Kieselguhr-nickel slag composite adsorption material capable of recovering heavy metal ions and preparation of composite adsorption material

A technology of composite adsorption materials and heavy metal ions, which is applied in the fields of adsorbing water/sewage treatment, other chemical processes, chemical instruments and methods, etc., can solve the problems of environmental pollution, low utilization rate of limestone, etc. The effect of social benefit and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

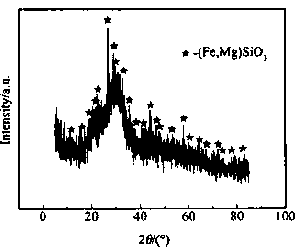

Image

Examples

Embodiment 1

[0023] The weight ratio of the raw material formula in this example: nickel slag is 50wt%, diatomaceous earth is 40wt%, and limestone is 10wt%. Weigh the two raw materials according to the formula, place them in a ball mill and grind them for 12 hours. The ground slurry is filtered and dehydrated, dried and crushed at 100°C to obtain a total material of less than 30 meshes; add the binder polyvinyl alcohol (PVA), and the dosage is 18wt% of the total material; mix evenly in the mixer, trap the material for 12 hours, and press the mixture into shape; the formed sample is dried at 100 ° C for 12 hours; the sample is placed in a muffle furnace for reaction sintering, and the reaction sintering temperature is 800°C, the holding time is 3 hours, and the furnace is cooled to room temperature to obtain the prepared composite material.

[0024] The prepared composite material was subjected to the adsorption experiment of heavy metal ions in wastewater. The ratio of adsorbent sample / was...

Embodiment 2

[0026] The weight ratio of the raw material formula in this example: nickel slag is 40wt%, diatomaceous earth is 40wt%, and limestone is 20wt%. Weigh the two raw materials according to the formula, place them in a ball mill and grind for 13 hours, filter and dehydrate the ground slurry, dry and crush at 110°C, and obtain a total material of less than 30 meshes; add binder PVA, the amount is 15wt% of the total material ; Mix evenly in the mixer, trap the material for 10 hours, and press the mixed material to form; the formed sample is dried at 110°C for 12 hours; the sample is placed in a muffle furnace for reaction sintering, the reaction sintering temperature is 850°C, and the holding time for 3 hours, and cooled to room temperature with the furnace to obtain the prepared composite material.

[0027] The prepared composite material was subjected to the adsorption experiment of heavy metal ions in wastewater. The ratio of adsorbent sample / wastewater dosage was 1g / 25mL. The ads...

Embodiment 3

[0029] The weight ratio of the raw material formula in this example: nickel slag is 50wt%, diatomaceous earth is 30wt%, and limestone is 20wt%. Weigh the two raw materials according to the formula, place them in a ball mill and grind for 15 hours, filter and dehydrate the ground slurry, dry and crush at 90°C, and obtain a total material of less than 30 meshes; add the binder PVA, and the dosage is 12wt% of the total material ; Mix evenly in the mixer, trap the material for 14 hours, and press the mixture into shape; dry the formed sample at 90°C for 12 hours; place the sample in a muffle furnace for reaction sintering, the reaction sintering temperature is 900°C, and keep warm The time is 5 hours, and the furnace is cooled to room temperature to obtain the prepared composite material.

[0030]The prepared composite material was subjected to the adsorption experiment of heavy metal ions in wastewater. The ratio of adsorbent sample / wastewater dosage was 1g / 25mL. The adsorption e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com