Ceramic firing kiln with controllable firing atmosphere

A kind of atmosphere and kiln technology, which is applied in the direction of furnace, charge, muffle furnace, etc., can solve problems not related to the control of the atmosphere in the kiln, improve flexibility and convenience of operation, and reduce carbon dioxide and other harmful gas emissions , The effect of improving the performance of ceramics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

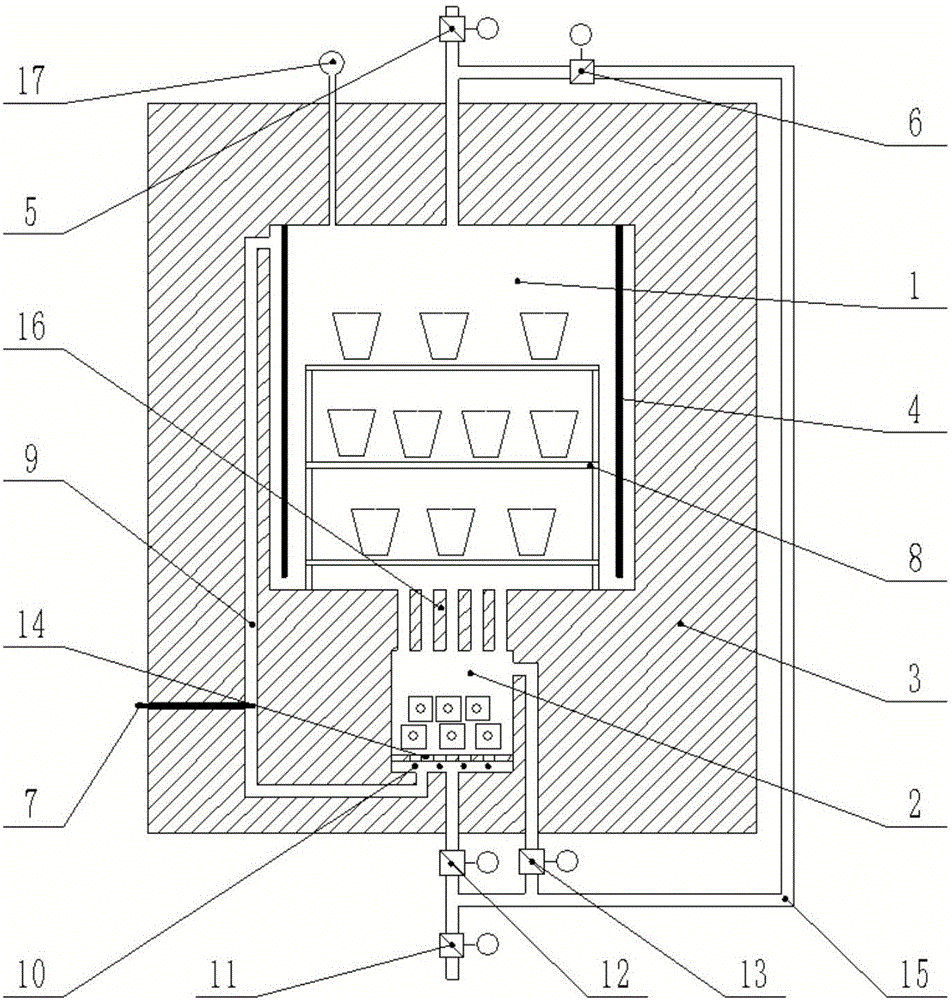

[0013] The ceramic firing kiln with controllable firing atmosphere proposed by the present invention has a structure such as figure 1 As shown, it includes the thermal insulation outer wall 3, the firing zone 1 and the atmosphere generation zone 2, the firing zone 1 and the atmosphere generation zone 2 are located in the inner cavity of the thermal insulation outer wall 3, the gas in the firing zone 1 and the gas in the atmosphere generation zone 2 The gas is connected through the porous partition 16, and the gas internal circulation passage 9 and the gas external circulation passage 15 are respectively provided between the firing zone 1 and the atmosphere generation zone 2, and the internal circulation gate 7 is provided on the gas internal circulation passage 9. The upper heater 4 is arranged along the four walls in the firing area 1, and the support shed plate 8 is arranged in the firing area. 17 and the recycle gas outlet, the recycle gas outlet is provided with an exhaust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com