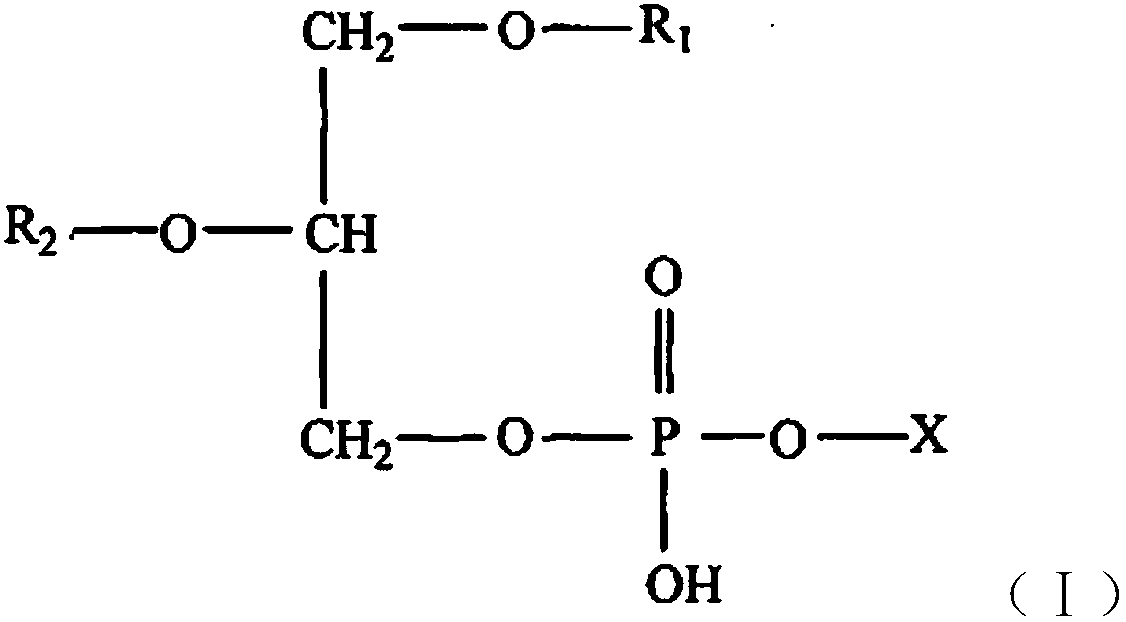

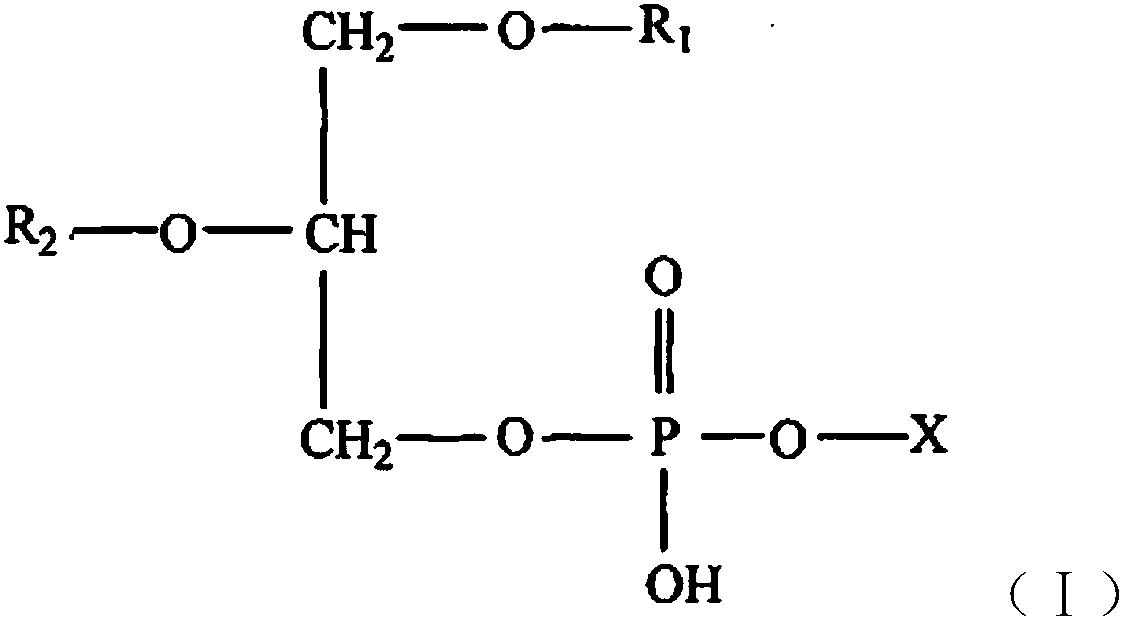

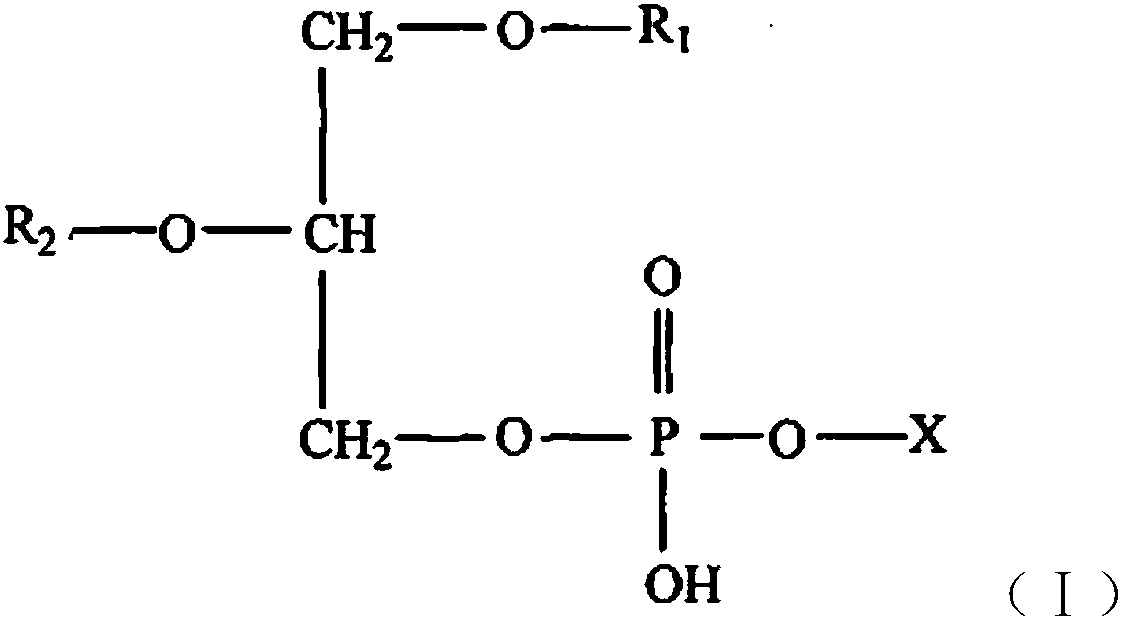

Phospholipid substance containing Omega-3 fatty acid and preparation method thereof

A technology of fatty acid and fatty acid acyl, applied in the field of biochemistry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Add 50g of soybean lecithin to 100g of refined fish oil ethyl ester (70% DHA content, 1.4% EPA content), stir and heat up to 100°C under vacuum conditions, maintain 10min with nitrogen to break the vacuum, add sodium ethoxide dropwise, and conduct a closed reaction under nitrogen conditions After 1 hr, the reaction was continued in vacuum for 3 hrs. After the reaction was completed, 200 mL of acetone was added, refrigerated and left to stand for crystallization overnight, vacuum filtered, and the filter cake was vacuum-dried to obtain 27.3 g of light yellow powder.

[0034] HPLC measures the content of phospholipids in the product, and the HPLC conditions are:

[0035] Chromatographic column: Si 60 chromatographic column, 5μ, 4.6×250mm;

[0036] Mobile phase: n-hexane / isopropanol / 1% acetic acid aqueous solution=8 / 8 / 1(V / V / V);

[0037] Flow rate: 1.0mL / min;

[0038] Column temperature: 30°C;

[0039] Detector: 210nm.

[0040] GC determination of the composition of fat...

Embodiment 2

[0043] Add 50g of soybean lecithin to 100g of refined fish oil ethyl ester (80% EPA content, 0.5% DHA content), stir and heat up to 130°C under vacuum conditions, maintain 10min with nitrogen gas to break the vacuum, add sodium ethoxide dropwise, and seal the reaction under nitrogen conditions After 0.5 hr, the reaction was continued in vacuum for 5 hr. After the reaction was completed, 200 mL of acetone was added, refrigerated and left to stand for crystallization overnight, vacuum filtered, and the filter cake was vacuum-dried to obtain 25.5 g of light yellow powder.

[0044] Utilize the method in " embodiment 1 " to measure phospholipid content and fatty acid composition in the product.

[0045] Measurement result shows: phospholipid content 88.2% in the obtained phospholipid thing, is made up of phosphatidic acid, phosphatidylethanolamine, phosphatidylcholine and phosphatidylinositol; %.

Embodiment 3

[0047] Add 50g of soybean lecithin to 150g of refined fish oil methyl ester (95% DHA content, 0.7% EPA content), stir and heat up to 130°C under vacuum conditions, maintain 10min with nitrogen gas to break the vacuum, add sodium methoxide dropwise, and conduct a closed reaction under nitrogen conditions After 1 hr, the reaction was continued in vacuum for 4.5 hrs. After the reaction was completed, 250 mL of acetone was added, refrigerated and left to stand for crystallization overnight, vacuum filtered, and the filter cake was vacuum-dried to obtain 28.3 g of light yellow powder.

[0048] Utilize the method in " embodiment 1 " to measure phospholipid content and fatty acid composition in the product.

[0049] The measurement result shows: phospholipid content 81.6% in the obtained phospholipid thing, is made up of phosphatidic acid, phosphatidylethanolamine, phosphatidylcholine and phosphatidylinositol; DHA accounts for 89.6% of total fatty acid content, and EPA accounts for 0....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com