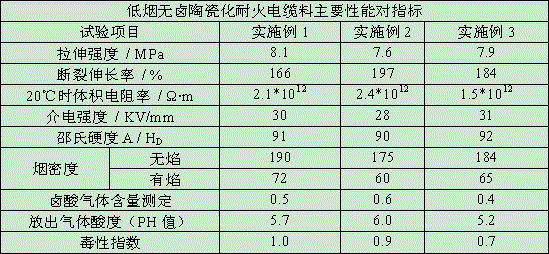

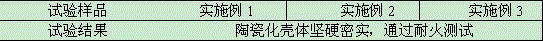

Embodiment 1

[0038] Example 1: A low-smoke halogen-free ceramic refractory cable material is composed of the following materials in parts by weight: 50 parts of ethylene-vinyl acetate copolymer, 40 parts of ethylene-α-propylene copolymer, ethylene-α-propylene The copolymer is EPDM4725P produced by Dow Company of the United States, 10 parts of amorphous polyolefin grafted with maleic acid, and the amorphous polyolefin grafted with maleic acid is JY035 produced by Shanghai Jiuju Company, and the grafting rate of maleic anhydride is 1.0% , 50 parts of mica powder, 50 parts of ceramic powder, 50 parts of glass powder with a melting point of 500°C, 50 parts of magnesium hydroxide, 5 parts of calcium oxide, 8 parts of zinc oxide, 10 parts of melamine cyanurate, and 0.5 parts of antioxidant 1010 parts, silane coupling agent A-1721 parts, silicone masterbatch 3 parts.

[0039] The ethylene-vinyl acetate copolymer is EVA2803 produced by French Akema company, the content of vinyl acetate is 28%, and...

Embodiment 2

[0041] Example 2: A low-smoke halogen-free ceramic refractory cable material is composed of the following materials in parts by weight: 40 parts of ethylene-vinyl acetate copolymer, 40 parts of ethylene-α-octene copolymer, the ethylene-α- The octene copolymer is DF8200 produced by Mitsui Corporation of Japan, 10 parts of amorphous polyolefin grafted with maleic anhydride, and the amorphous polyolefin grafted with maleic anhydride is JY035 produced by Shanghai Jiuju Company, and the graft ratio of maleic anhydride is 1.5 %, 60 parts of mica powder, 40 parts of ceramic powder, 30 parts of glass powder with a melting point of 750°C, 40 parts of magnesium hydroxide, 10 parts of calcium oxide, 5 parts of zinc oxide, 9 parts of melamine cyanurate, and 1010 antioxidants 1.5 parts, titanate coupling agent A-1722 parts, silicone masterbatch 5 parts.

[0042] The ethylene-vinyl acetate copolymer is EVA40L03 produced by DuPont, USA, the vinyl acetate content is 40%, and the melt flow rat...

Embodiment 3

[0044] Example 3: A low-smoke halogen-free ceramic refractory cable material, which consists of the following materials in parts by weight: 50 parts of ethylene-vinyl acetate copolymer, 40 parts of ethylene-α-octene copolymer, the ethylene-α- The octene copolymer is DF8200 produced by Mitsui Corporation of Japan, 10 parts of amorphous polyolefin grafted with maleic anhydride, and the amorphous polyolefin grafted with maleic anhydride is JY035 produced by Shanghai Jiuju Company, and the graft ratio of maleic anhydride is 1.5 %, 40 parts of mica powder, 60 parts of ceramic powder, 40 parts of glass powder with a melting point of 800°C, 60 parts of magnesium hydroxide, 12 parts of calcium oxide, 9 parts of zinc oxide, 12 parts of melamine cyanurate, 10101.5 parts of antioxidant , 1.5 parts of silane coupling agent A-172, 7 parts of silicone masterbatch.

[0045] The ethylene-vinyl acetate copolymer is EVA2803 produced by French Akema company, the content of vinyl acetate is 28%, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com