Measuring method of corrosion degree of desulfuration flue gas to chimney

A measurement method and chimney technology, applied in the direction of combustion method, waste gas exhaust device, combustion product treatment, etc., can solve the problems of damage to the anti-corrosion layer of the chimney lining, time-consuming, high risk, etc., to achieve easy analysis and processing, and convenient use , the result is intuitive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

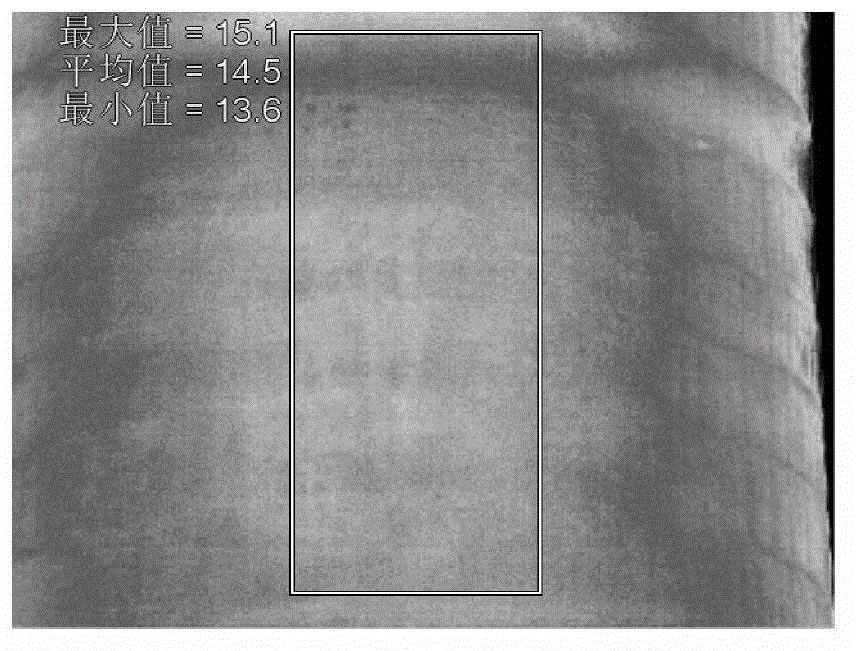

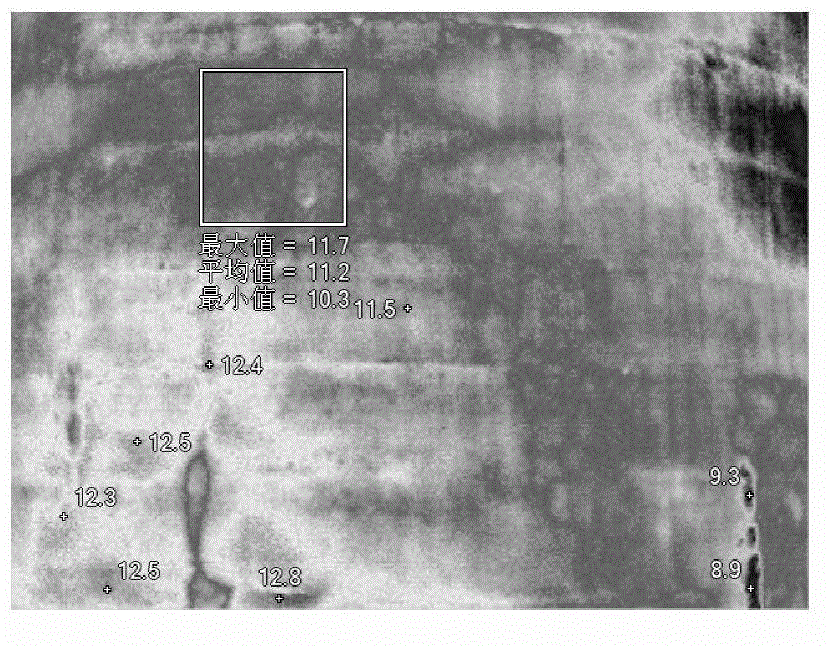

[0035] As shown in Figure 1-4, a method for measuring the degree of corrosion of the chimney by desulfurization flue gas is characterized in that the method uses an infrared thermal imager to detect the degree of corrosion of the chimney, and the method consists of the following steps:

[0036] (1) Determine the internal temperature t of the chimney according to the chimney temperature control device i ;

[0037] (2) Measure the outside air temperature t of the chimney with a thermometer 0 and the outer surface temperature t of the chimney measured by the infrared thermal imager wo ;

[0038] (3) Determine the total thermal resistance R of the chimney wall according to the material composition and thickness of the chimney 0 ;

[0039] (4) In the thermal image of a certain section of the chimney wall, find the part with uniform temperature as the reference area, and calculate the heat transfer resistance R of the outer surface of the chimney wall by formula ① w ;

[0040]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com