Process for preparing high-purity ethiprole through oxidation method

A technology of ethiprole and high purity, which is applied in the field of production and preparation of high-purity ethiprole, and can solve problems such as low yield, high cost, and complicated separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

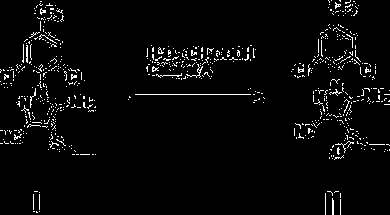

Image

Examples

Embodiment 1

[0040] Add 10.287kg (27mol) of ethiprole oxidation precursor, 107.26kg (1083mol) of dichloroethane into a 100L reactor, add 4.212kg (70.2mol) of acetic acid and 6.8175kg (70.2mol) of 35% hydrogen peroxide, and stir at 30°C About 10 hours. Sampling and follow-up, after the reaction was completed, 3.285 kg (31.6 mol) of sodium sulfite was slowly added, and the exotherm was obvious, which was controlled within 55 °C. Add sodium hydroxide solution to adjust the pH to 6-7, then heat up to reflux (about 80°C), then cool to below 10°C, crystallize, and filter with suction to obtain 10.50kg of crude solid, with a purity of 98.7%, and a crude yield of 96%, containing The peroxide impurity is 0.5%. After one recrystallization, the fine product with peroxidic impurity less than 0.3% is obtained, and the fine product yield is 93%.

[0041] The purity of the synthetic ethiprole: 99.4% (HPLC).

Embodiment 2

[0043] Add 10.287kg (27mol) of ethiprole oxidation precursor, 107.26kg (1083mol) dichloroethane layer into a 100L reactor, add 1.62kg (27mol) of acetic acid and 6.8175kg (70.2mol) of 35% hydrogen peroxide, and stir at 30°C About 20 hours. Sampling and follow-up, after the reaction was completed, 3.285 kg (31.6 mol) of sodium sulfite was slowly added, and the exotherm was obvious, which was controlled within 55 °C. Add sodium hydroxide solution to adjust the pH to 6-7, then heat up to reflux (about 80°C), then cool to below 10°C, crystallize, and filter with suction to obtain 10.41kg of crude solid, with a purity of 98.3%, and a crude yield of 95%, containing The peroxide impurity is 0.6%. After one recrystallization, the fine product with peroxidic impurity less than 0.3% is obtained, and the fine product yield is 92%.

[0044] The purity of the synthetic ethiprole: 99.3% (HPLC).

Embodiment 3

[0046] Add 10.287kg (27mol) of ethiprole oxidation precursor, 107.26kg (1083mol) of dichloroethane layer into a 100L reactor, add 4.212kg (70.2mol) of acetic acid and 6.8175kg (70.2mol) of 35% hydrogen peroxide, 30°C Stir for about 18 hours. Sampling and follow-up, after the reaction was completed, 3.285 kg (31.6 mol) of sodium sulfite was slowly added, and the exotherm was obvious, which was controlled within 55 °C. Add sodium hydroxide solution to adjust the pH to 6-7, then heat up to reflux (about 80°C), then cool to below 10°C, crystallize, and filter with suction to obtain 10.40kg of crude solid, with a purity of 97.8%, and a crude yield of 95%, containing The peroxide impurity is 0.8%. After recrystallization twice, a fine product with peroxidic impurity less than 0.3% is obtained, and the fine product yield is 91%.

[0047] The purity of the synthetic ethiprole: 99.1% (HPLC).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com