High-strength flame-retardant cable special material and preparation method thereof

A technology for flame-retardant cables and special materials, which is applied in the field of special materials for cables, and can solve problems such as flammability restrictions and wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

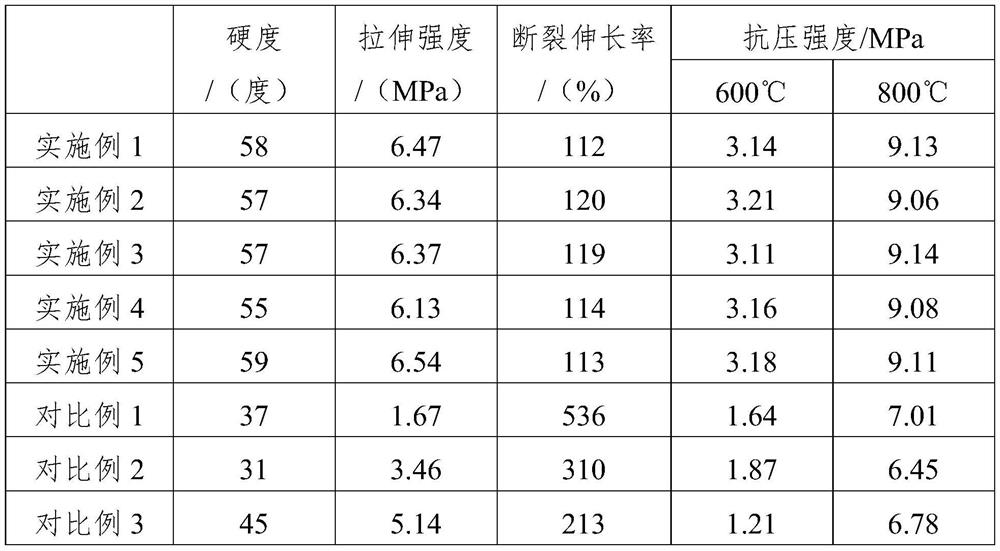

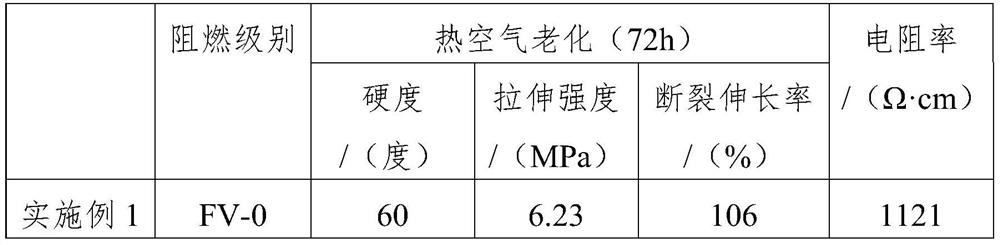

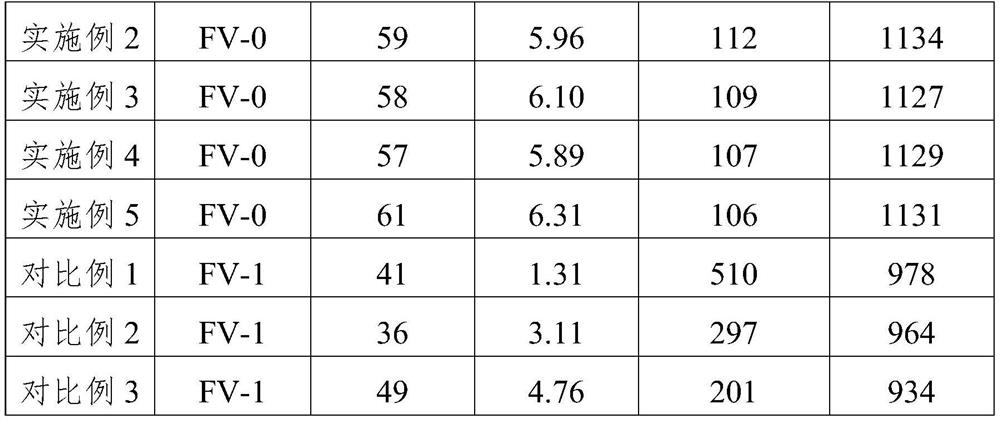

Examples

Embodiment 1

[0039]A high-strength flame-retardant cable special material, the cable special material includes the following raw materials in parts by weight: 100 parts of methyl vinyl silicone rubber, 5 parts of boron oxide, 15 parts of reinforcing filler, 30 parts of low melting point glass powder, magnesium hydroxide 15 parts, 10 parts of aluminum hydroxide, 1 part of modified flame retardant, 8 parts of structure control agent, 3 parts of 2,4-dichlorobenzoyl, 20 parts of decabromodiphenyl.

[0040] The structure control agent is prepared by mixing magnesia, wollastonite and zirconia in a molar ratio of 6:5:1.

[0041] The preparation method of modified flame retardant comprises the steps:

[0042] (1) Weigh an appropriate amount of hexachlorocyclotriphosphazene, 4,4-dihydroxydiphenyl sulfone, and acetonitrile into reaction kettle A, and mix them uniformly by ultrasonic mixing for 15 minutes;

[0043] (2) Add an appropriate amount of triethylamine to the reactor A, and the molar ratio ...

Embodiment 2

[0057] A special material for high-strength flame-retardant cables. The special material for cables includes the following raw materials in parts by weight: 120 parts of methyl vinyl silicone rubber, 1 part of boron oxide, 20 parts of reinforcing filler, 20 parts of low melting point glass powder, magnesium hydroxide 20 parts, 5 parts of aluminum hydroxide, 5 parts of modified flame retardant, 5 parts of structure control agent, 5 parts of 2,4-dichlorobenzoyl, 15 parts of decabromodiphenyl ether.

[0058] The structure control agent is prepared by mixing magnesia, wollastonite and zirconia in a molar ratio of 6:5:1.

[0059] The preparation method of modified flame retardant comprises the steps:

[0060] (1) Weigh an appropriate amount of hexachlorocyclotriphosphazene, 4,4-dihydroxydiphenyl sulfone, and acetonitrile into reaction kettle A, and mix them uniformly by ultrasonic mixing for 20 minutes;

[0061] (2) Add an appropriate amount of triethylamine to the reactor A, and ...

Embodiment 3

[0069] A high-strength flame-retardant cable special material, the cable special material includes the following raw materials in parts by weight: 100 parts of methyl vinyl silicone rubber, 5 parts of boron oxide, 15 parts of reinforcing filler, 30 parts of low melting point glass powder, magnesium hydroxide 15 parts, 10 parts of aluminum hydroxide, 1 part of modified flame retardant, 8 parts of structure control agent, 3 parts of 2,4-dichlorobenzoyl, 20 parts of decabromodiphenyl ether.

[0070] The structure control agent is prepared by mixing magnesia, wollastonite and zirconia in a molar ratio of 6:5:1.

[0071] The preparation method of modified flame retardant comprises the steps:

[0072] (1) Weigh an appropriate amount of hexachlorocyclotriphosphazene, 4,4-dihydroxydiphenyl sulfone, and acetonitrile into reaction kettle A, and mix them uniformly by ultrasonic mixing for 20 minutes;

[0073] (2) Add an appropriate amount of triethylamine to the reactor A, and the molar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com