High-activity submicron boron carbide ceramic powder and low-temperature in-situ preparation method thereof

A boron carbide ceramic, sub-micron technology, applied in the chemical industry, climate sustainability, greenhouse gas reduction, etc., can solve the problems of long and complex process, waste of water resources, complicated operation, etc., to achieve simple process, reduce The effect of low sintering temperature and reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

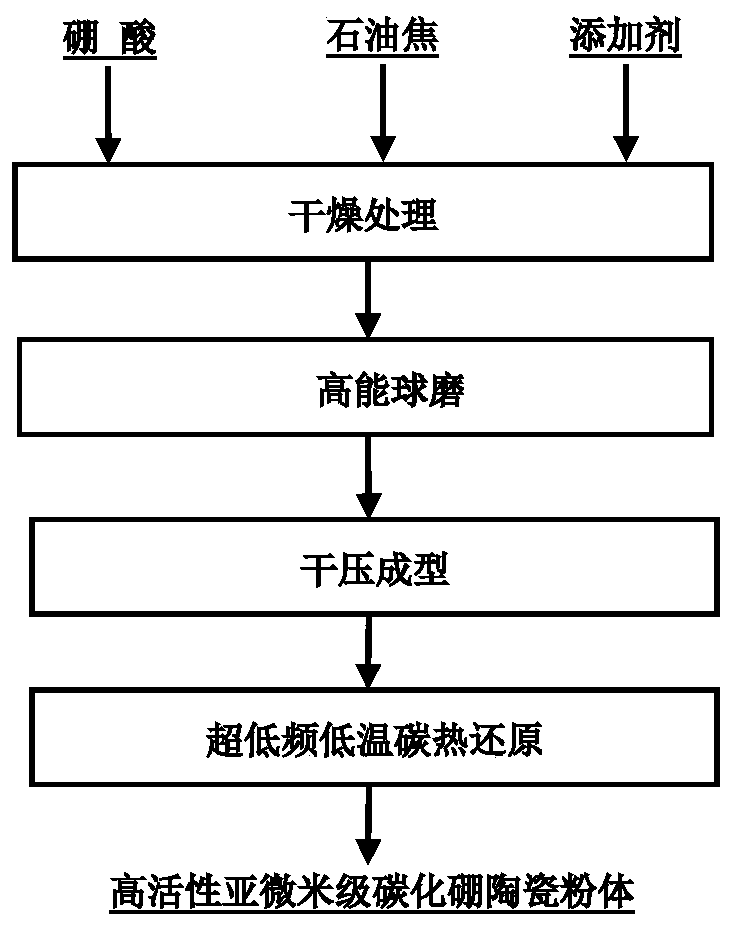

[0034] The low-temperature in-situ preparation method of the high-activity submicron boron carbide ceramic powder of the present invention, such as figure 1 shown, including the following steps:

[0035] (1) Boric acid, petroleum coke, and rare earth oxide additives are compounded according to the weight ratio of 68-75wt.% of boric acid, 24-30wt.% of petroleum coke, and 0.2-8wt.% of rare earth oxide additives;

[0036] (2) Put the mixed raw materials in a vacuum drying oven for drying treatment, the drying temperature is 80-400°C, the heating rate is 2-10°C / min, and the drying time is 0.2-2h;

[0037] (3) carrying out high-energy ball milling to the dried raw materials;

[0038] (4) Carry out dry pressing molding to block after the crushed powder;

[0039] (5) Place the bulk raw material in an ultra-low frequency heating furnace, and prepare high-activity submicron B in situ at 1200-1600 °C 4 C ceramic powder.

Embodiment 1

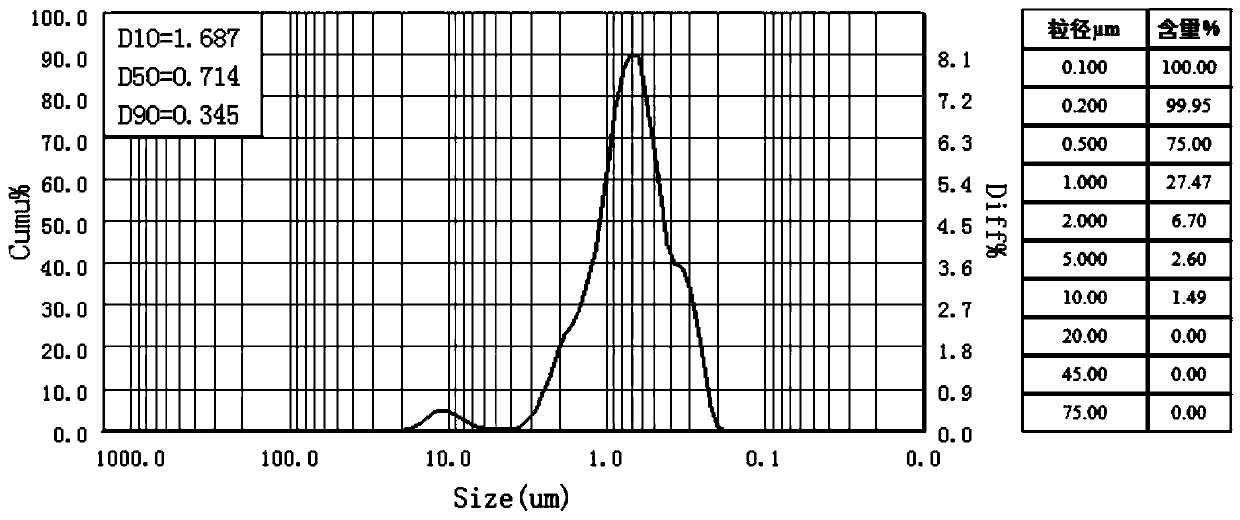

[0041] Take 72g of boric acid with a purity of 99.9% and a particle size range of 0 to 0.2mm, 27g of petroleum coke with a fixed carbon content of 88% and a particle size of 0 to 1mm, and 3g of Y 2 o 3 Carry out batching, put in the vacuum drying box that the heating rate is 5 ℃ / min and the temperature is 200 ℃ and dry for 1.5h, put the dried raw material in the high-energy ball mill ball mill of 300r / min for 40h, the ball material ratio is 8:1, put The crushed powder is formed into a block with a pressure of 120MPa for 6 minutes on a dry press molding machine, and the block is placed in an ultra-low frequency heating furnace at a temperature of 1500°C for 1.5 hours to obtain a mass fraction of C of 22.0%, Fe The mass fraction of <0.10%, the B / C molar ratio is 3.90, and the average particle size is 0.56μm, which is a highly active submicron boron carbide ceramic powder.

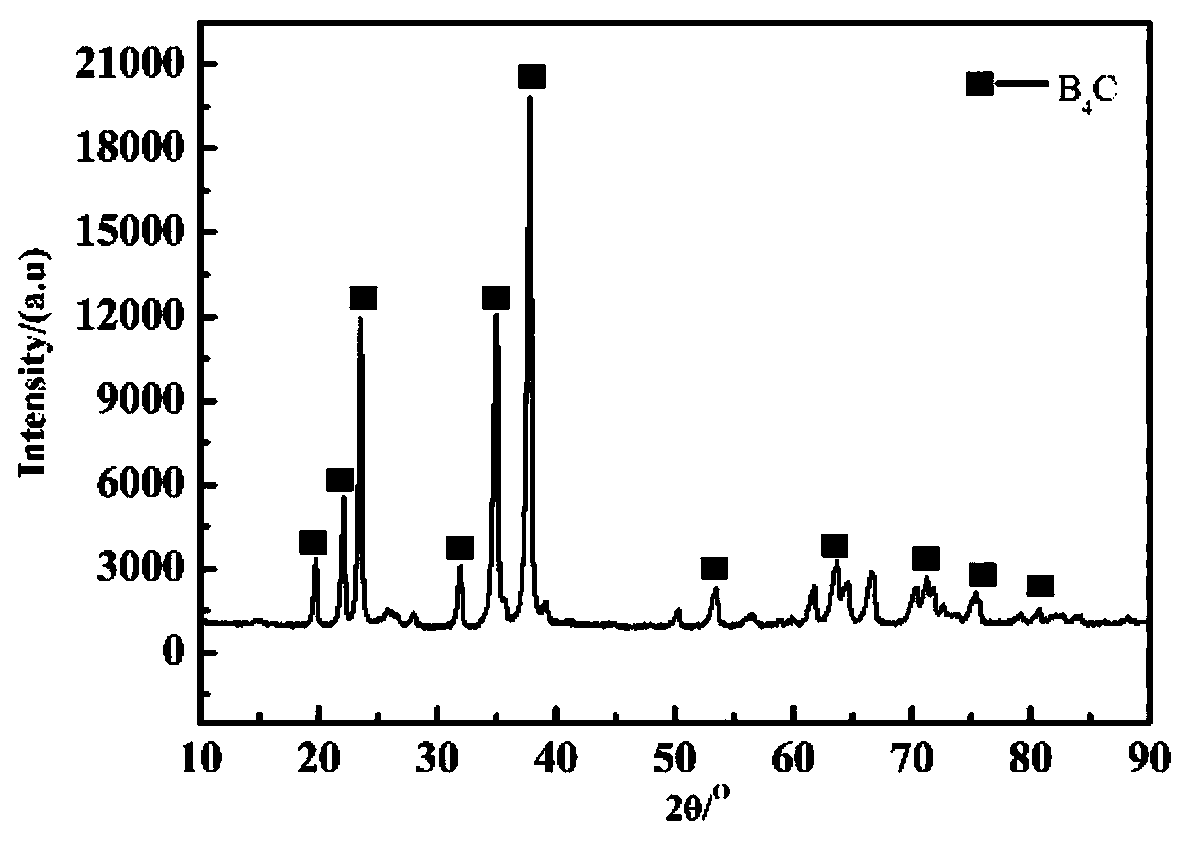

[0042] figure 2 For this embodiment, high activity submicron grade B 4 The XRD pattern of C ceramic po...

Embodiment 2

[0044] Get purity and be 99.6%, boric acid 69g that particle size range is 0.5~1mm, get fixed carbon content and be 86%, petroleum coke 30g that particle size range is 2.5~5mm, 1g La 2 o 3 Carry out batching, after being placed in the vacuum drying box that heating rate is 10 ℃ / min temperature is 350 ℃ and dried 0.5h, the raw material after the drying is placed in the high-energy ball mill ball mill of 500r / min 50h, and the ball-to-material ratio is 12:1, will The crushed powder is formed into a block at a pressure of 100 MPa for 8 minutes on a dry press molding machine, and the block is placed in an ultra-low frequency heating furnace at a temperature of 1600 ° C for 0.5 h to obtain a mass fraction of C of 22.6%, Fe The mass fraction of <0.10%, the B / C molar ratio is 3.64, and the average particle size is 0.84μm, which is a highly active submicron boron carbide ceramic powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com