Epoxy anticorrosive coating

A technology of epoxy anti-corrosion coatings and pigments and fillers, which is applied in the direction of anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve the problems of high price and lack of anti-corrosion performance, improve mechanical properties, reduce curing shrinkage, reduce small reunion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

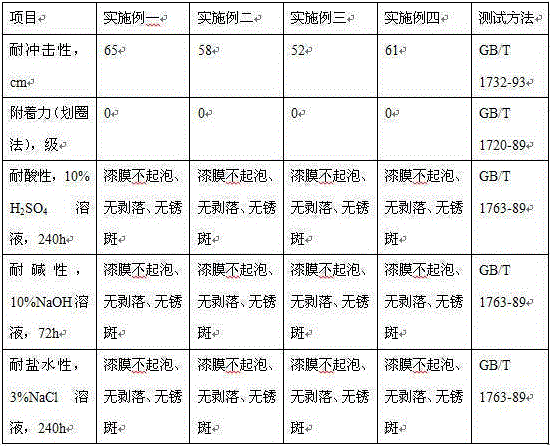

Embodiment 1

[0019] A kind of epoxy anticorrosion coating, described epoxy anticorrosion coating is made up of following components by mass percentage: resin is 60%, pigment and filler is 26%, and auxiliary agent is 14%; Described resin is by mass percentage by oil modified ring Oxygen resin 45%, oil-soluble phenolic resin 10% and hexamethoxymethylmelamine resin 5%; the pigments and fillers are composed of the following components by mass percentage: talcum powder 3%, mica powder 5.5%, bentonite 6.5%, nano Titanium dioxide-based composite particles 3.5%, silicon-aluminum-based hollow microspheres 7.5%. The auxiliary agent is composed of the following components by mass percentage: 1.5% dispersant, 0.5% defoamer, 1.5% coupling agent, 5.5% plasticizer, 3.5% curing agent, and 1.5% catalyst; the defoamer The agent is a polyether modified silicone defoamer, the coupling agent is a silane coupling agent, the plasticizer is an epoxy plasticizer, and the curing agent is modified dicyandiamide and ...

Embodiment 2

[0025] A kind of epoxy anticorrosion coating, described epoxy anticorrosion coating is made up of following components by mass percentage: resin is 60%, pigment and filler is 25%, and auxiliary agent is 15%; Described resin is by mass percentage by oil modified ring Oxygen resin 45%, oil-soluble phenolic resin 8% and hexamethoxymethyl melamine resin 7%; the pigments and fillers are composed of the following components by mass percentage: talcum powder 2.5%, mica powder 5.5%, bentonite 6.5%, nano Titanium dioxide-based composite particles 4%, silica-alumina-based hollow microspheres 8%. The auxiliary agent is composed of the following components by mass percentage: 1.5% dispersant, 0.6% defoamer, 1.9% coupling agent, 5.8% plasticizer, 3.7% curing agent, and 1.5% catalyst; the defoamer The agent is a polyether modified silicone defoamer, the coupling agent is a silane coupling agent, the plasticizer is an epoxy plasticizer, and the curing agent is modified dicyandiamide and seby...

Embodiment 3

[0031]A kind of epoxy anticorrosion coating, described epoxy anticorrosion coating is made up of following components by mass percentage: resin is 55%, pigment and filler is 28%, and auxiliary agent is 17%; Described resin is by mass percentage by oil modified ring Oxygen resin 40%, oil-soluble phenolic resin 5% and hexamethoxymethyl melamine resin 5%; the pigments and fillers are composed of the following components by mass percentage: talcum powder 3%, mica powder 6%, bentonite 7%, nano Titanium dioxide-based composite particles 4%, silica-alumina-based hollow microspheres 8%. The auxiliary agent is composed of the following components by mass percentage: 2% dispersant, 1.0% defoamer, 2% coupling agent, 6.0% plasticizer, 4% curing agent, and 2% catalyst; the defoamer The agent is a polyether modified silicone defoamer, the coupling agent is a silane coupling agent, the plasticizer is an epoxy plasticizer, and the curing agent is modified dicyandiamide and sebyl Acid dihydra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com