Environment-friendly ablation-resistant ceramic silicone rubber composite material and preparation method thereof

A technology for ceramicizing silicone rubber and composite materials, which is applied in the field of silicone rubber composite materials, can solve the problems of high production cost of coating materials, poor resistance to ablation and ablation of insulating layers, etc., and achieves easy industrial production, good processing performance, good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

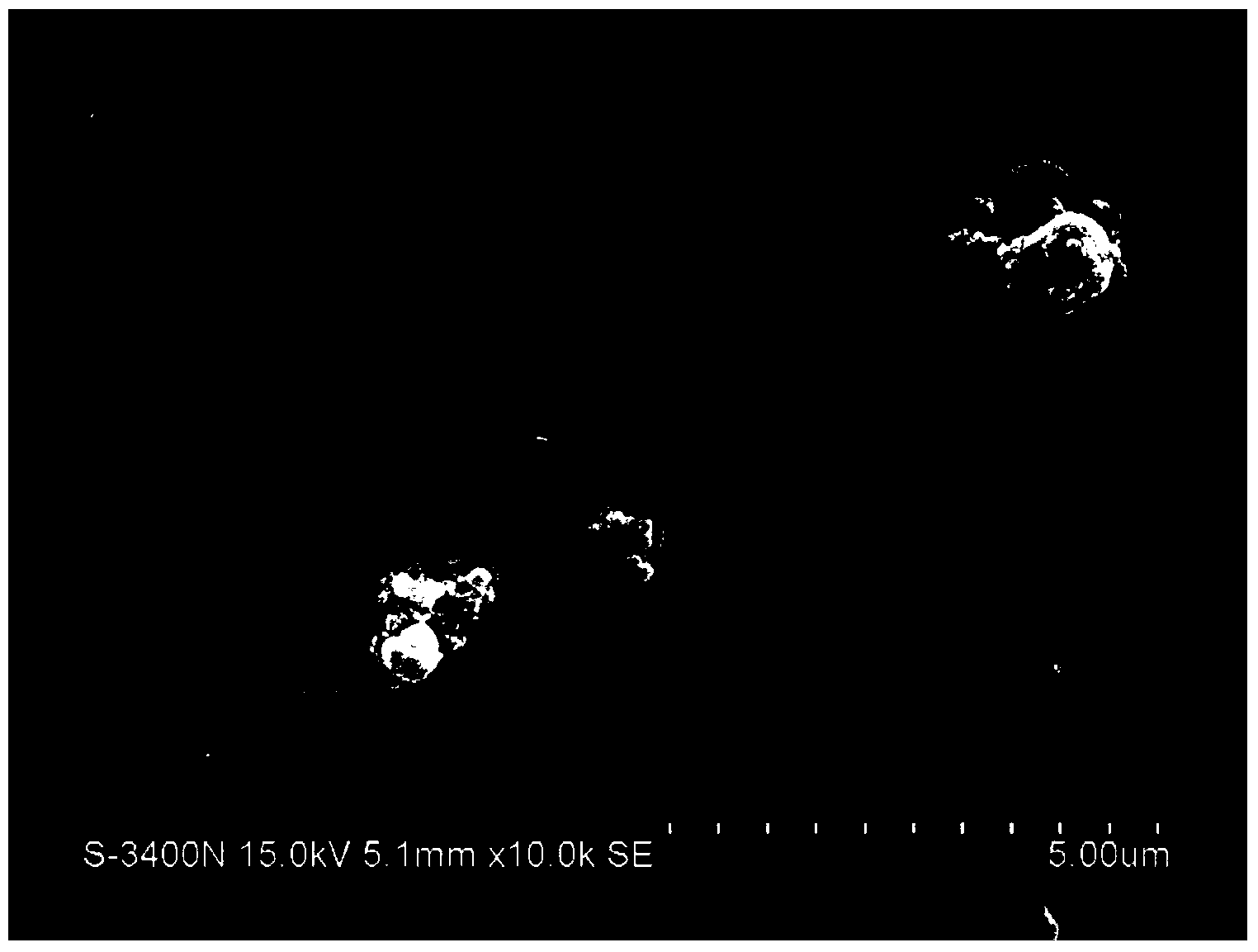

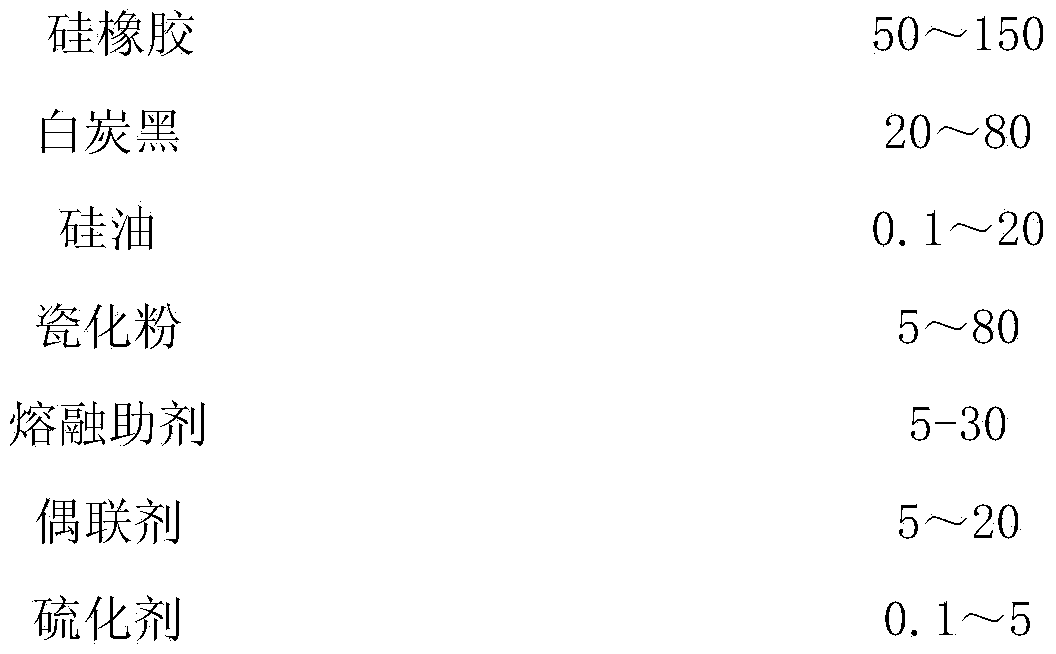

Embodiment 1

[0036]Mix 100g of silicone rubber methyl vinyl silicone rubber, 60g of fumed silica, and 11g of hexamethyldisilazane in an internal mixer at a temperature not higher than 80°C; then mix 10g of magnesium oxide, zirconia Add 10g, 1g of high vinyl silicone oil, 8g of hydroxy silicone oil, and 0.6g of hydrogen-containing silicone oil into the internal mixer, and knead the vitrified powder, silicone oil and the kneaded mixture evenly to form ceramic silicone rubber; Take out the good vitrified silicone rubber, and place it to cool down to 25°C-30°C; knead the ceramicized silicone rubber that has been placed and cooled to 25°C-30°C on an open mill, add 2 parts of vulcanizing agent, and the temperature is not higher than 50 ℃, so that the vulcanizing agent and the kneaded vitrified silicone rubber are evenly mixed into a sheet; after the sheet is released, it is formed by hot pressing at 165°C and 15MPa for 15 minutes with a 25-ton flat-panel vulcanizer; after molding, the material is...

Embodiment 2

[0038] Mix 100g of silicone rubber methyl vinyl silicone rubber, 60g of fumed silica, and 11g of hexamethyldisilazane in an internal mixer at a temperature not higher than 80°C; then mix 10g of magnesium oxide, aluminum oxide 10g, 10g of borax, 2g of high vinyl silicone oil, 8g of hydroxyl silicone oil, and 0.6g of hydrogen-containing silicone oil are added to the internal mixer, and the vitrified powder, silicone oil and the kneaded mixture are mixed evenly to form ceramic silicone rubber; Take out the kneaded vitrified silicone rubber, and place it to cool down to 25°C-30°C; knead the vitrified silicone rubber that has been placed and cooled to 25°C-30°C on an open mill, add 2 parts of vulcanizing agent, and keep the temperature constant. When the temperature is higher than 50°C, the vulcanizing agent and the kneaded vitrified silicone rubber are evenly mixed into a sheet; after the sheet is released, it is formed by hot pressing at 165°C and 15MPa for 15 minutes with a 25-to...

Embodiment 3

[0040] Mix 100g of silicone rubber methyl vinyl silicone rubber, 60g of fumed silica, and 11g of hexamethyldisilazane in an internal mixer at a temperature not higher than 80°C; then mix 10g of magnesium oxide, aluminum oxide Add 10g, lithium porcelain stone powder 5g, borax 10g, high vinyl silicone oil 2g, hydroxyl silicone oil 8g, and hydrogen-containing silicone oil 0.6g into the internal mixer, and make the porcelain powder, silicone oil and the mixed mixture evenly mixed to form Ceramic silicone rubber; take out the kneaded ceramic silicone rubber, and place it to cool down to 25°C-30°C; knead the ceramic silicone rubber cooled to 25°C-30°C on the open mill, add 2 parts Vulcanizing agent, the temperature is not higher than 50°C, so that the vulcanizing agent and the kneaded vitrified silicone rubber are evenly mixed into a sheet; after the sheet is released, use a 25-ton flat vulcanizer to press at 165°C and 15MPa for 15 minutes to form; forming Finally, the material is s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com