Ti(C, N) based metal ceramic

A base metal and ceramic technology, applied in the field of Ti-based cermets, can solve the problems of various cermet formulations, unstable performance, uneven performance of cermets, etc., to improve the performance of cermets, strengthen market competitiveness, and broaden applications. field effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

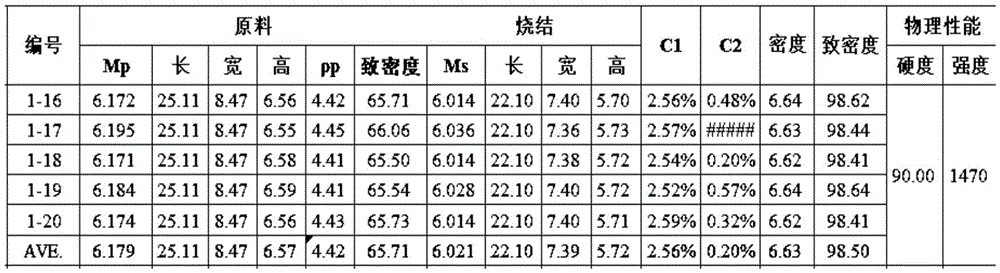

[0016] As shown in Table 1, the formula and the weight percentage of each component are as follows:

[0017] Table 1

[0018] Element Optimum content range (wt%) C / N 6 / 4 C black 1.5 WC 15 Ni 40 Ti / Mo ≥5 / 3 Cr3C2 ≤1 N ≤2.7 Ni / (Ni+Cr) 0.98

Embodiment 2

[0020] As shown in table 2, formula and each composition weight percentage are as follows:

[0021] Table 2

[0022] Element Optimum content range (wt%) C / N 7 / 3 C black 1 WC 6.5 Ni 25 Ti / Mo ≥5 / 3 Cr3C2 ≤1 N ≤2.7 Ni / (Ni+Cr) 0.6

[0023] In the above-mentioned embodiment scheme, the proportioning principle of each element of the formula is as follows:

[0024] 1) The Ti content is related to the Mo content and the total C black content. If the Ti content is too high, Ni will be produced. 3 The intermetallic hard phase of Ti is very brittle. Ni 3 The Ti interstitial phase is generated when the solid solution is cooled. Generally, Ti / Mo=5 / 3 is controlled, and the content of C by weight is 1-1.5%.

[0025] 2)TiC 0.7 N 0.3 Relationship with Ni content: When the Ni content is 20-25Vol% (volume percentage), the strength is the highest, and the hardness decreases linearly with the increase of Ni content. Ti(C x N y ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com