Patents

Literature

45results about How to "Enhanced ceramic performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

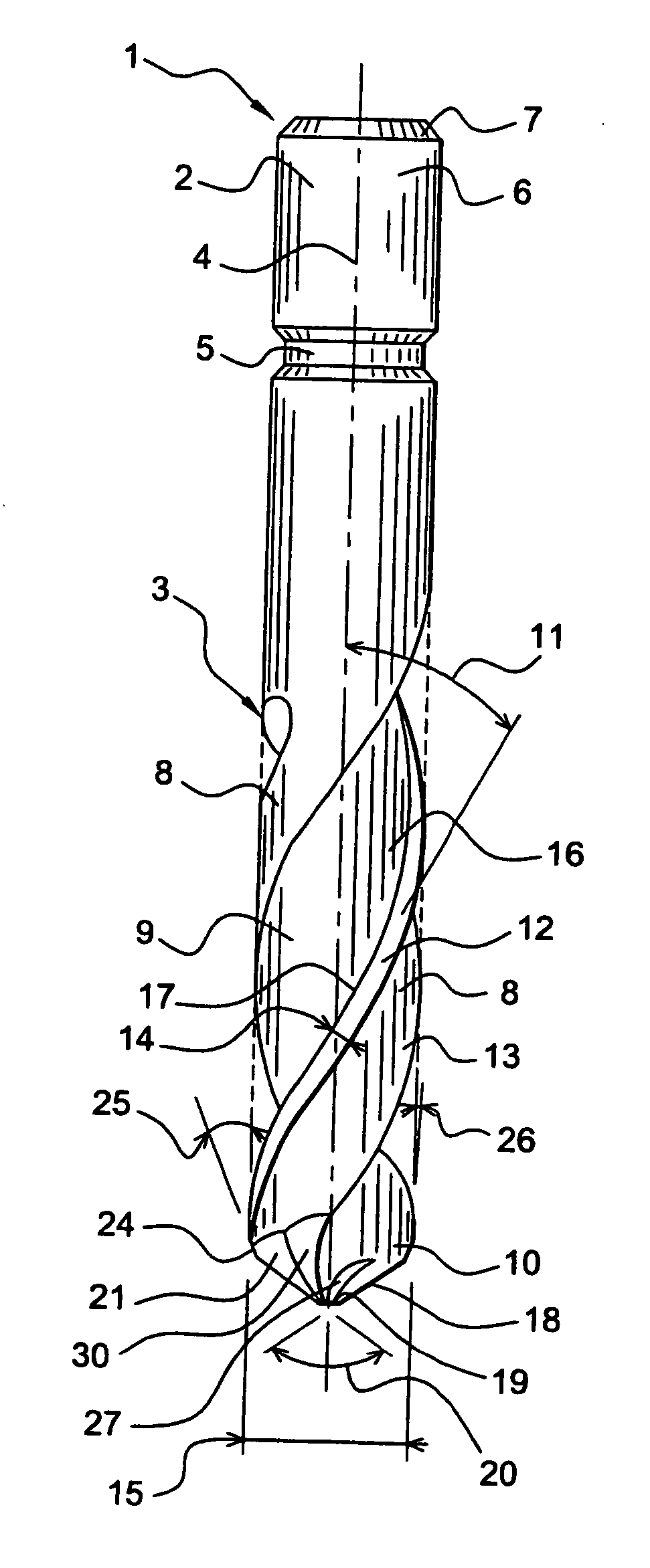

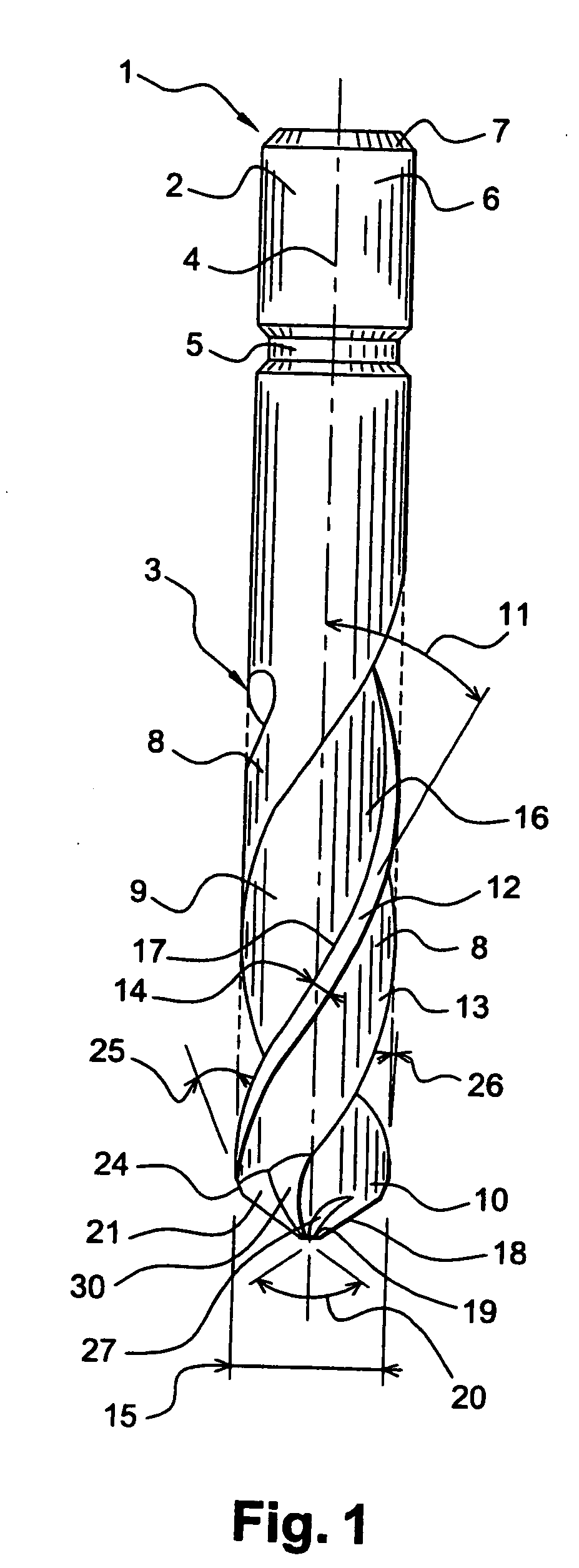

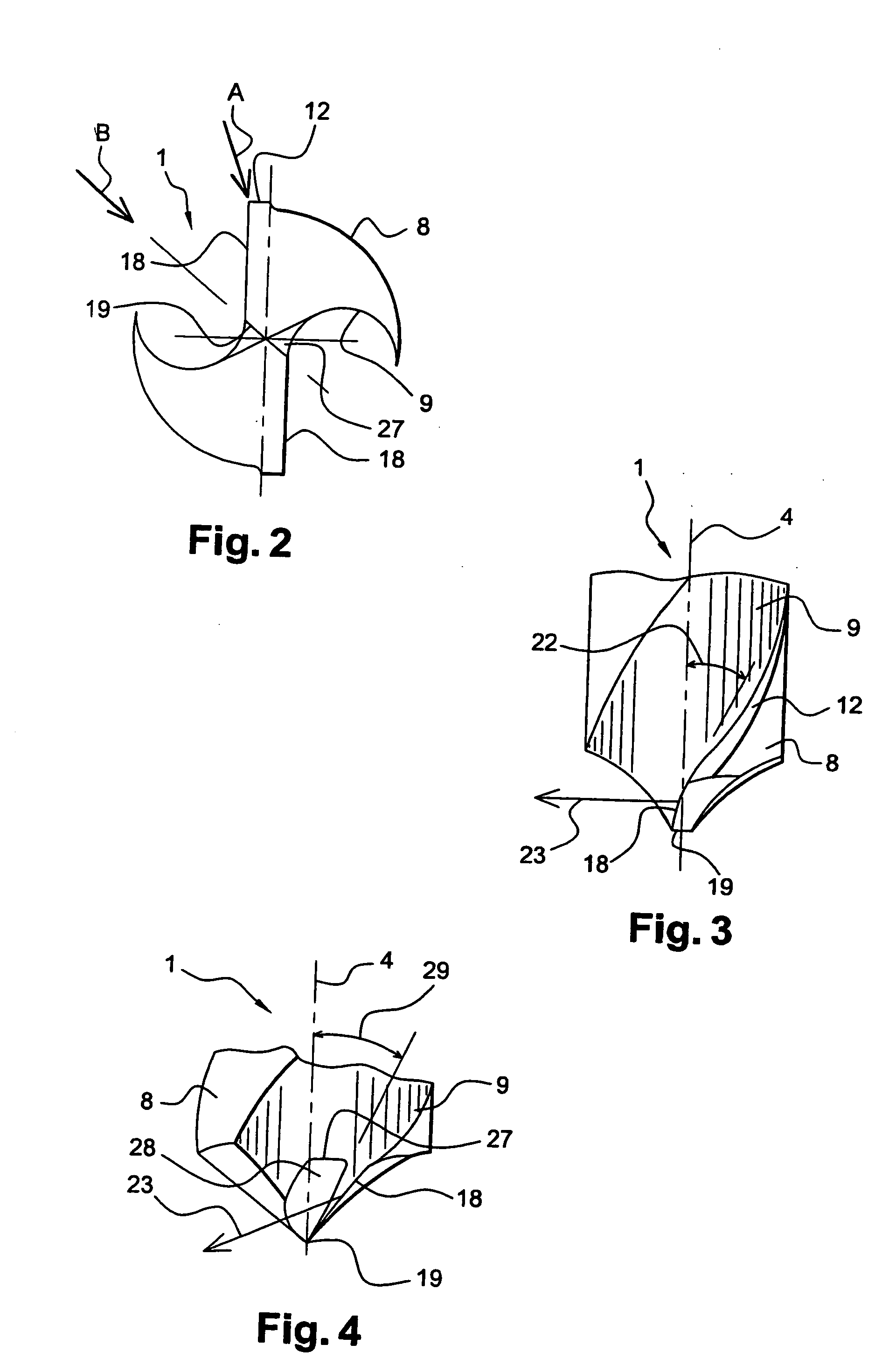

Ceramic bit for high speed drilling

ActiveUS20050135889A1Technically inexpensiveTechnically simpleWood turning toolsTransportation and packagingEngineeringHigh speed drilling

A ceramic drill bit comprising a cylindrical shank and a shaped portion extending axially in line with the shank and having a free end forming the tip of the bit, a relief face extending from each main cutting edge with a relief angle lying in the range 4° to 10° approximately relative to a plane perpendicular to the axis of rotation of the bit, and two notches forming two secondary cutting faces extending from the central edge with positive cutting angles lying in the range 10 to 70 approximately relative to the axis of rotation of the bit.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

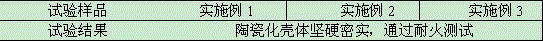

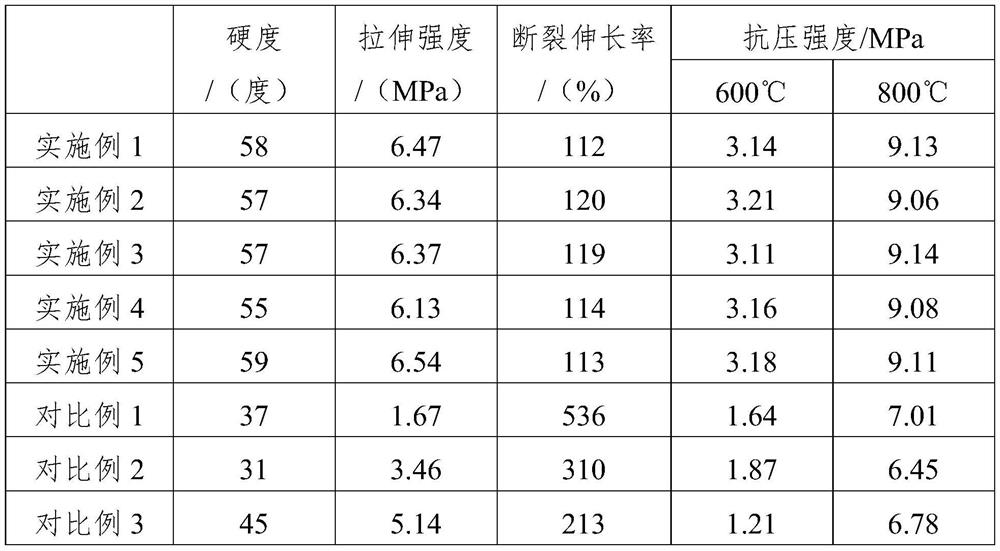

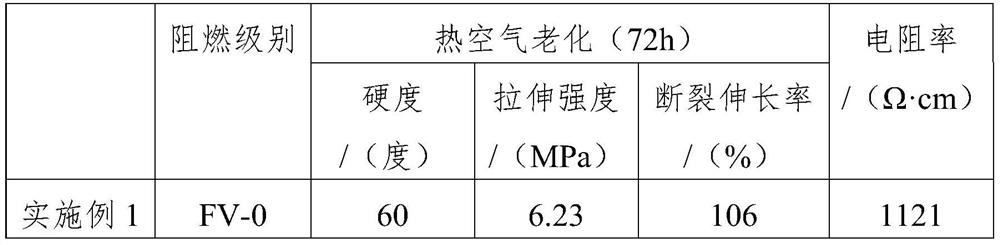

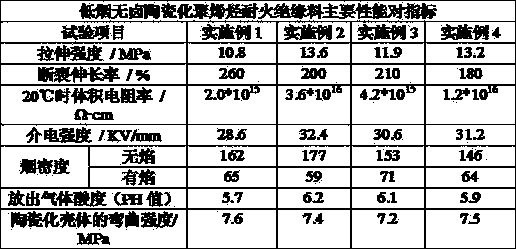

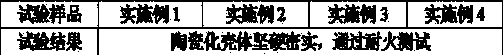

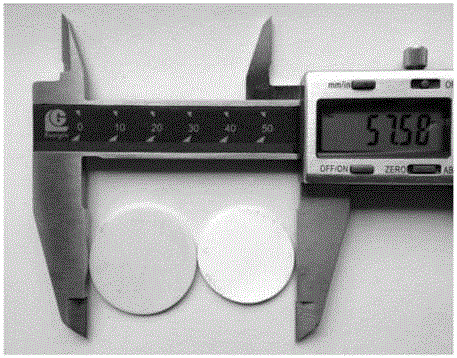

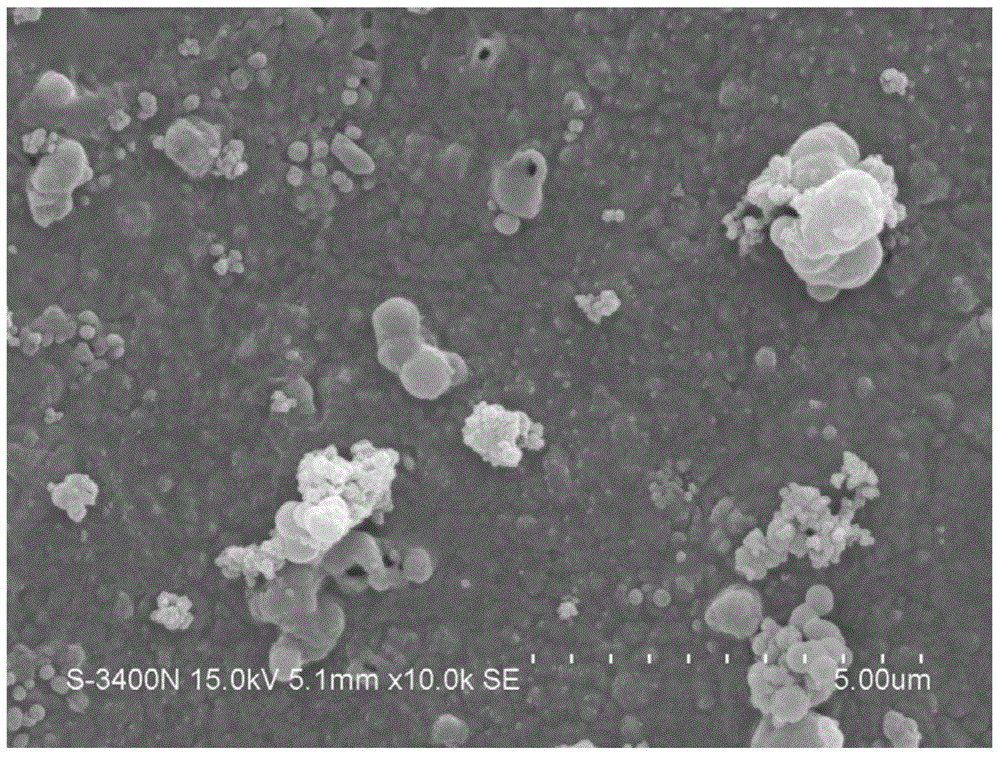

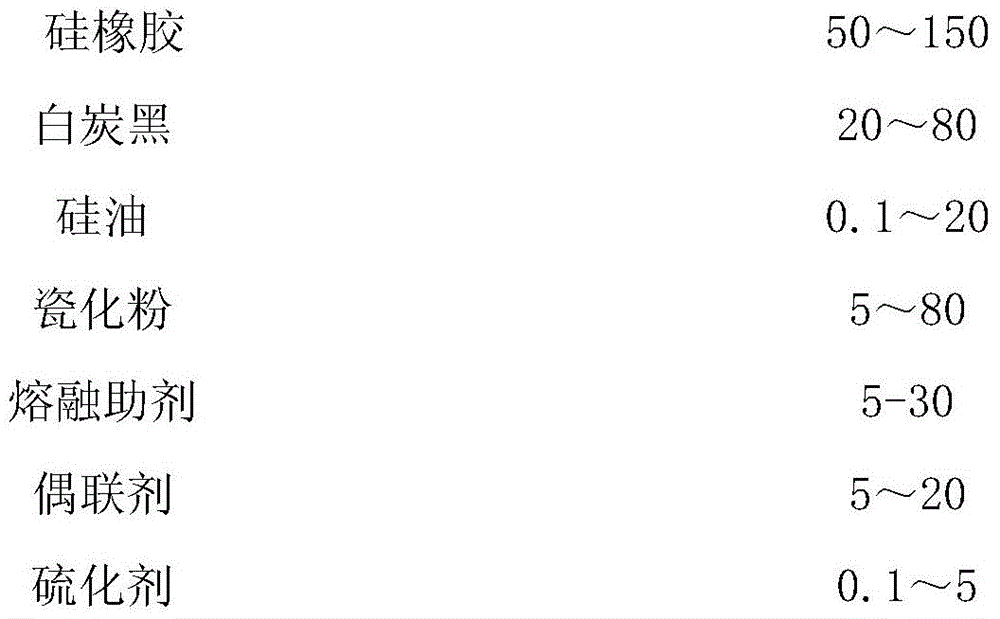

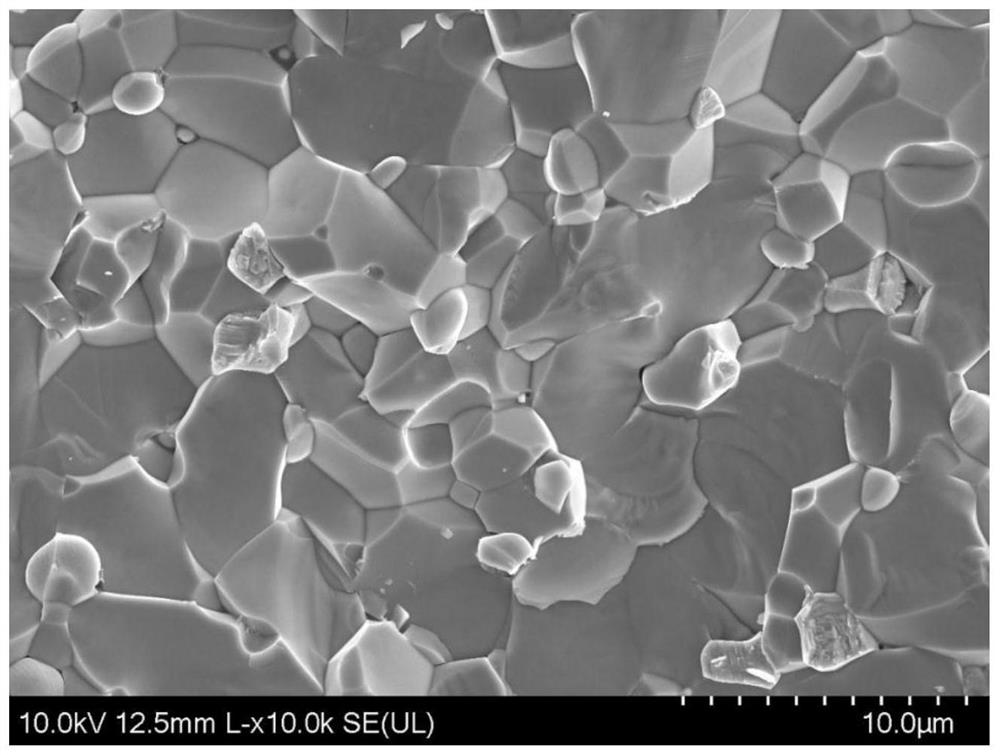

Environment-friendly ablation-resistant ceramic silicone rubber composite material and preparation method thereof

ActiveCN103923465AEnhanced ceramic performanceImprove mechanical propertiesVulcanizationPolymer science

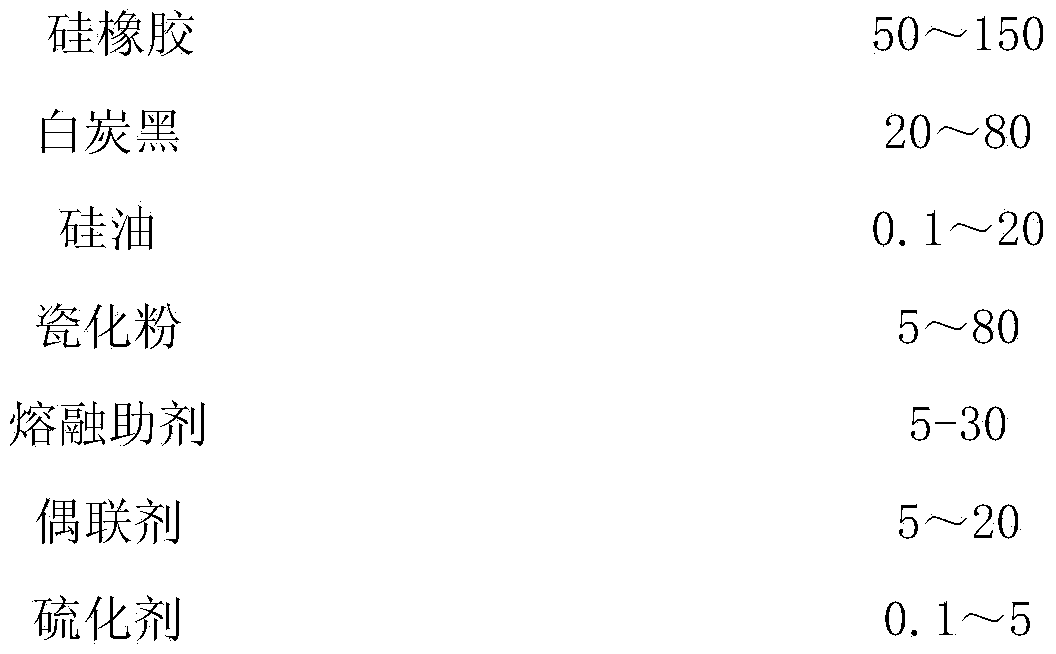

The invention relates to an environment-friendly ablation-resistant ceramic silicone rubber composite material and a preparation method thereof. The composite material consists of silicone rubber, white carbon black, vitrified powder, a fusion aid, silicone oil and a coupling agent. The composite material is prepared by the following steps: first, mixing 50-150 parts of silicone rubber, 5-80 parts of white carbon black, 5-20 parts of coupling agent, 2-80 parts of vitrified powder, 2-30 parts of fusion aid and 0.1-20 parts of silicone oil; then, adding 2-10 parts of vulcanizing agent, uniformly mixing to obtain a sheet; and finally, carrying out hot press molding on the obtained sizing material under the pressure of 10-15MPa and at 100-200 DEG C, and carrying out two-sectional vulcanization by virtue of hot air with temperature of 150-220 DEG C to obtain the ceramic silicone rubber composite material. According to the composite provided by the invention, the ceramic performance of the material is greatly improved while the mechanical property of the composite material is ensured, and therefore the composite material has a wide application range.

Owner:EAST CHINA UNIV OF SCI & TECH

Porcelainized fireproof and heat insulation foamed silicone rubber and preparation method thereof

The invention discloses porcelainized fireproof and heat insulation foamed silicone rubber and a preparation method thereof. The rubber comprises the following raw materials in parts by weight: 100 parts of base rubber, 10 to 60 parts of porcelain forming filler, 0.1 to 0.5 part of a platinum catalyst, 0.5 to 1.5 parts of silicone oil, 2 to 10 parts of a foaming agent, 0.1 to 0.5 part of a vulcanizing agent, and 0.1 to 0.4 part of a vulcanization accelerator. The foamed silicone rubber has good ceramic effect, does not have surface cracks, is hard in texture, keeps a complete foam structure, ensures that the volume retention rate is 85% or higher, and is excellent in fireproof performance.

Owner:WUHU YANGZHAN NEW MATERIAL TECH SERVICE CO LTD

Silicon nitride ceramic slurry, silicon nitride ceramic and preparation method and application thereof

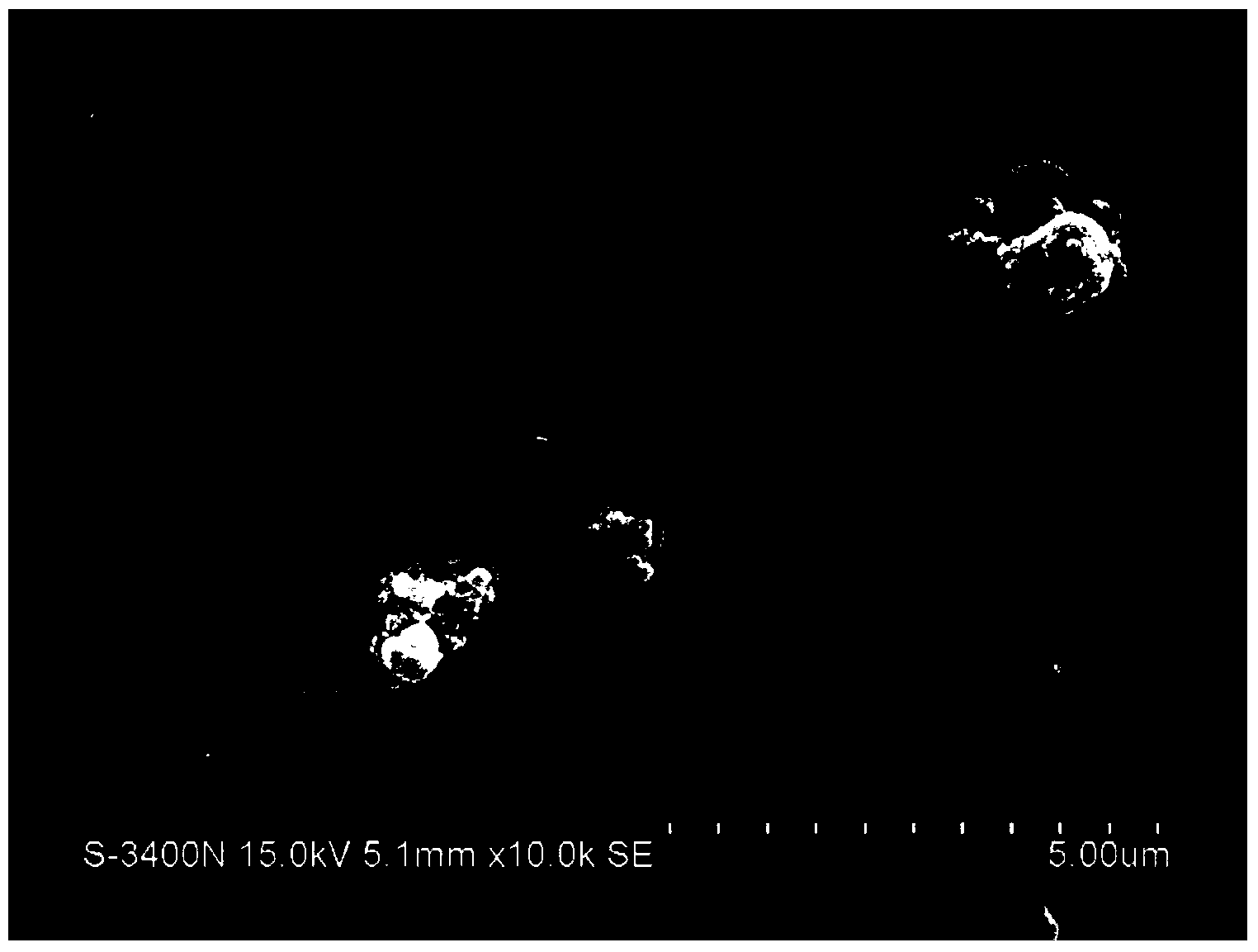

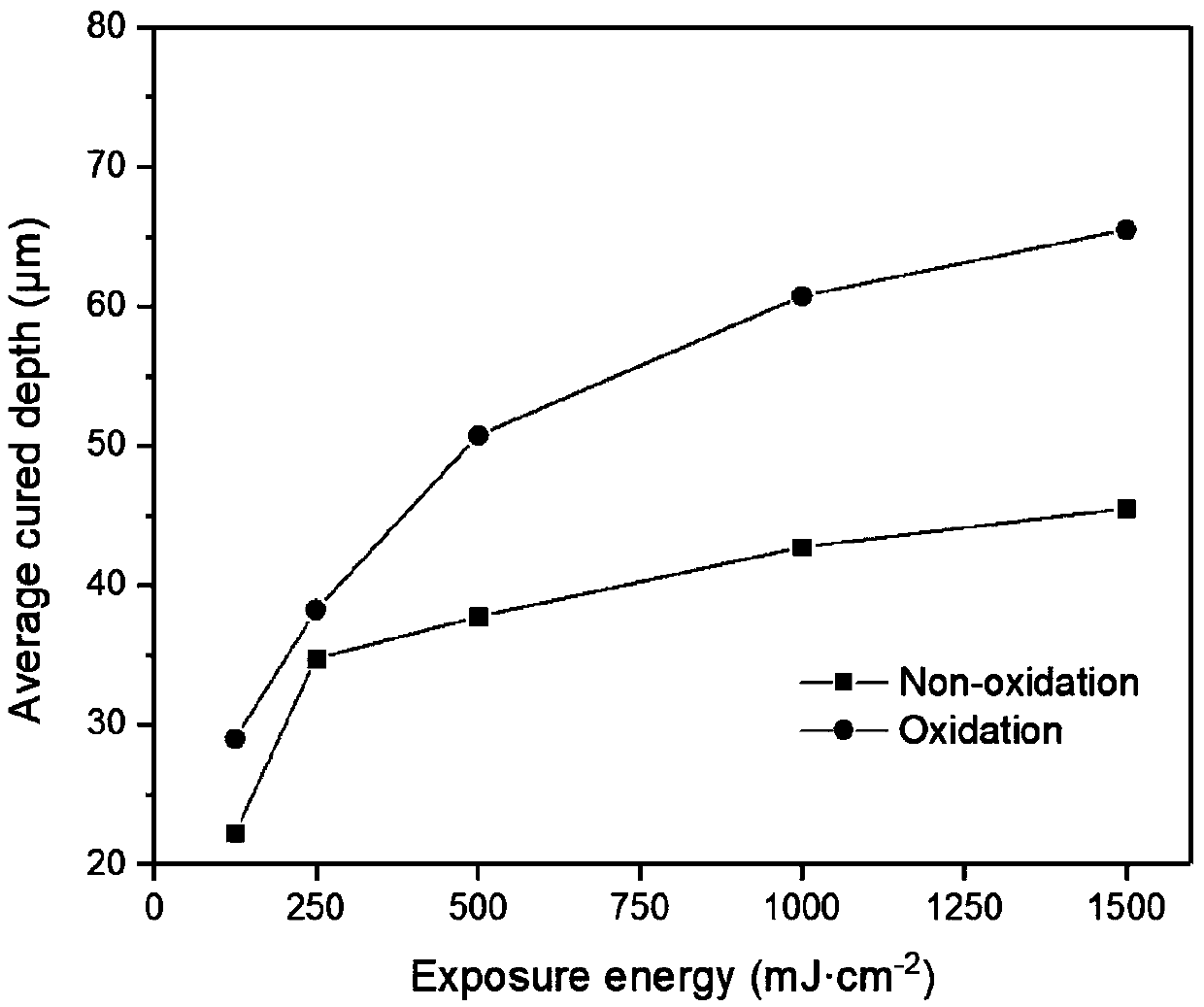

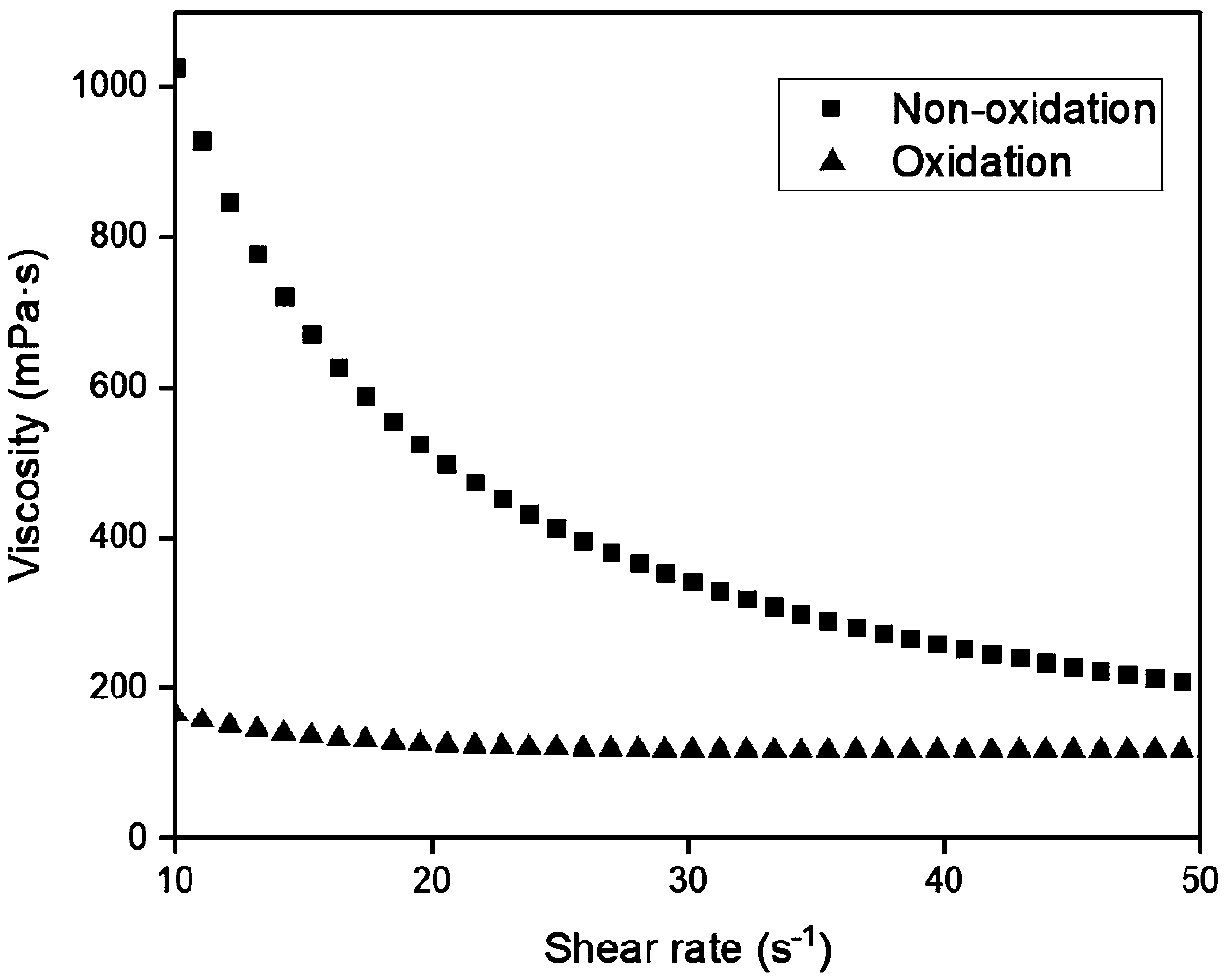

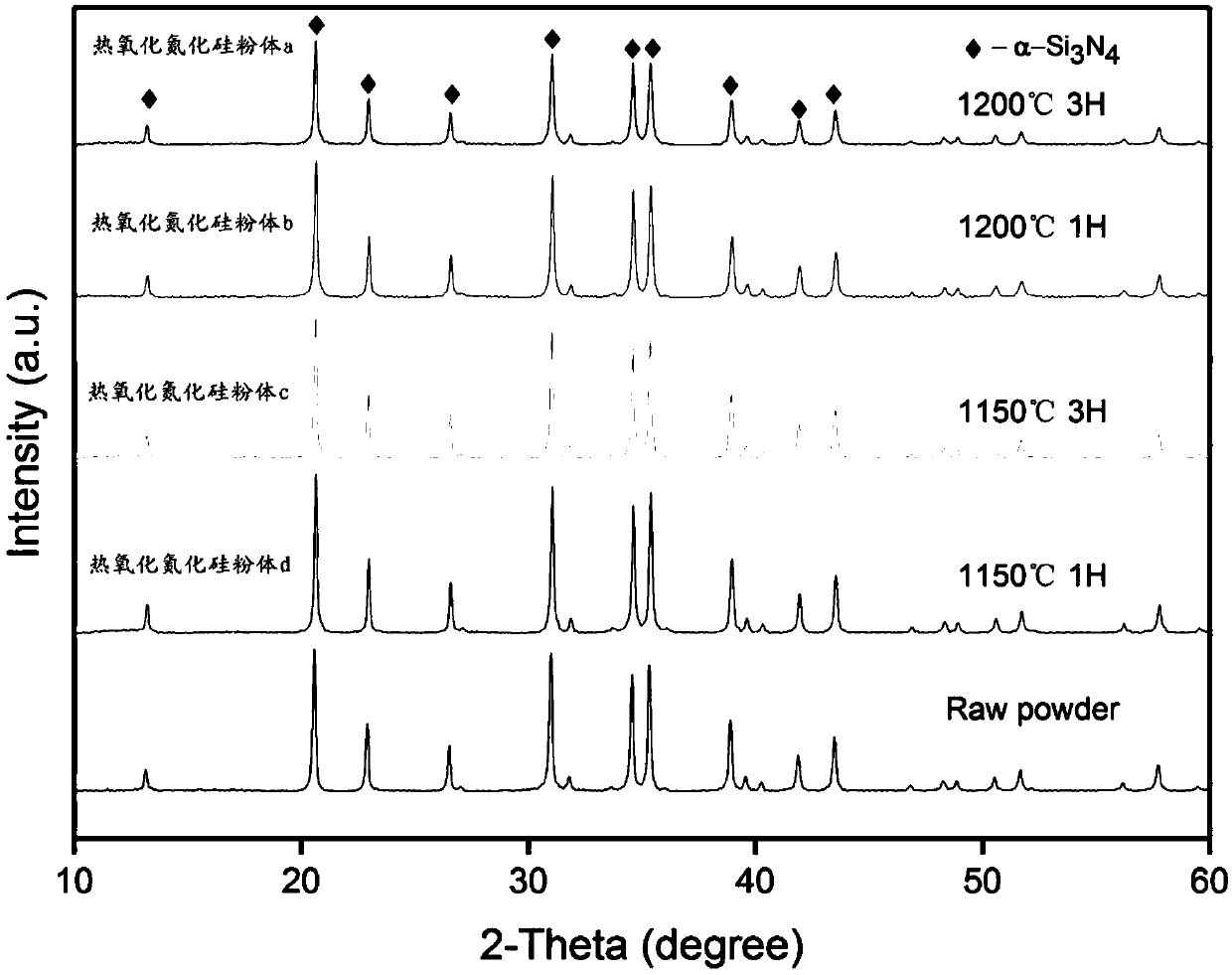

The invention belongs to the technical field of ceramic materials, and particularly relates to silicon nitride ceramic slurry, silicon nitride ceramic and a preparation method and application thereof.The preparation method for the silicon nitride ceramic slurry provided by the invention comprises the following steps: step one, heating silicon nitride powder, to obtain thermal-oxidized silicon nitride powder; step two, mixing the thermal-oxidized silicon nitride powder and a sintering aid, and drying, to obtain dry powder; step three, enabling the dry powder to mix with a resin, a dispersing agent, a defoaming agent and a photoinitiator, to obtain the silicon nitride ceramic slurry. The advantage of the preparation method is that the surface oxidation treatment cost of the silicon nitridepowder is low, the solid content of the silicon nitride ceramic slurry is apparently improved, a scattering phenomenon of the silicon nitride ceramic slurry in a photocuring forming process is reduced, the needed exposure time of the silicon nitride ceramic slurry in the photocuring forming process is reduced, a forming efficiency is improved, and the thermal-oxidized silicon nitride powder can promote sintering densification and improve ceramic performance.

Owner:GUANGDONG UNIV OF TECH

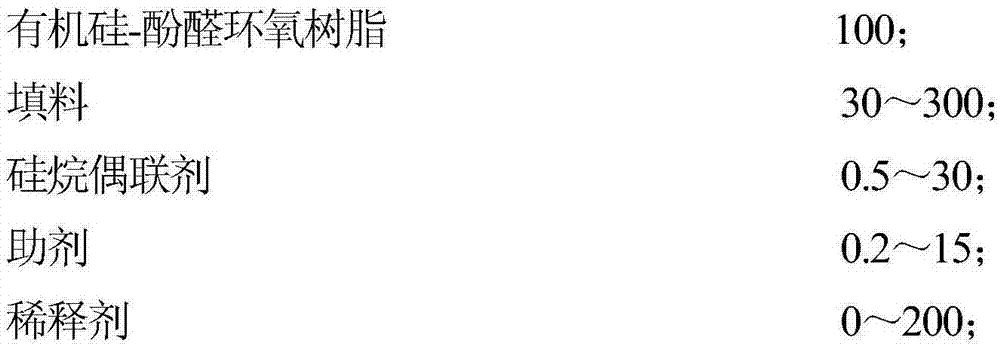

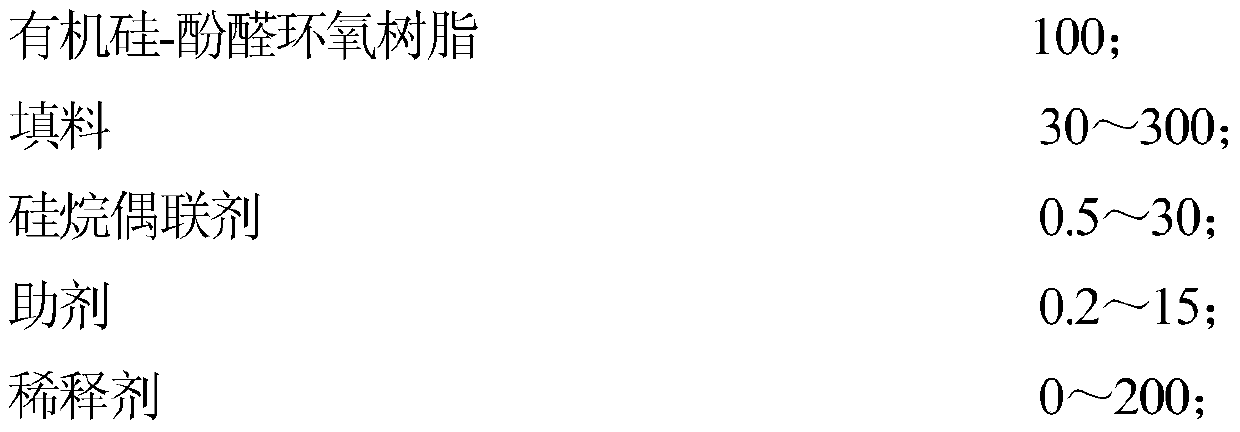

High-temperature ceramic organosilicon-phenolic epoxy anticorrosive paint and preparation method thereof

ActiveCN106893448AEasy constructionRapid ceramicizationAnti-corrosive paintsEpoxy resin coatingsEpoxyWeather resistance

The invention belongs to the technical field of paints, and particularly relates to a high-temperature ceramic organosilicon-phenolic epoxy anticorrosive paint and a preparation method thereof. The paint is characterized in that organosilicon-phenolic epoxy resin is synthesized through a chemical grafting method, and the resin simultaneously has an organosilicon chain segment and a phenolic epoxy chain segment. On the one hand, the resin has the characteristics of heat resistance, weather resistance, wear resistance, flexibility and the like of the organosilicon chain segment, the phenolic epoxy chain segment on the resin molecule has a higher metal base material adhesive force than the organosilicon chain segment, and the corrosion resistance effect after the phenolic epoxy chain segment is crosslinked with a curing agent is higher than that of the organosilicon chain segment, thereby solving the problems of low adhesive force and poor anticorrosive effect of the organosilicon paint; and on the other hand, the carbon residue rate of the phenolic epoxy chain segment in a high-temperature environment is high, and the phenolic epoxy chain segment and a thermal degradation product of the organosilicon chain segment in the high-temperature environment can form secondary film forming action, thereby improving the ceramic effect of a coating in the high-temperature environment.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

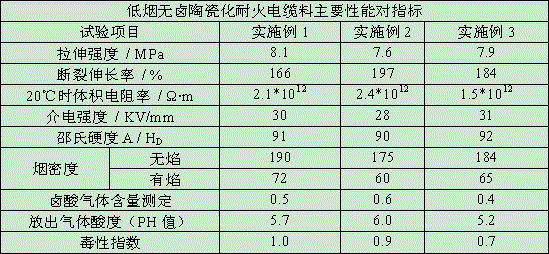

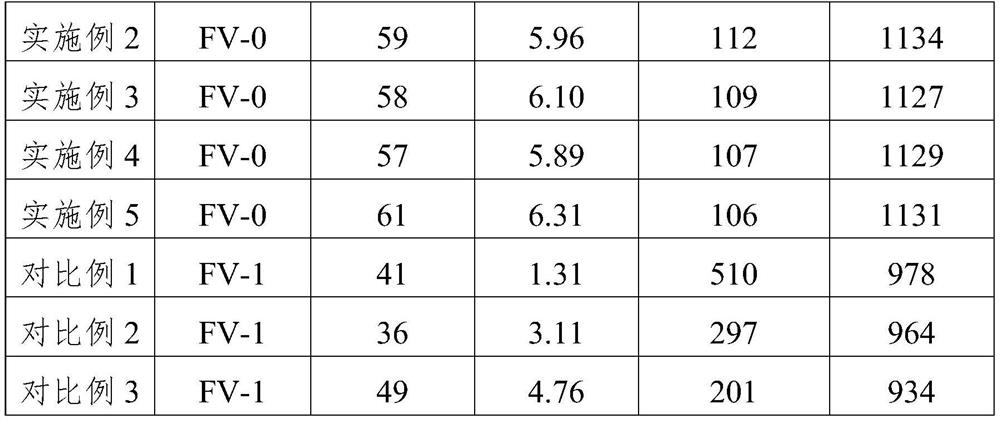

Low-smoke zero-halogen ceramic fireproof cable material and preparation method thereof

InactiveCN105131416ACrust temperature is lowReduced insulation effectPlastic/resin/waxes insulatorsOcteneCarvacryl acetate

The invention relates to a low-smoke zero-halogen ceramic fireproof cable material and a preparation method thereof. The low-smoke zero-halogen ceramic fireproof cable material is prepared from the following materials in parts by weight: an ethylene-vinyl acetate copolymer, an ethylene-alpha-olefin copolymer, maleic anhydride-grafted amorphous polyolefin, mica powder, ceramic powder, glass powder, magnesium hydroxide, calcium oxide, zinc oxide, melamine cyanurate, an antioxidant 1010, a silane coupling agent A-172, and lubricant silicone master batch; the ethylene content of the ethylene-vinyl acetate copolymer is 28-40%, and the melt flow rate is 3-5g / 10min; the ethylene-alpha-olefin copolymer is a mixture of one or two of an ethylene-alpha-propylene copolymer and an ethylene-alpha-octene copolymer which are mixed according to any ratio by weight; the glass powder is low-melting-point glass powder having the melting point of 500-800 DEG C. The low-smoke zero-halogen ceramic fireproof cable material is porcelainized to change into a hard ceramic protection layer after ignition at high temperature and has certain mechanical strength, thereby ensuring normal operation of a wire and cable line.

Owner:中广核三角洲(苏州)高聚物有限公司

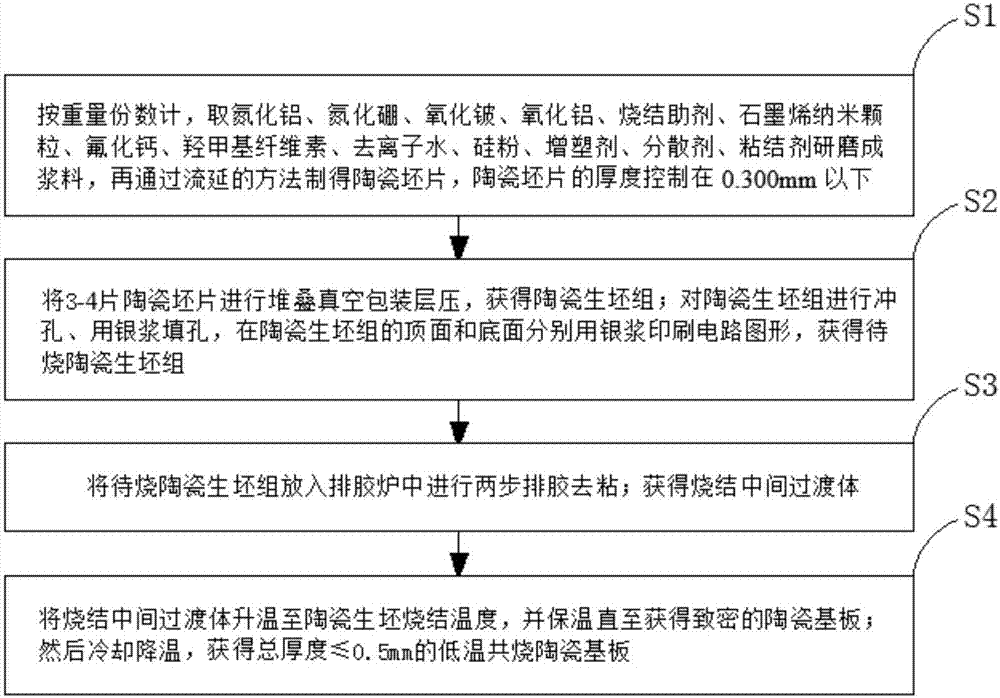

Forming and sintering method of low temperature co-fired ceramic substrate

The invention relates to a forming and sintering method of a low temperature co-fired ceramic substrate; the method comprises the steps of preparing ceramic body sheets; stacking the ceramic block sheets, packaging in vacuum, and laminating to obtain a ceramic green body set; punching the ceramic green body set, filling holes with silver paste and, printing circuit patterns on top and bottom surfaces of the ceramic green body set via silver paste to obtain a ceramic green body set to be fired; placing the ceramic green body set to be fired into a rubber removal furnace and performing two-step rubber removal and gluing to obtain a sintered intermediate transition part; heating the sintered intermediate transition part to ceramic green body sintering temperature, and holding the temperature until a compact ceramic substrate is obtained; cooling to obtain the low temperature co-fired ceramic substrate. Compared with the prior art, the method of the invention has the advantages that the combination of aluminum nitride, boron nitride and beryllium oxide decreases cost and maintains heat-dissipating performance; by adding graphene nanoparticles, heat can be transferred, and compactness of the ceramic substrate is also improved; the physiochemical prosperities of the ceramic substrate are optimized via hydroxymethyl cellulose.

Owner:FUJIAN HUAQING ELECTRONICS MATERIAL TECH

High-performance silicon nitride ceramic mobile phone rear cover material as well as preparation method and application thereof

The invention belongs to the field of non-oxide ceramic materials and discloses a high-performance silicon nitride ceramic mobile phone rear cover material as well as a preparation method and application thereof. The preparation method disclosed by the invention comprises the following steps: mixing and drying Si3N4 and MgO-Re2O3 to obtain powder A; performing the same mixing process on the pure Si3N4 powder, drying to obtain the powder B, sequentially filling the powder A and the powder B into a sintering furnace, and preparing the high-performance Si3N4 ceramic gradient material which is hard in surface and tough in interior in a nitrogen atmosphere, wherein the nitrogen pressure is a negative pressure. The relative density of the prepared Si3N4 ceramics is higher than 95%, the surface hardness is 18-30GPa, the breaking tenacity of the inner layer is 10-20MPa.m<1 / 2>, and the overall bending strength is 1200-1500MPa. According to the method disclosed by the invention, preparation of the high-performance Si3N4 gradient ceramics is realized. Finally, the high-performance silicon nitride ceramic mobile phone rear cover product is prepared by cutting, coarse grinding, accurate grinding and polishing.

Owner:GUANGDONG UNIV OF TECH

Low temperature co-fired ceramic powder and special raw material and use thereof

The present invention relates to a ceramic powder and special raw material and use thereof. The raw material of the ceramic powder comprises 20-80 mass parts of SiO2, 10-50 mass parts of AlF3 and 0-30 mass parts of regulator. The raw material for preparing the ceramic powder is mixed and crushed, followed by melted into liquid glass at 1200-1400° C., quenched to obtain the ceramic powder. The low temperature co-fired ceramic powder has the following advantages: low sintering temperature (750-850° C.) and controllable sintering shrinkage rate; the dielectric constant of the ceramic block prepared with the ceramic powder is adjustable between 4.5 and 10 (1 MHz), the dielectric loss is less than 0.002, the mechanical strength is high and the preparation process is simple. The ceramic powder may be used for electric devices such as ceramic substrate, resonator, etc. as well as in other microelectronic packaging.

Owner:TSINGHUA UNIV

High-strength flame-retardant cable special material and preparation method thereof

PendingCN112679961AFacilitate the melting processCompact structureDecabromodiphenyl etherAluminium hydroxide

The invention provides a high-strength flame-retardant cable special material and a preparation method thereof, and relates to the technical field of cable special materials. The cable special material comprises the following raw materials in parts by weight: 100-120 parts of methyl vinyl silicone rubber, 1-5 parts of boron oxide, 15-20 parts of a reinforcing filler, 20-30 parts of low-melting-point glass powder, 15-20 parts of magnesium hydroxide, 5-10 parts of aluminum hydroxide, 1-5 parts of a modified flame retardant, 5-8 parts of a structure control agent, 3-5 parts of a vulcanizing agent and 15-20 parts of decabromodiphenyl ether. The prepared high-strength flame-retardant cable special material effectively reduces the ceramization temperature of a silicone rubber fireproof composite material, improves the ceramization conversion rate and the ceramization strength, has excellent flame retardancy and high resistivity, can meet the requirements of the industry, and has a good application prospect.

Owner:SICHUAN PROVINCE JINLU RESIN

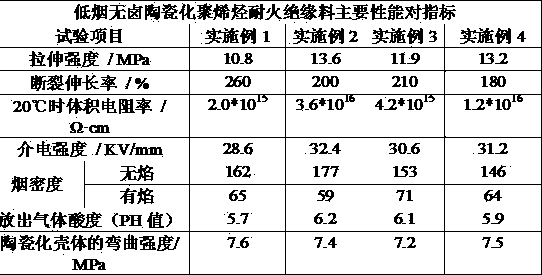

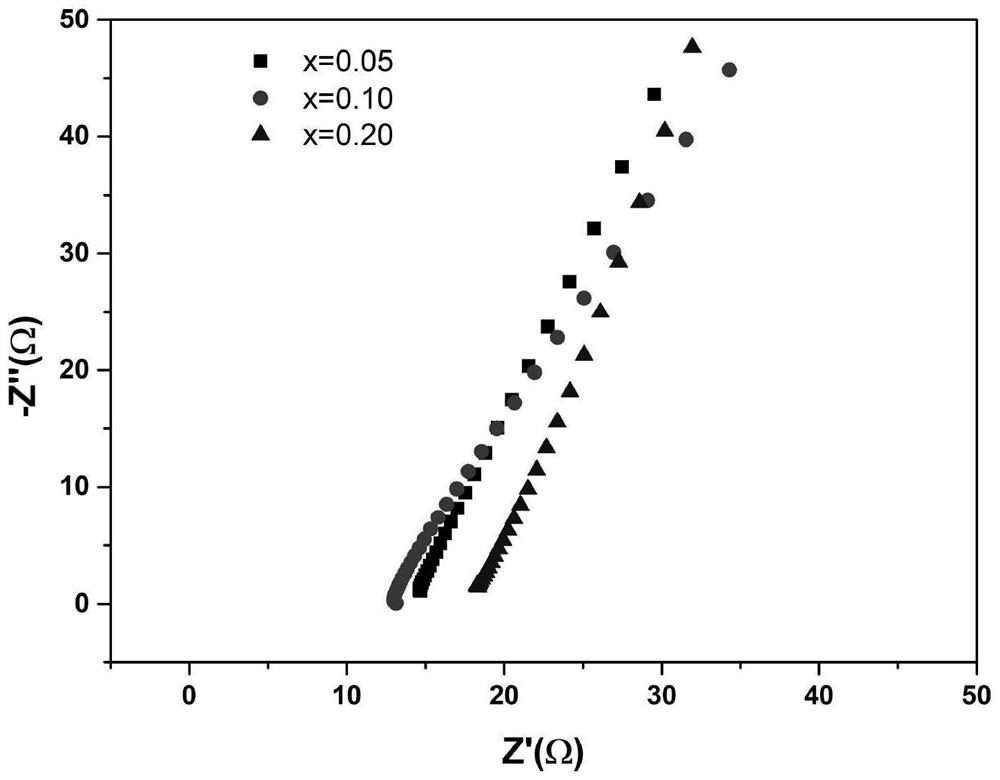

Preparation technology of low-smoke and halogen-free ceramic polyolefin refractory insulation material

InactiveCN109971064AImprove bending strengthHard crustPlastic/resin/waxes insulatorsAntioxidantBoron carbide

The invention discloses a preparation technology of a low-smoke and halogen-free ceramic polyolefin refractory insulation material. The technology includes the steps of: 1. putting metallocene polyethylene, an ethylene-alpha-octene copolymer, high density polyethylene resin, maleic anhydride grafted amorphous polyolefin, pentaerythritol, boron carbide, silicon carbide, nano-aluminum hydroxide, brucite, talcum powder, an antioxidant, a silane coupling agent, sodium dodecylbenzene sulfonate and lubricant silicone masterbatch all into an internal mixer at one time for mixing, and performing discharging when the temperature of the mixed materials reaches 140-145DEG C; and 2. sending the material obtained in step 1 into a tapered feeding hopper, and conducting plasticizing extrusion by a twin-screw extrusion set. The polyolefin refractory insulation material obtained by the technology provided by the invention has good ceramic performance, the sintered ceramic shell has high bending strength, the crust is very hard and dense, no secondary fire is caused, and the refractory insulation material can be fired into a hard ceramic armor to reach very good heat insulation, cooling and refractory effects, has low smoke during combustion, is halogen-free, non-toxic and odorless, and passes the ROHS inspection standards.

Owner:中广核高新核材科技(苏州)有限公司

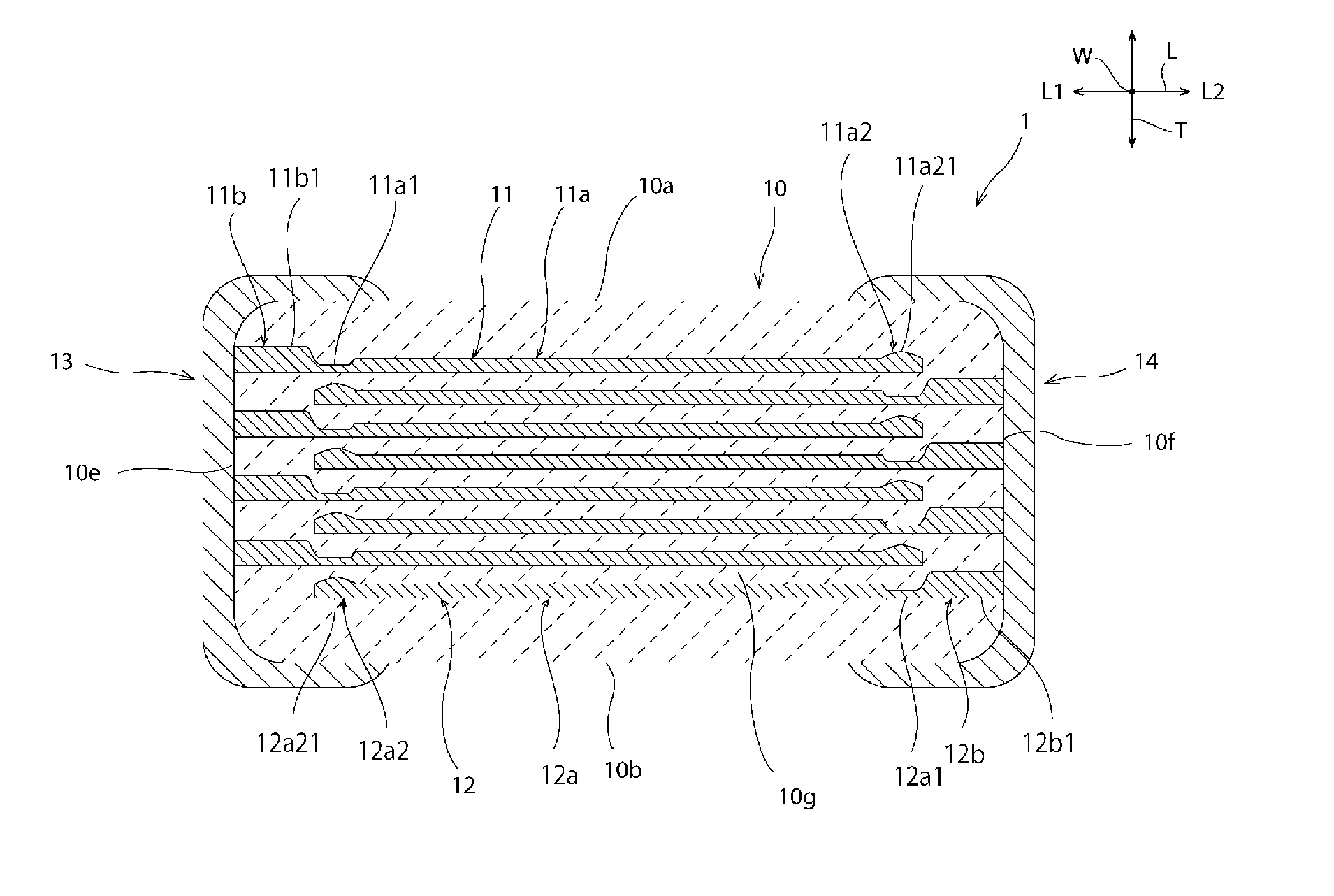

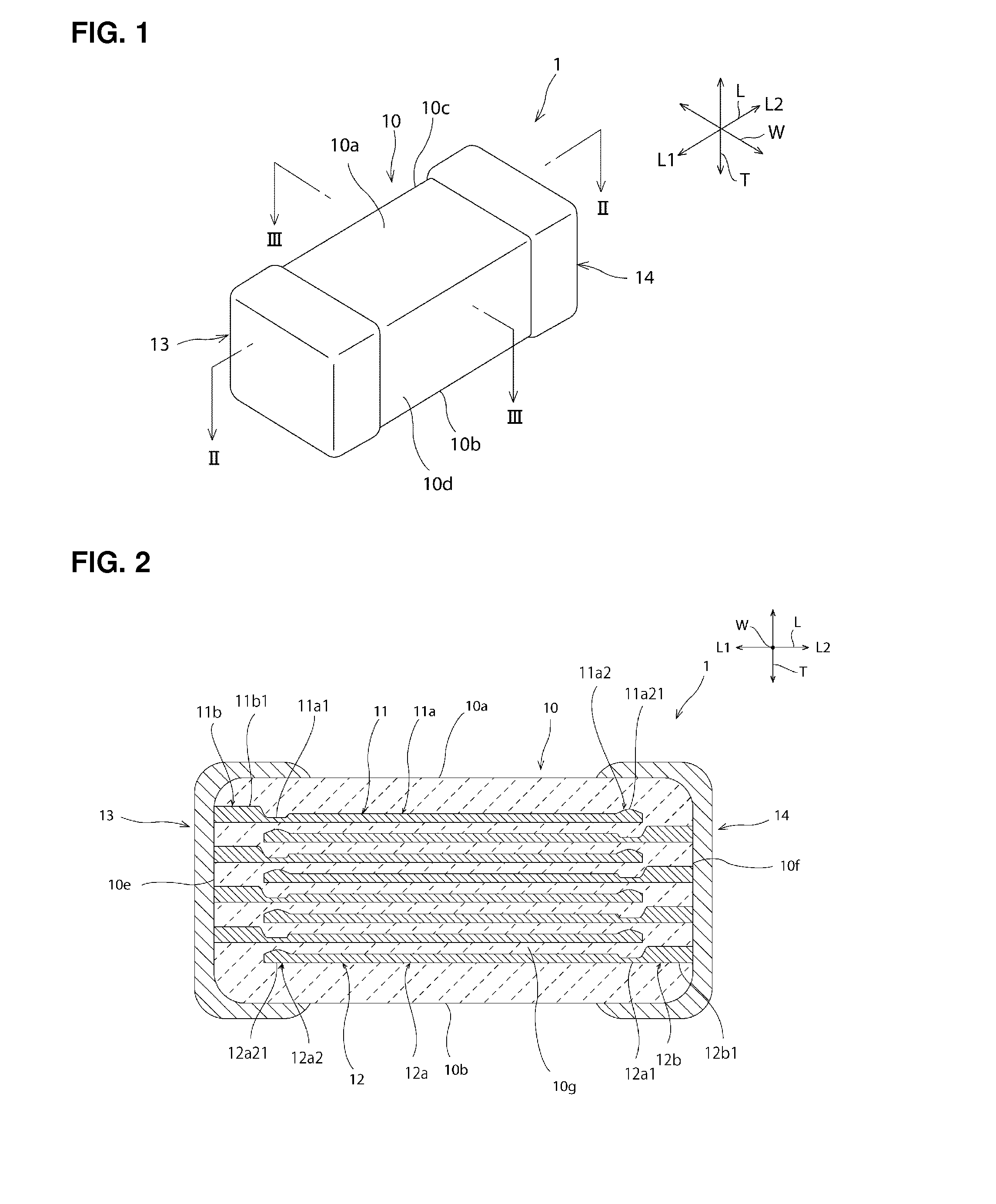

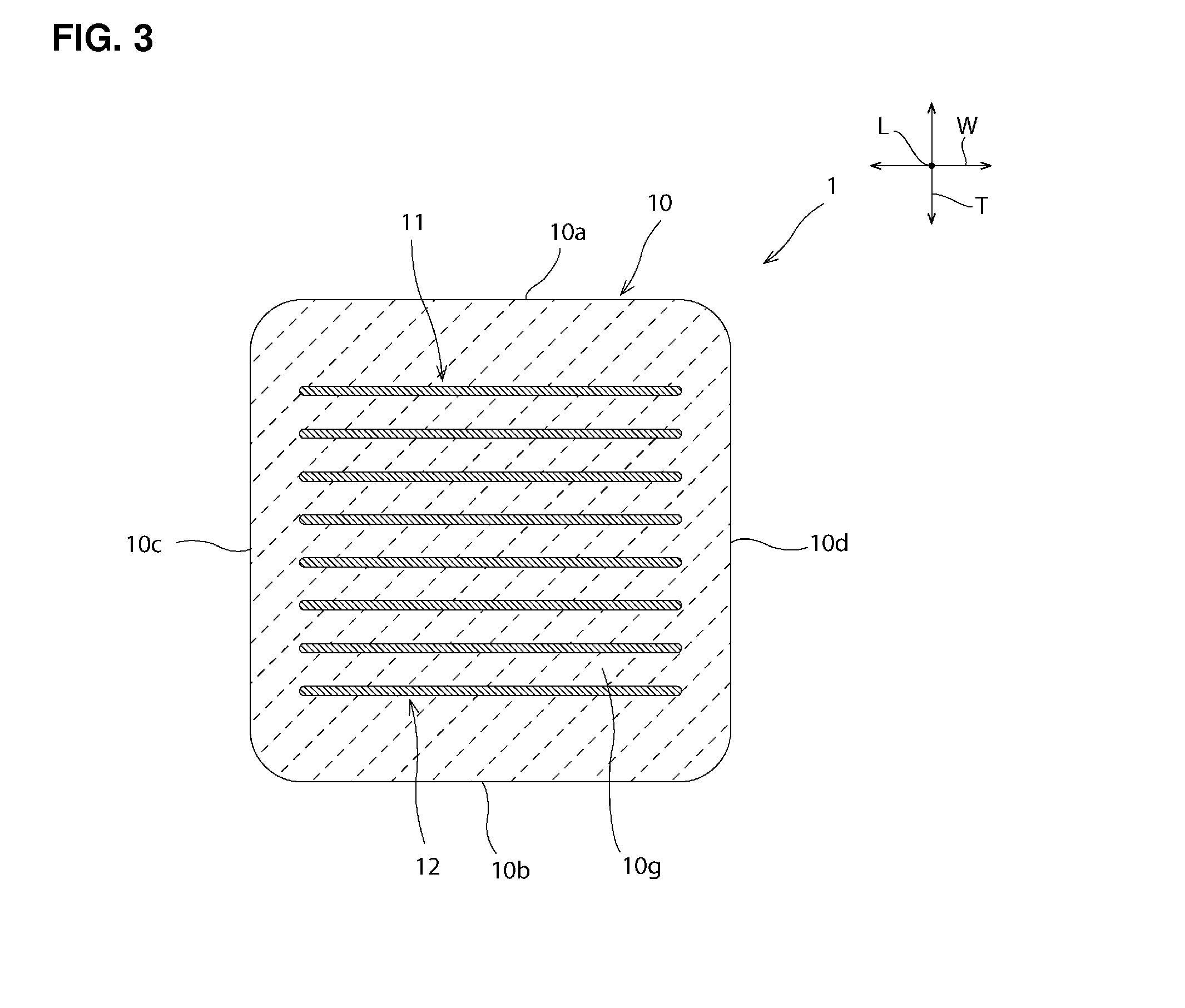

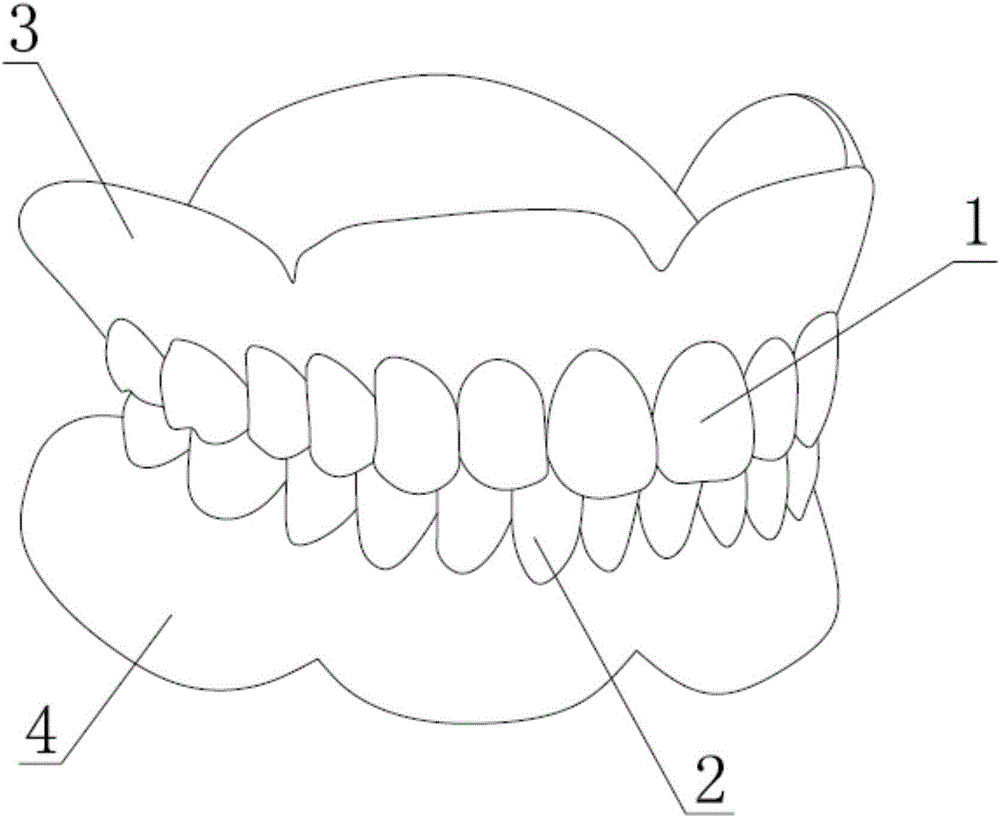

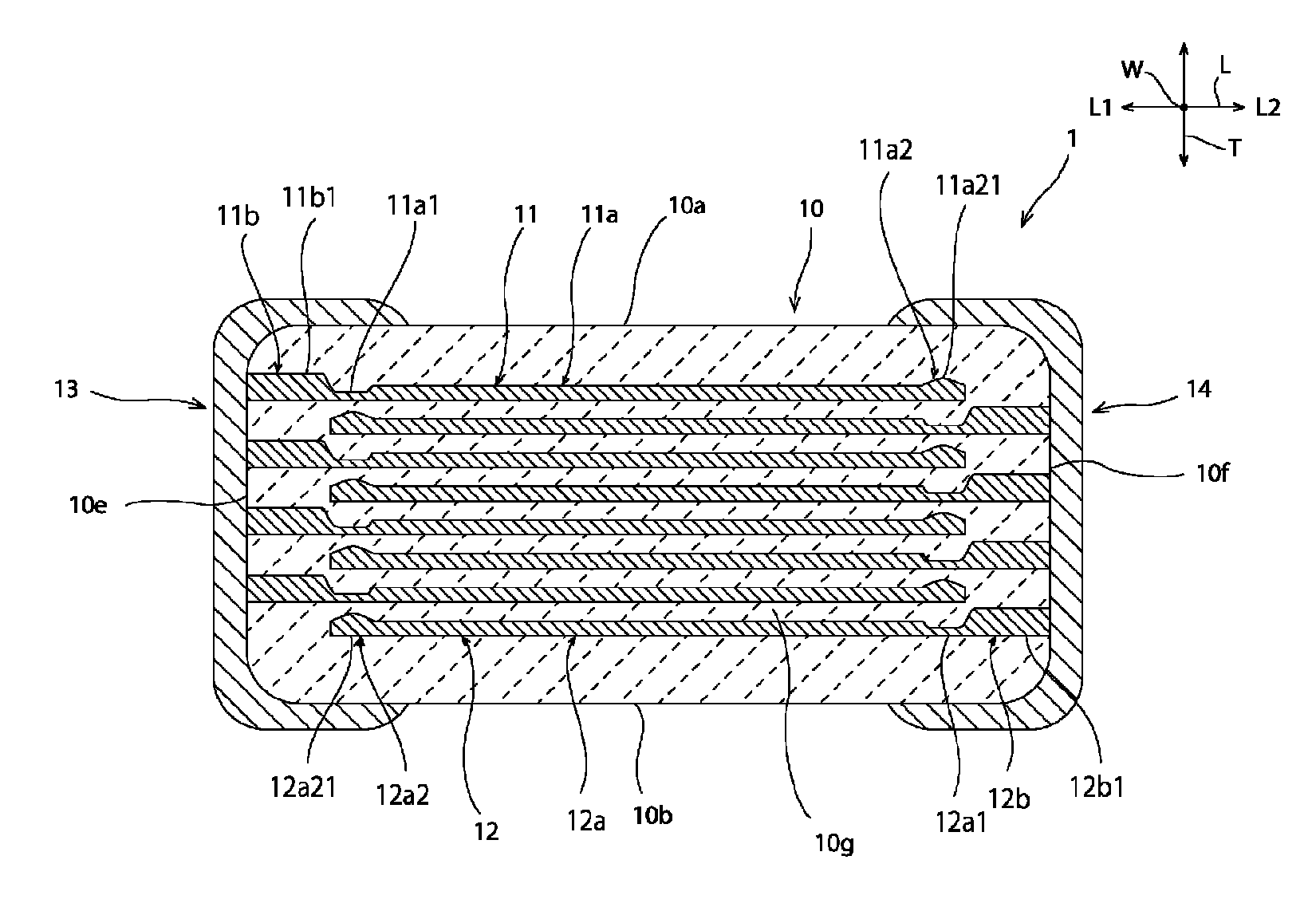

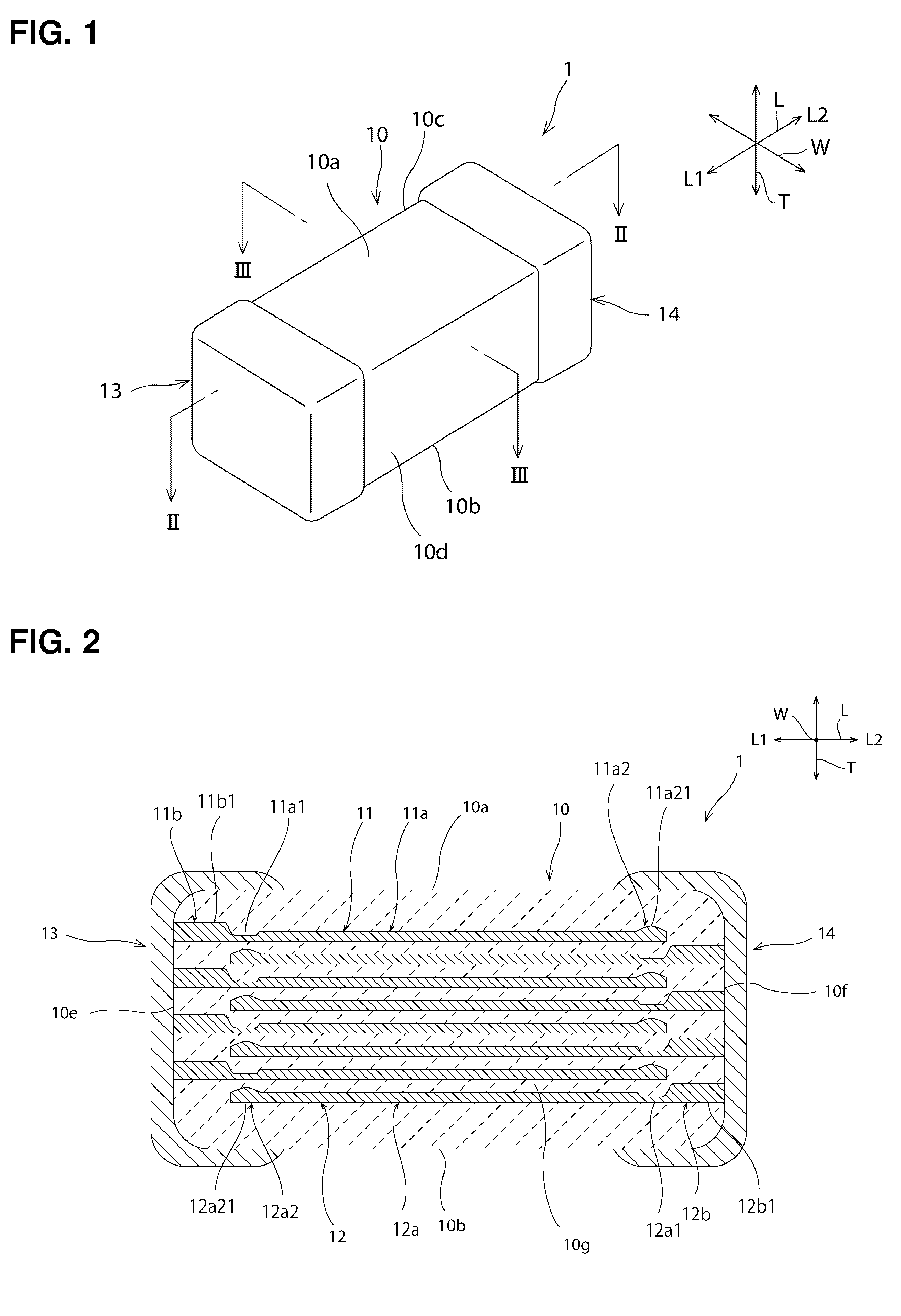

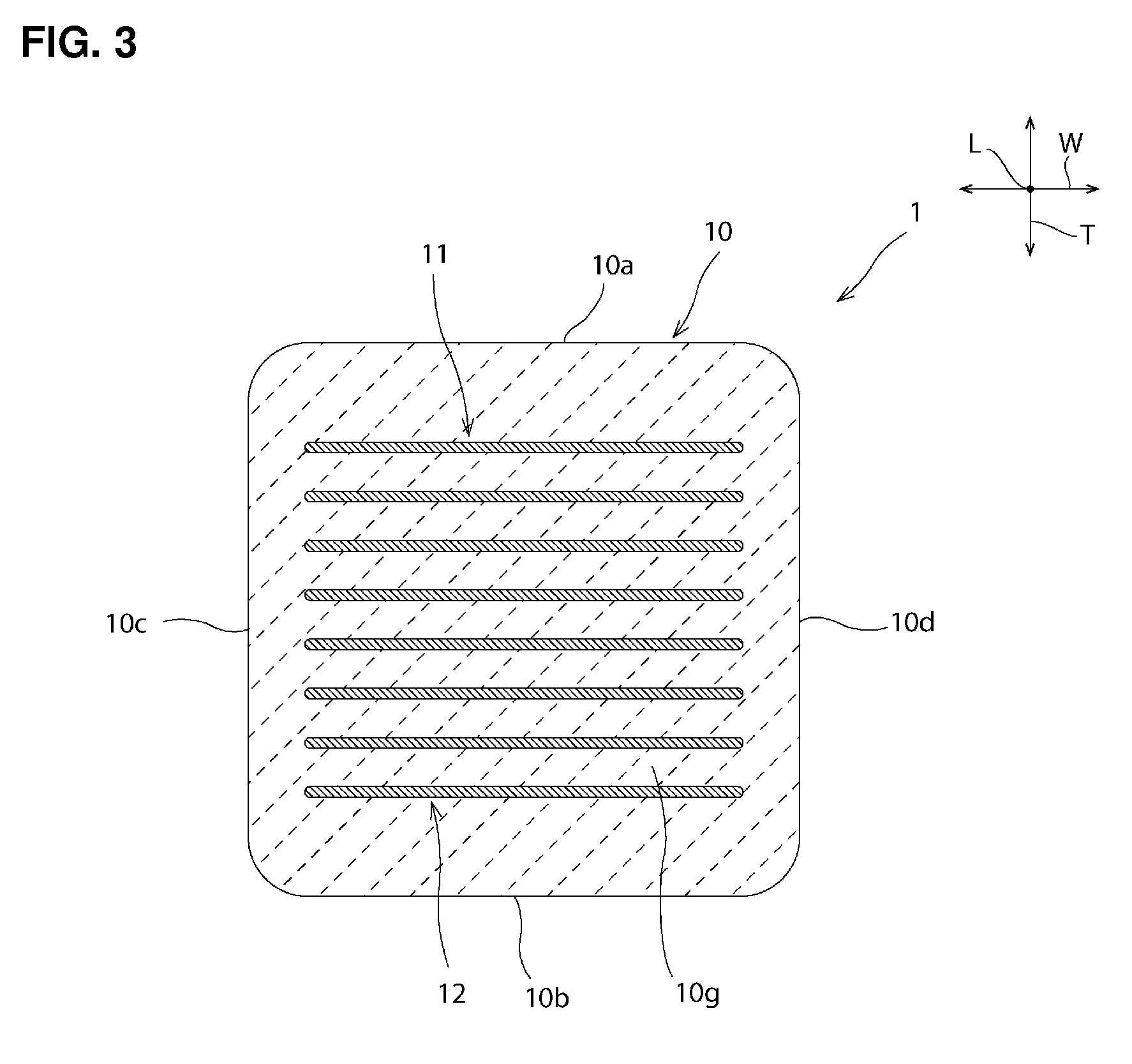

Ceramic electronic component

ActiveUS20130279070A1Enhanced ceramic performanceImprove performanceFixed capacitor electrodesStacked capacitorsElectronic componentMaterials science

A ceramic electronic component includes a first internal electrode that includes a first opposed section and a first extraction section. The first opposed section is opposed to a second internal electrode with a ceramic layer interposed therebetween. The first extraction section is located closer to a first end surface than the first opposed section. The first extraction section includes a first thick section. The first thick section is thicker than a first central section of the first opposed section. The first opposed section includes a first base end section opposed to a second tip section of the second internal electrode closer to the first end surface, with the ceramic layer interposed therebetween, and the first base end section includes a first thin section. The first thin section is thinner than the first central section.

Owner:MURATA MFG CO LTD

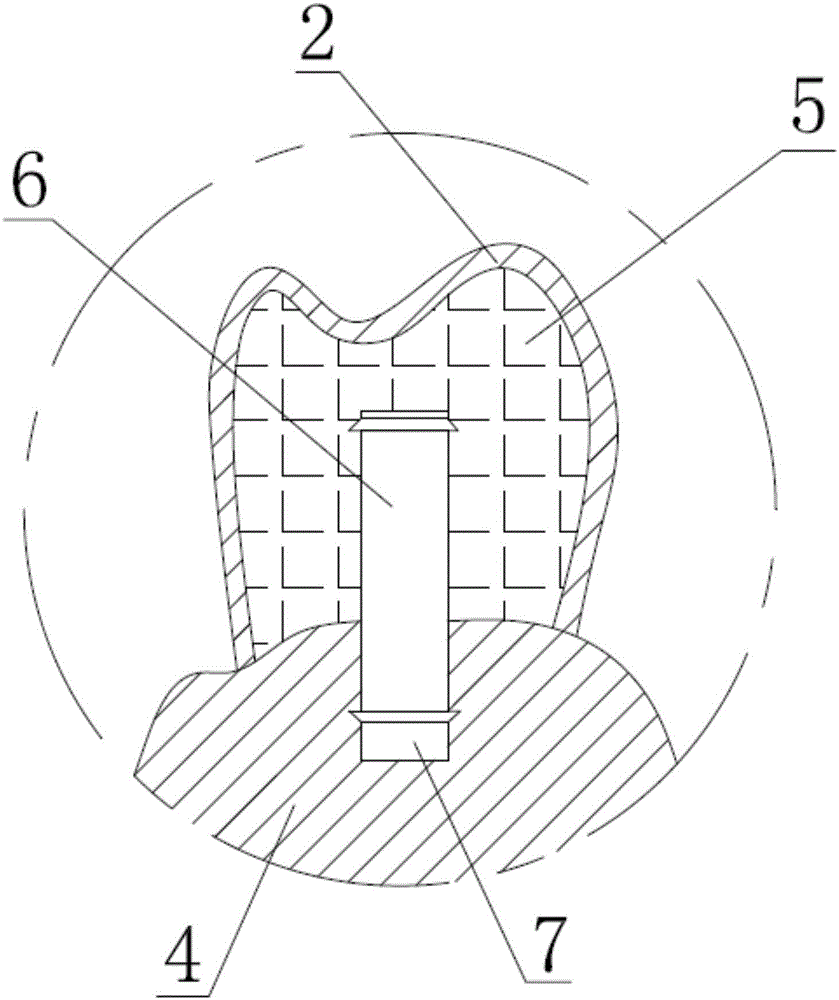

Detachable denture and preparation method thereof

InactiveCN106510875AImprove the level of rowing teethLow costDental implantsArtificial teethDenturesDental Base

The present invention relates to the field of a denture, and especially relates to a detachable denture and a preparation method thereof. The denture comprises a mounting unit, also includes an upper dental crown, a lower dental crown, an upper dental base and a lower dental base which are formed by 3D printing, the upper dental crown and the lower dental crown are filled with filling bodies, the mounting unit comprises an implant abutment and an abutment yoke body, the implant abutment is fixed in the upper dental crown and the lower dental crown, the abutment yoke body is fixed in the dental base and the lower dental base, the implant abutment and the abutment yoke body are in magnetic connection, and connection gaps between the upper dental crown and the upper dental base and between the lower dental crown and the lower dental base are filled with paste. The upper dental crown and the lower dental crown are overall structures comprising a plurality of dental crowns, the upper dental crown and the lower dental crown are printed directly by 3D printing technology after tooth-arrangement design by use of a computer, the integrity is good, the upper dental crown and the lower dental crown are not easy to deform and misplace, by the tooth-arrangement design by use of the computer, the tooth-arrangement level of a technician can be improved maximally, a lot of work steps are saved, and cost is saved for patients.

Owner:东莞市永嘉义齿有限公司

Titanium nitride ceramic substrate for LED

The invention discloses a titanium nitride ceramic substrate for an LED. According to the titanium nitride ceramic substrate, various raw materials in the LTCC preparation process are optimized, titanium nitride is used as the main raw material, aluminum nitride, aluminum oxide, yttrium oxide and natural zeolite are added in a supplementary mode and used as the main raw materials, addition agents such as glass sintering aids, copper nanometer particles, solvent, plasticizer, dispersing agents, bonding agents and toughened fibers are added, and then the physical and chemical performance of the ceramic substrate is optimized. The thermal conductivity of the ceramic substrate is larger than 800W / (m.k), bending strength is larger than 400 MPa, and the dielectric constant is smaller than 2; meanwhile, by means of a conventional LTCC preparing method, the main raw materials and the addition agents can be prepared into the ceramic substrate with the high conductivity, and the preparation process is simple and beneficial for industrialization.

Owner:长沙鼎成新材料科技有限公司

High-temperature-resistant and graphene-oxidation-resistant nano-ceramic coating and preparation method thereof

PendingCN110835477AEnhanced ceramic performancePrevent oxidationFireproof paintsCeramic coatingNanoceramic

The invention discloses a high-temperature-resistant and graphene-oxidation-resistant nano-ceramic coating. The inner layer of the coating is mainly composed of graphene, nano-alumina powder and nanometer silicon oxide powder, and the graphene, the nano-alumina powder and nanometer silicon oxide powder are combined through silica sol; and the outer layer of the coating is a transparent silica protective film formed by ceramic resin at a high temperature. The inner layer is prepared from the graphene, the nano-alumina powder and the nanometer titanium oxide powder in proportion, so the performances of the ceramic can be improved by utilizing the high heat conduction and far infrared functions of the graphene. The outer layer structure is adopted, so graphene oxidation can be avoided, and the far infrared function of the inner layer is not disturbed. The ceramic coating can be applied to radiators with high temperature and medium-low temperature of 800 DEG C or below, has resistance to high temperature and has high thermal conductivity and the far-infrared function. The heat superconducting performance of graphene makes the heat conductivity of the coating after implementation reach50-80 W / M.k and the infrared emissivity reach 0.9 or above. The selected nano-alumina powder and nanometer silicon oxide powder are beneficial to improving the infrared emissivity of the coating.

Owner:河南洛烯纳米材料有限公司

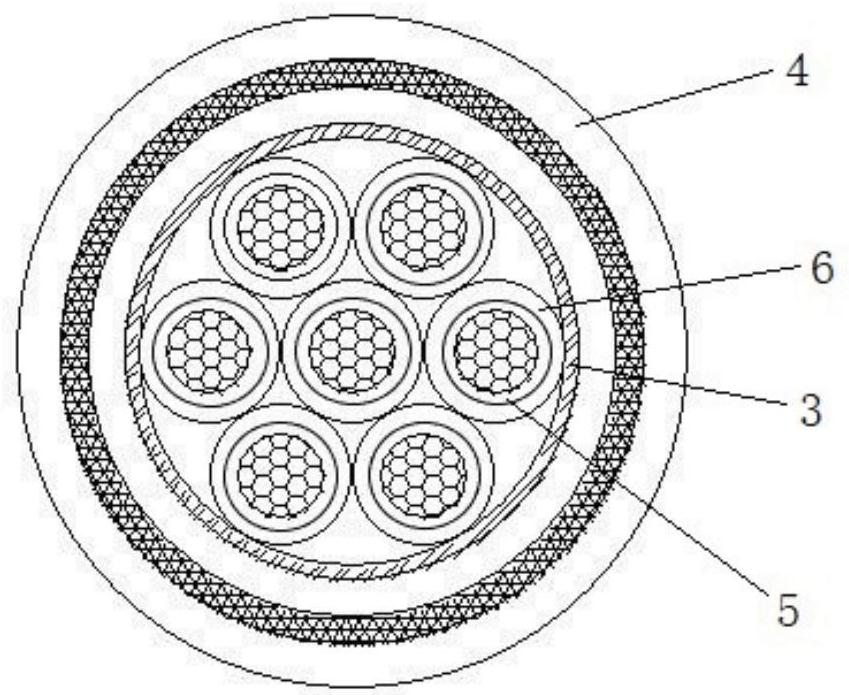

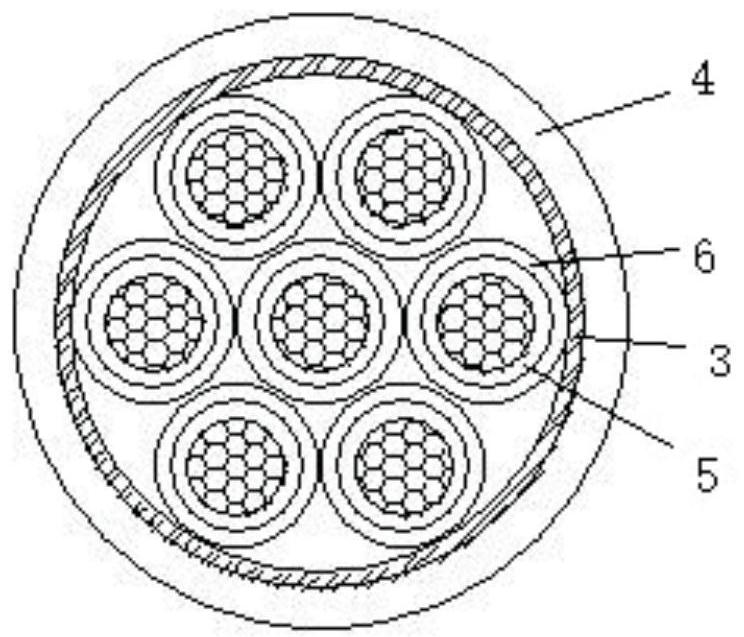

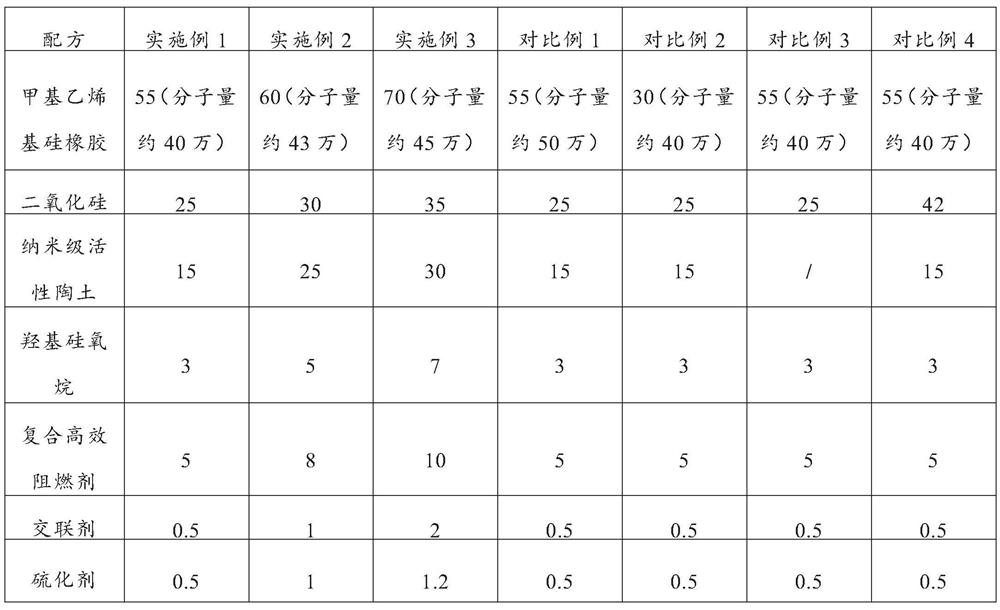

Tensile flame-retardant silicone rubber composition, flame-retardant B1-level silicone rubber insulation polyolefin sheath control cable and preparation method thereof

ActiveCN113652091AHigh strengthEnhanced tensile tear strengthPlastic/resin/waxes insulatorsClimate change adaptationPolymer sciencePolyolefin

The invention provides a tensile flame-retardant silicone rubber composition, a flame-retardant B1-grade silicone rubber insulation polyolefin sheath control cable and a preparation method thereof. The tensile flame-retardant silicone rubber composition comprises the following components by weight: 45-75 parts of methyl vinyl silicone rubber; 20-40 parts of silicon dioxide; 10-35 parts of nano-scale active pottery clay; 3-10 parts of hydroxyl siloxane; 5-10 parts of a composite efficient flame retardant; 0.5-3 parts of a cross-linking agent; and 0.5-2 parts of a vulcanizing agent. The tensile flame-retardant silicone rubber composition has the advantages of high temperature resistance, favorable ceramic forming property, B1-level flame retardancy, overload incombustibility, fire resistance and no toxicity.

Owner:GUANGZHOU METRO DESIGN & RES INST +1

Ceramic-effect-imitating stoving varnish coating for glass wine bottles

InactiveCN113698833AImprove alcohol resistanceEnhanced ceramic performanceAnti-corrosive paintsDefoaming AgentsCeramic

The invention discloses a stoving varnish coating with a ceramic-imitating effect for a glass wine bottle, and relates to the field of coatings. The stoving varnish coating with the ceramic-imitating effect for the glass wine bottle is a double-component stoving varnish coating and comprises the following raw materials in parts: a component A: 30-40 parts of modified silica sol, 25-35 parts of a water-based acrylic dispersion, 0.2-0.3 part of a defoaming agent, 0.1 part of fumed silica, 0.2 part of an anti-sagging auxiliary agent, 1.2-2 parts of a dispersing agent, 0.3-0.5 part of a neutralizing agent, 7-8 parts of amino resin, 6-8 parts of titanium dioxide, 3-4 parts of ceramic micro powder, 8-12 parts of a cosolvent and 26-32 parts of deionized water. According to the stoving varnish coating with the ceramic-like effect for the glass wine bottle, the appearance and touch feeling of a glass stoving varnish coating film can be consistent with the ceramic effect, so that the acceptance degree of consumers is increased; in addition, a glassware is arranged inside, the sealing degree of the glassware and the safety of wine products can be guaranteed after wine is contained; meanwhile, the prepared coating is good in stability and the alcohol resistance after baking is excellent.

Owner:广汉市科思诺新材料科技有限公司

A kind of high-temperature ceramic silicone-phenolic epoxy anticorrosion coating and preparation method thereof

ActiveCN106893448BEasy constructionRapid ceramicizationAnti-corrosive paintsEpoxy resin coatingsEpoxyWeather resistance

The invention belongs to the technical field of paints, and particularly relates to a high-temperature ceramic organosilicon-phenolic epoxy anticorrosive paint and a preparation method thereof. The paint is characterized in that organosilicon-phenolic epoxy resin is synthesized through a chemical grafting method, and the resin simultaneously has an organosilicon chain segment and a phenolic epoxy chain segment. On the one hand, the resin has the characteristics of heat resistance, weather resistance, wear resistance, flexibility and the like of the organosilicon chain segment, the phenolic epoxy chain segment on the resin molecule has a higher metal base material adhesive force than the organosilicon chain segment, and the corrosion resistance effect after the phenolic epoxy chain segment is crosslinked with a curing agent is higher than that of the organosilicon chain segment, thereby solving the problems of low adhesive force and poor anticorrosive effect of the organosilicon paint; and on the other hand, the carbon residue rate of the phenolic epoxy chain segment in a high-temperature environment is high, and the phenolic epoxy chain segment and a thermal degradation product of the organosilicon chain segment in the high-temperature environment can form secondary film forming action, thereby improving the ceramic effect of a coating in the high-temperature environment.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Low-smoke halogen-free ceramic polyolefin refractory insulation material

The invention discloses a low-smoke halogen-free ceramic polyolefin refractory insulation material, which is characterized by comprising the following components by weight: 30-50 parts of metallocenepolyethylene, 30-50 parts of an ethylene-alpha-octene copolymer, 10-20 parts of high density polyethylene resin, 5-10 parts of maleic anhydride grafted amorphous polyolefin, 10-20 parts of pentaerythritol, 6-13 parts of boron carbide, 16-23 parts of silicon carbide, 60-80 parts of nano-aluminum hydroxide, 20-30 parts of brucite, talcum powder, an antioxidant, a silane coupling agent, sodium dodecylbenzene sulfonate, and lubricant silicone masterbatch. The metallocene polyethylene has a tensile strength of greater than or equal to 15MPa and elongation at break of greater than or equal to 500%.The ethylene-alpha-octene copolymer has a melt flow rate of 1-5 g / 10min. The low-smoke halogen-free ceramic polyolefin refractory insulation material provided by the invention can transform into a hard ceramic protective layer after encountering high temperature ignition, and also has certain mechanical strength, thus ensuring the normal operation of wire and cable lines.

Owner:中广核高新核材科技(苏州)有限公司

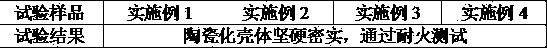

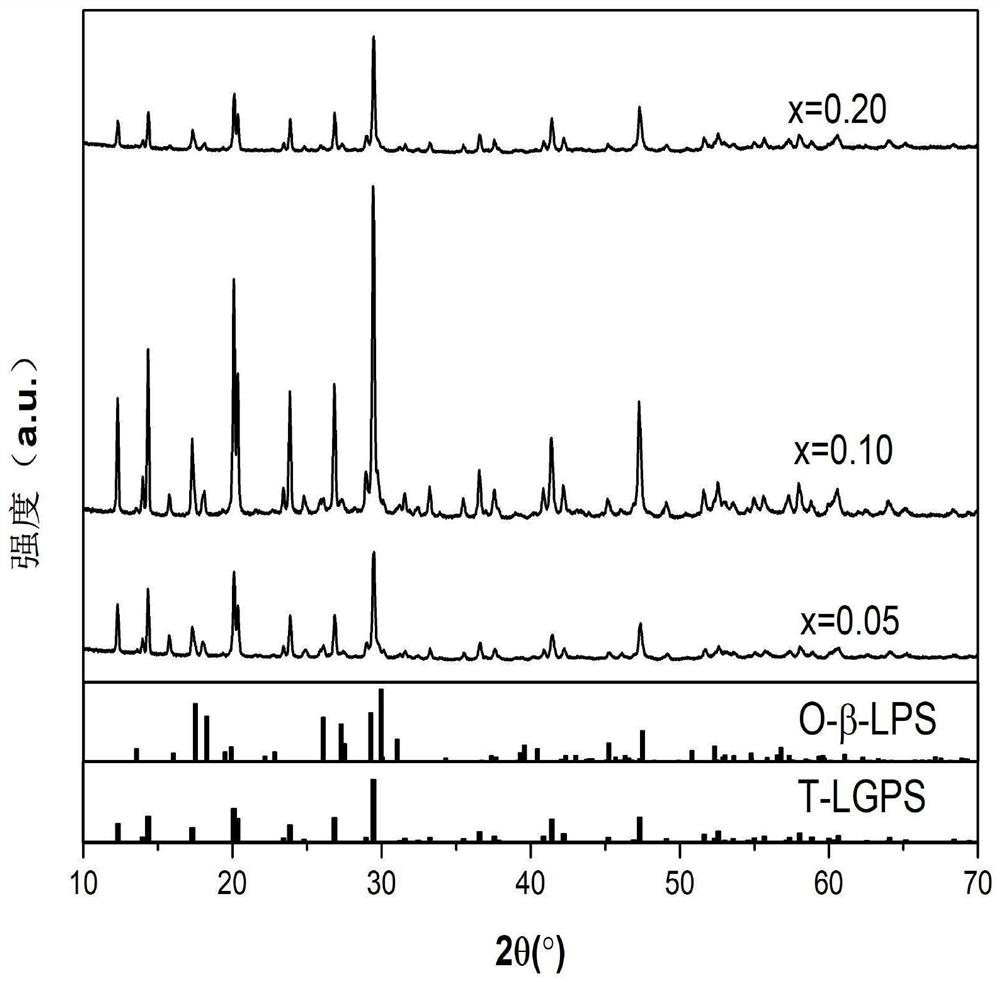

Al<3+> doped and modified LGPS type lithium ion solid electrolyte and preparation method thereof

ActiveCN113823830AExcellent conductivity performanceMeet application needsFinal product manufactureElectrolyte accumulators manufactureCompression moldingSolid state electrolyte

The invention discloses an Al<3+> doped and modified LGPS type lithium ion solid electrolyte and a preparation method thereof. The general formula of the solid electrolyte is Li10.35Ge1.35-0.75xAlxP1.65S12, wherein x is more than or equal to 0.05 and less than or equal to 0.20 in the general formula. The solid electrolyte is prepared by adopting a traditional solid phase process. The preparation method comprises the working procedures of batching, primary ball milling, compression molding, primary sintering, secondary ball milling, compression molding, secondary sintering, gold plating and the like. According to the Al<3+> doped and modified LGPS type lithium ion solid electrolyte provided by the invention, Al<3+> is doped in the Ge<4+> position in the LGPS structure, so that the LGPS type lithium ion solid electrolyte with excellent room-temperature lithium ion conductivity performance is obtained, and the room-temperature lithium ion conductivity can reach 22.1 mS / cm. The preparation method of the lithium ion solid electrolyte is stable and mature in process, the adopted raw materials are easy to obtain, and the lithium ion solid electrolyte has universality and industrial practicability and is easy to industrialize.

Owner:SICHUAN UNIV

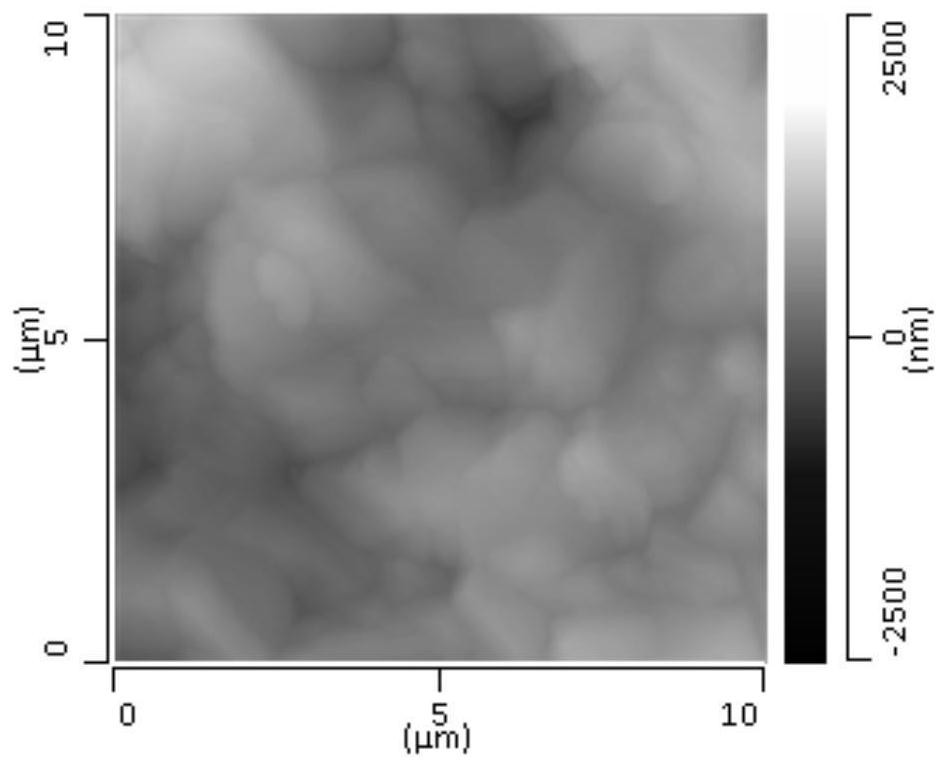

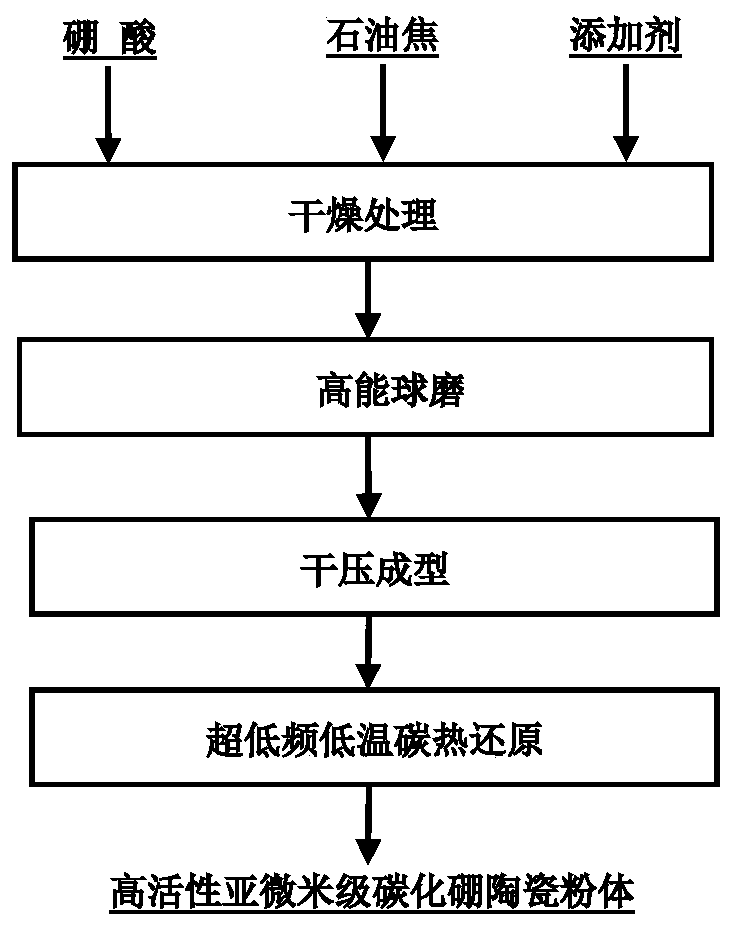

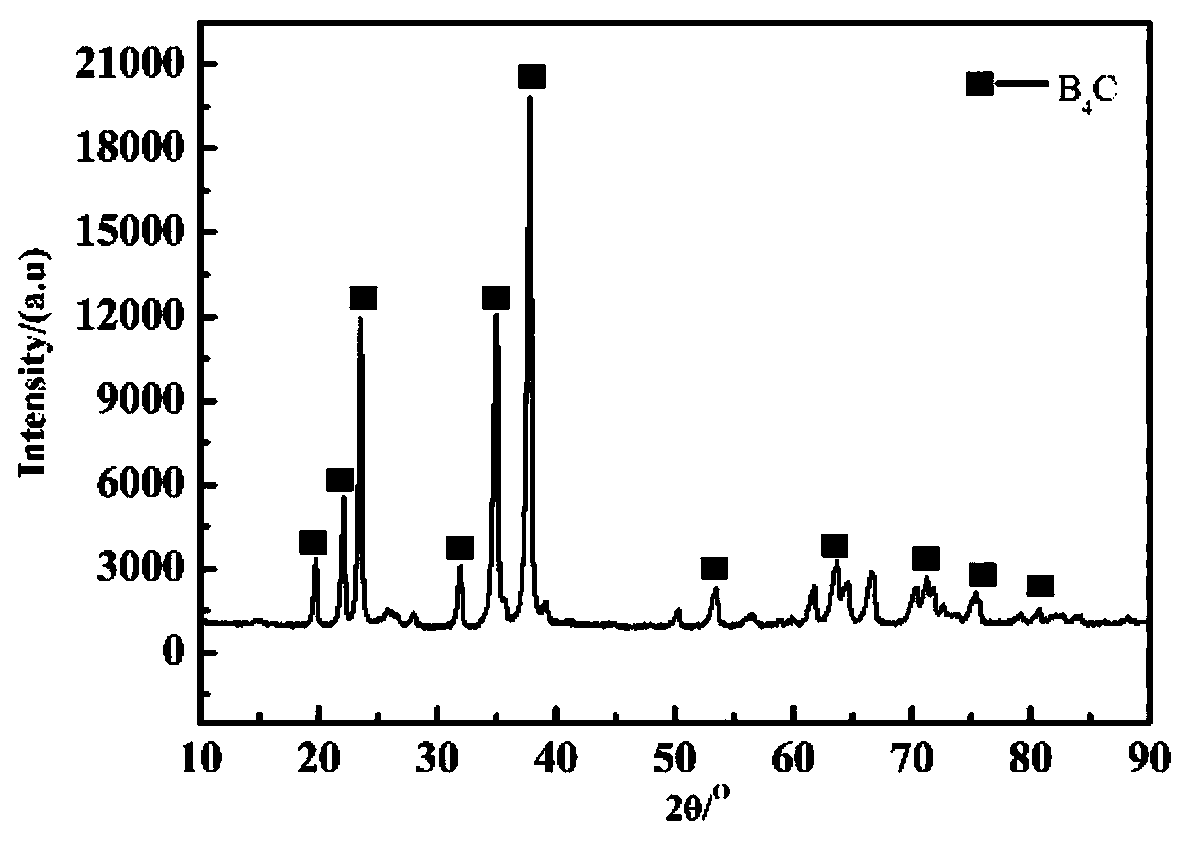

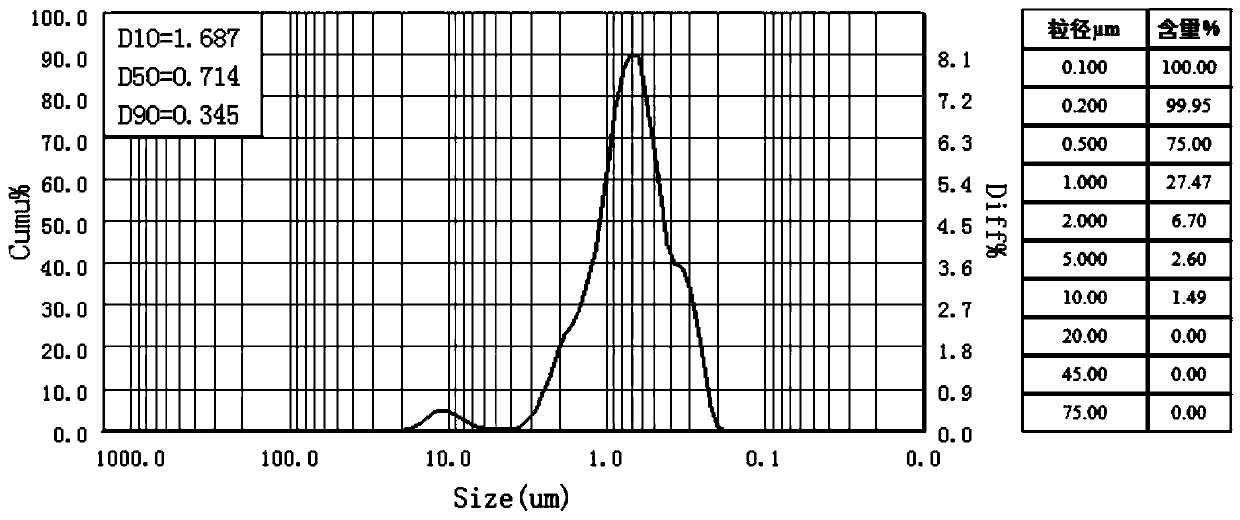

High-activity submicron boron carbide ceramic powder and low-temperature in-situ preparation method thereof

ActiveCN111470868ARaise the reaction temperatureLow reaction temperatureChemical industryCeramic sinteringHeating furnace

The invention provides a high-activity submicron boron carbide ceramic powder and a low-temperature in-situ preparation method thereof, and belongs to the field of preparation of boron carbide powder.The preparation method comprises the following steps: proportioning boric acid, petroleum coke and a rare earth oxide additive, drying, carrying out high-energy ball milling, crushing, and dry-pressmolding, and carrying out low-temperature carbon thermal reduction in an ultralow-frequency heating furnace to in-situ prepare the high-activity submicron boron carbide ceramic powder. According to the method, preparation and crushing are integrated, submicron B4C powder can be directly prepared, and subsequent tedious crushing and purifying are not needed. The rare earth oxide can reduce the carbon thermal reduction temperature, inhibit the growth of B4C grains and prevent the coarsening of grains. Meanwhile, due to the addition of the rare earth oxide, a second phase for promoting subsequentB4C ceramic sintering can be generated through an in-situ reaction, and the sintering activity of the ceramic powder is greatly improved. Compared with the prior art, the method has the advantages oflow reaction temperature, short reaction time, low cost, environment friendliness, energy conservation, consumption reduction and the like, and the process is simple and feasible and can be suitablefor industrial large-scale popularization.

Owner:JIANGSU UNIV

An environment-friendly ablation-resistant ceramic silicone rubber composite material and preparation method thereof

ActiveCN103923465BEnhanced ceramic performanceImprove mechanical propertiesVulcanizationPolymer science

Owner:EAST CHINA UNIV OF SCI & TECH

High-hardness hafnium-based ternary solid solution boride ceramic as well as preparation method and application thereof

The invention belongs to the technical field of ceramic materials, and discloses high-hardness hafnium-based ternary solid solution boride ceramic as well as a preparation method and application thereof. The molecular formula of the boride ceramic is (HfaMe1bMe2c)B2, 0.1< / =a< / =0.9, 0<b<0.9, 0<c<0.9, and a+b+c=1; Me1 and Me2 are Zr, Ta or Ti. The ceramic is prepared by the following steps of adding HfO2, Me1 and Me2 oxides, B4C and carbon powder into a solvent, carrying out ball milling to obtain mixed powder, carrying out die pressing to obtain a blank, putting the blank into a graphite crucible, heating to 1400-1600 DEG C, carrying out heat preservation, and carrying out vacuum heat treatment to obtain hafnium-based ternary solid solution boride powder, and heating the ternary solid solution boride powder to 1000-1400 DEG C by adopting spark plasma sintering, introducing a protective atmosphere, heating to 1900-2100 DEG C, and calcining at the pressure of 10-100 MP to obtain the ternary solid solution boride powder.

Owner:GUANGDONG UNIV OF TECH

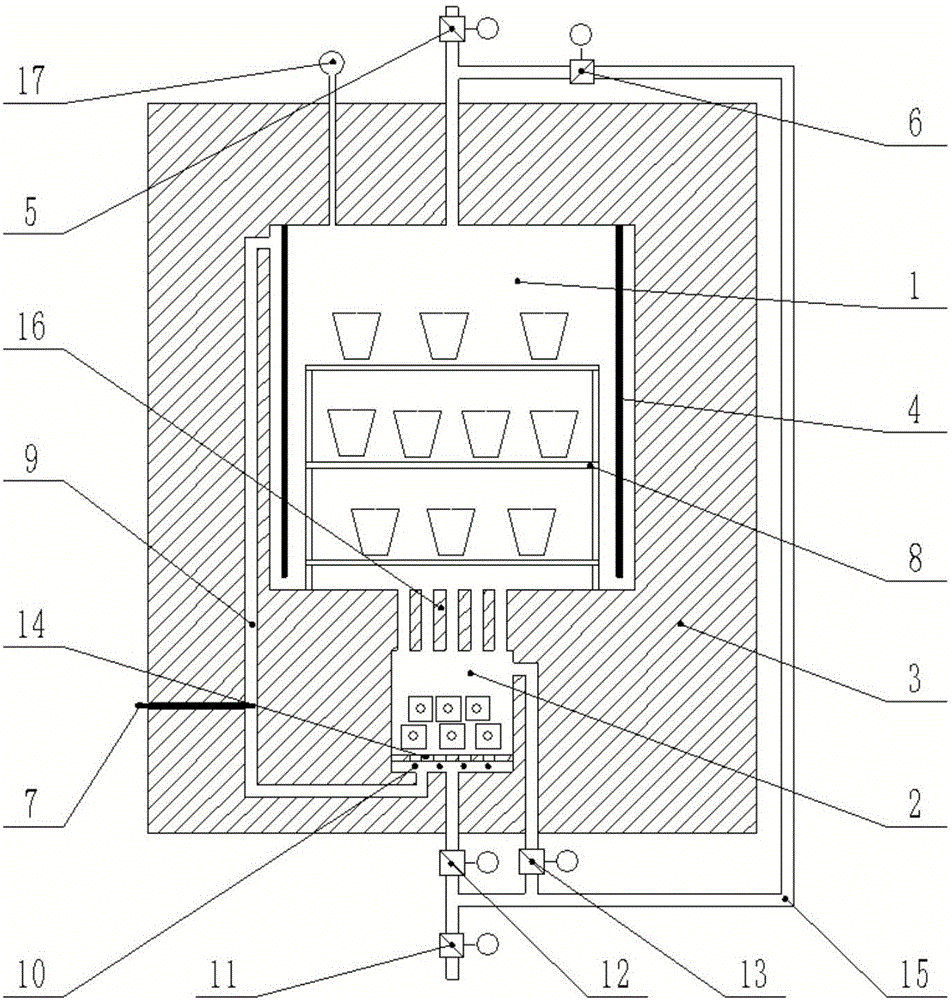

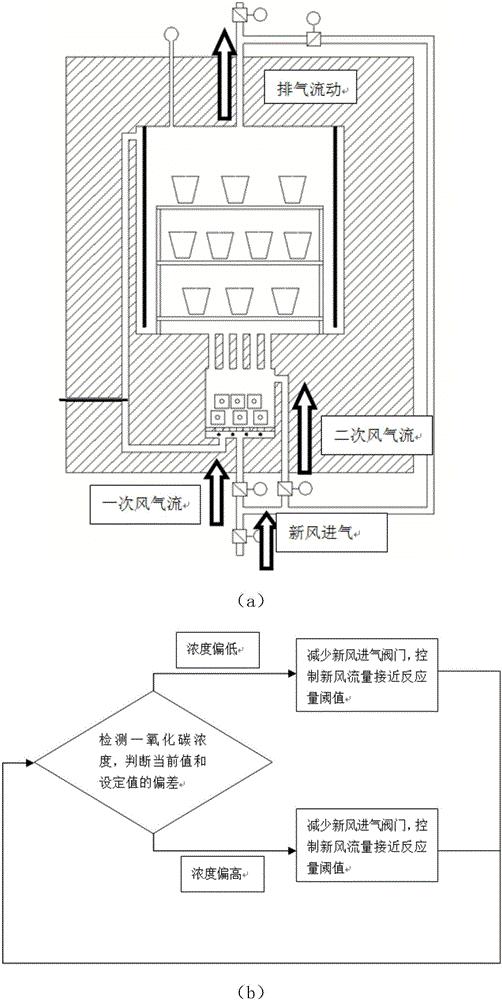

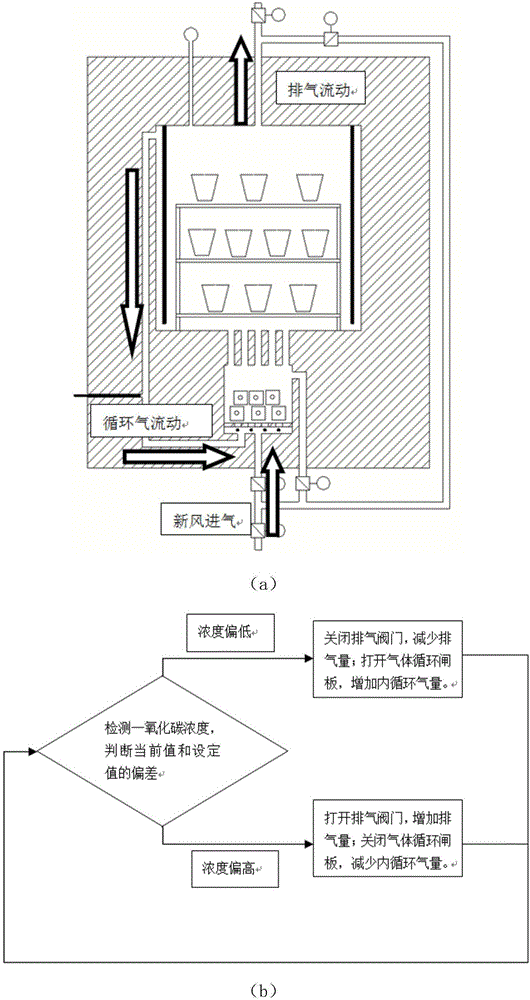

Ceramic firing kiln with controllable firing atmosphere

PendingCN106839757AControl energy lossReduce carbon dioxide and other harmful gas emissionsMuffle furnacesCharge composition/stateEnergy lossCarbon dioxide

The invention relates to a ceramic firing kiln with controllable firing atmosphere, and belongs to the technical field of the ceramic firing. The ceramic firing kiln comprises an air passage between the firing area and the atmosphere control area. The air passage mainly comprises an air passage between the areas, a fresh air inlet passage, an air exhaust passage, an airflow internal circulation passage, an airflow external circulation passage and so on. The ceramic firing kiln with the controllable firing atmosphere is capable of solving the problem that an electrical kiln cannot generate the stable controllable reducing atmosphere internally. Compared with the traditional wood-fired kiln, only a small quantity of the wood charcoal or other carbon component reactants is used for once-firing, the energy loss is controlled, the discharge of a lot of the carbon dioxide or other harmful gases is reduced, the interior of the kiln can reach the higher temperature, the ceramic performance is increased, and the craft art characteristics is improved. Compared with the current common gas kiln in the market, not only the safety is improved, but also the exhaust emission is reduced, the atmosphere generation and the internal temperature control of the kiln are independent mutually, the user operation is simple and convenient, and the rate of the ceramic finished products is greatly improved.

Owner:杭州志在材料科技有限公司 +1

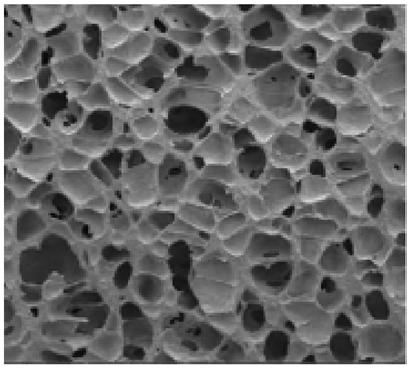

Preparation method of foamed silicone rubber

The invention relates to a preparation method of foamed silicone rubber, and belongs to the field of material preparation. The preparation method is characterized by comprising the following steps of:weighing 100g of rubber compound prepared from methyl vinyl silicone rubber, carrying out mill mixing in a two-roll mixing mill at a room temperature, wrapping rolls with silicone rubber, then adding10-60g of glass fiber powder, a platinum catalyst, 0.2-1.0g of hydrogen-containing silicone oil, and 0-0.8g of hydroxy silicone oil; mixing evenly, and discharging a sheet; and flatly paving, puttingin an aging testing machine for vulcanization, simultaneously foaming, setting the temperature to be 240 DEG C and time to be 5 minutes, and completing the preparation of the foamed silicone rubber.The fire-retardant foamed silicone rubber which can be ceramized at a high temperature is prepared by vulcanization carried out through hydrosilylation reaction and foaming carried out through siliconhydrogen dehydrogenation reaction. After the foamed silicone rubber is fired at the temperature of 1000 DEG C for 30rain, the foamed silicone rubber has good ceramicization effect and hard texture without surface cracks, the cellular structure is kept perfectly, the volume retention rate is above 85%, and the fireproof performance is excellent.

Owner:常馨尹

Ceramic electronic component

ActiveUS9111691B2Improve performanceEnhanced ceramic performanceFixed capacitor electrodesStacked capacitorsElectronic componentMaterials science

A ceramic electronic component includes a first internal electrode that includes a first opposed section and a first extraction section. The first opposed section is opposed to a second internal electrode with a ceramic layer interposed therebetween. The first extraction section is located closer to a first end surface than the first opposed section. The first extraction section includes a first thick section. The first thick section is thicker than a first central section of the first opposed section. The first opposed section includes a first base end section opposed to a second tip section of the second internal electrode closer to the first end surface, with the ceramic layer interposed therebetween, and the first base end section includes a first thin section. The first thin section is thinner than the first central section.

Owner:MURATA MFG CO LTD

A kind of aluminum silicon carbide ceramic substrate for LED

Owner:江苏卓远半导体有限公司

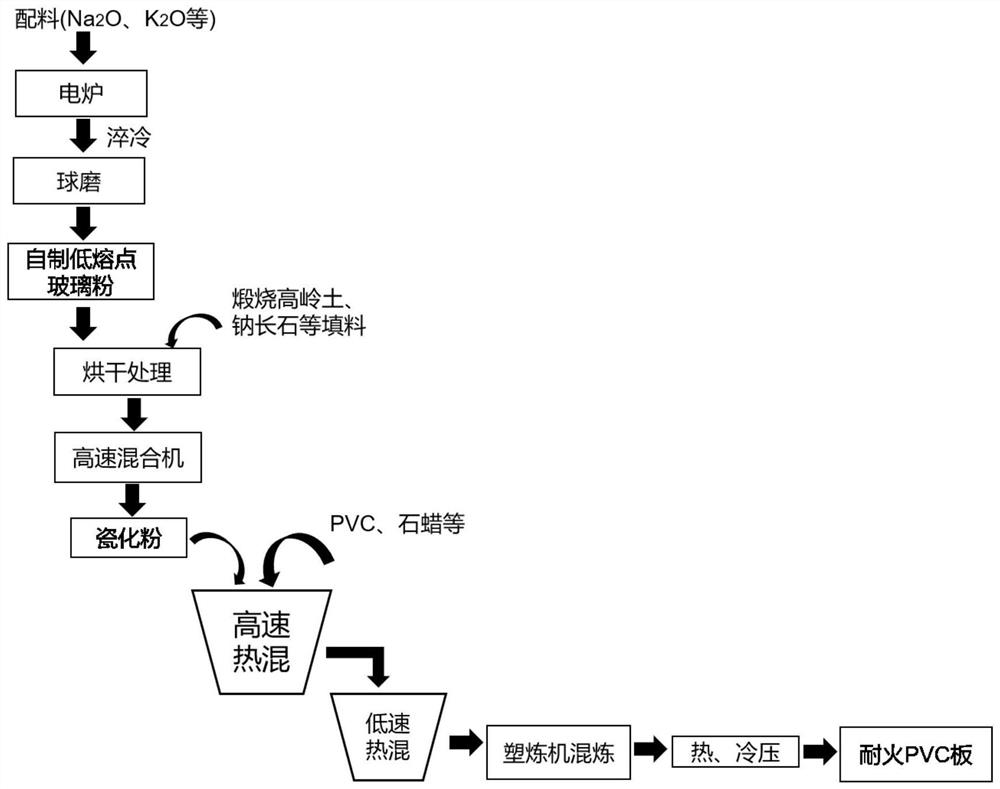

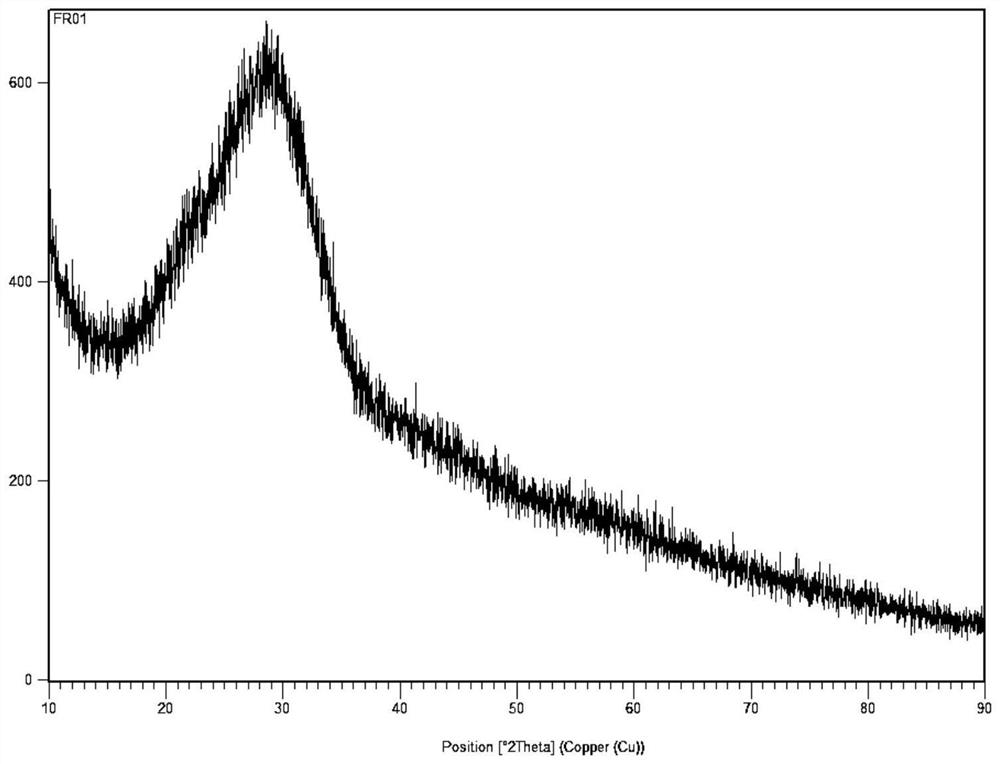

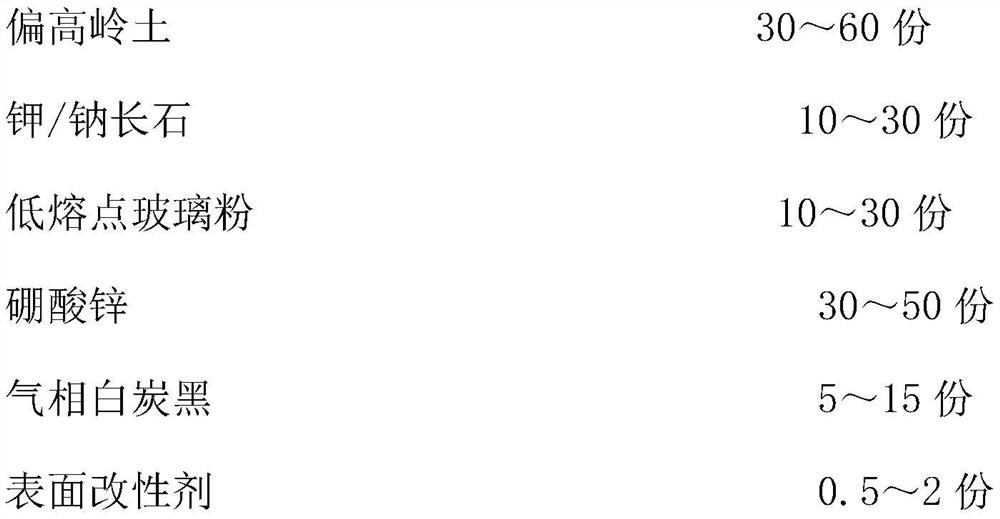

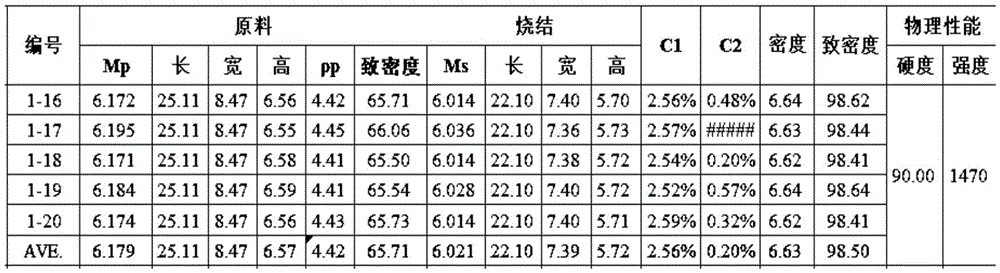

Ceramic powder and application thereof

The invention provides ceramic powder comprises the following components in parts by mass: 30-60 parts of metakaolin, 10-30 parts of potassium / albite, 10-30 parts of low-melting-point glass powder, 30-50 parts of zinc borate, 5-15 parts of fumed silica and 0.5-2 parts of a surface modifier. According to the particle size effect of ceramic sintering, the particle size of a filler is refined, and meanwhile, the particle size among the components is also homogenized, so that the effect of sintering into ceramic is obviously improved. In addition, by adding self-made low-melting-point glass powder, the ceramic forming performance of the ceramic polyolefin at medium temperature and high temperature is improved, the strength of the ceramic powder and a PVC board after ceramic forming is higher,and a ceramic body formed by sintering has fewer cracks and is small in deformation.

Owner:嘉兴市吉奥新材料科技有限公司

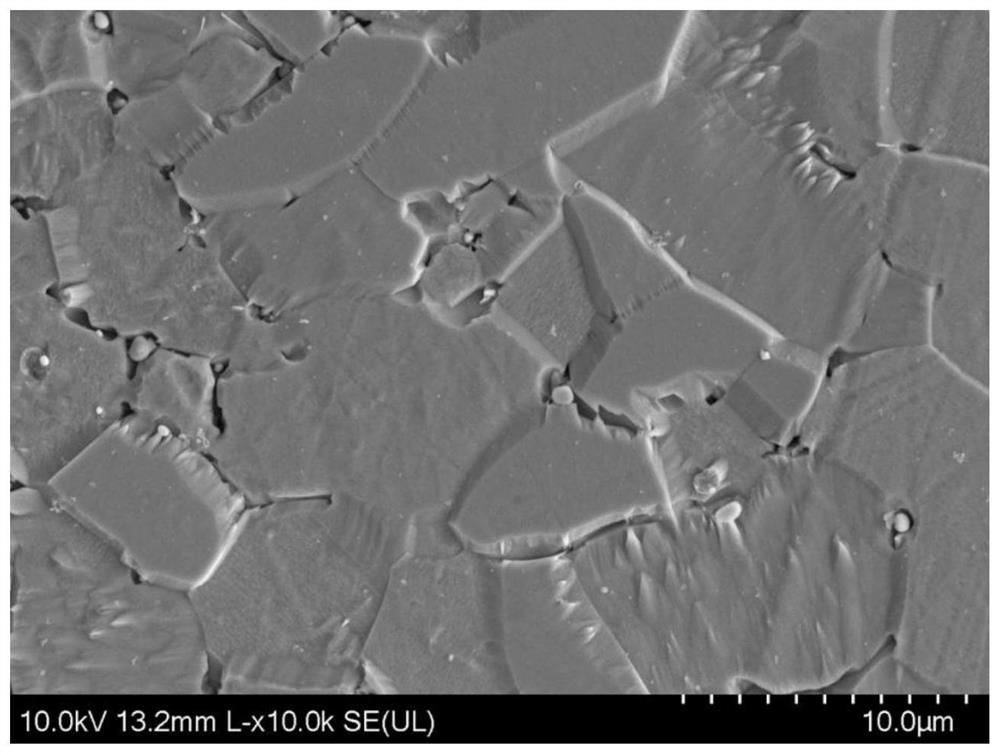

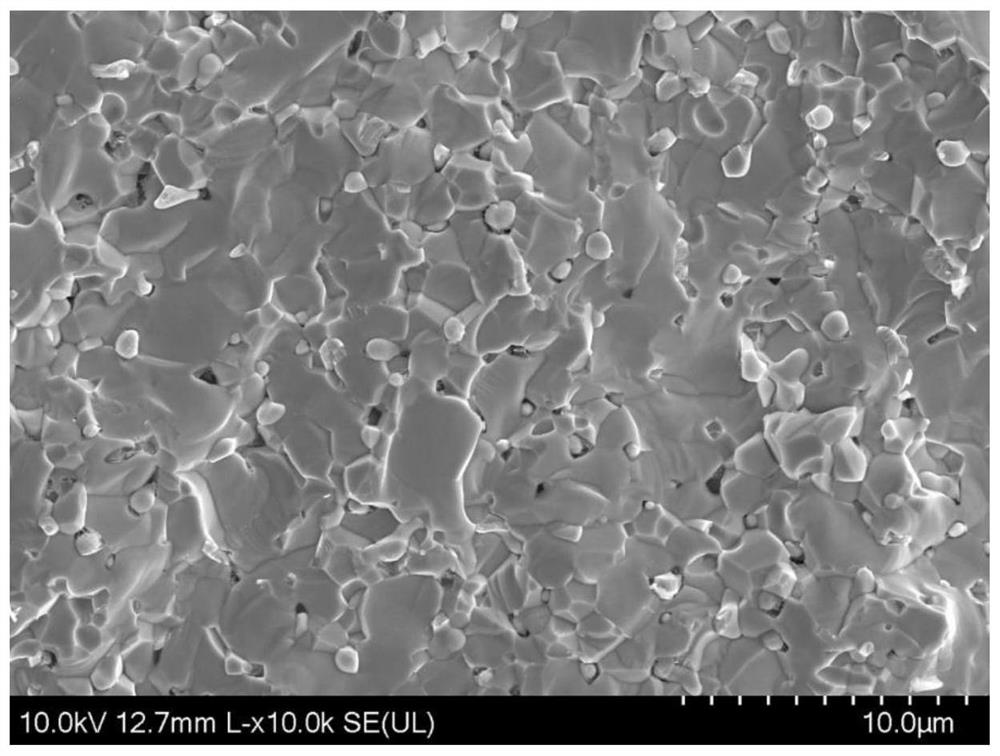

Ti(C, N) based metal ceramic

The invention discloses a Ti(C, N) based metal ceramic, which comprises: C black, WC, Ni, Ti, Mo, Cr3C2, N, and Cr. The Ti(C, N) based metal ceramic provided by the invention improves the performance of metal ceramic, makes the metal ceramic have stronger market competitiveness, and broadens the application field of metal ceramic hard alloy.

Owner:河源富马硬质合金股份有限公司

A ceramic substrate for LED

The invention discloses a ceramic substrate for LED, which optimizes various raw materials in the LTCC preparation process, using aluminum nitride, boron nitride, aluminum oxide and beryllium oxide as the main raw materials. At the same time, glass sintering aids, copper and aluminum are added. Additives such as alloy nanoparticles, rare earth oxides, solvents, plasticizers, dispersants and binders further optimize the physical and chemical properties of the ceramic substrate. The thermal conductivity of the ceramic substrate in this application is greater than 400W / (m·k), and the bending resistance is The strength is greater than 300Mpa, and the dielectric constant is less than 2. At the same time, through conventional LTCC preparation methods, the main raw materials and additives can be prepared into ceramic substrates with high conductivity. The preparation process is simple and is conducive to industrialization.

Owner:GANSU RONGBAO IND GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com