Methane reforming transformation separator based on ion membrane reactor

A separation device and ion membrane technology, applied in the direction of inorganic chemistry, chemical instruments and methods, non-metallic elements, etc., can solve the problems of industrial application limitations, low product separation efficiency, incomplete product research, etc., to achieve simple operation, separation High efficiency and efficient separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

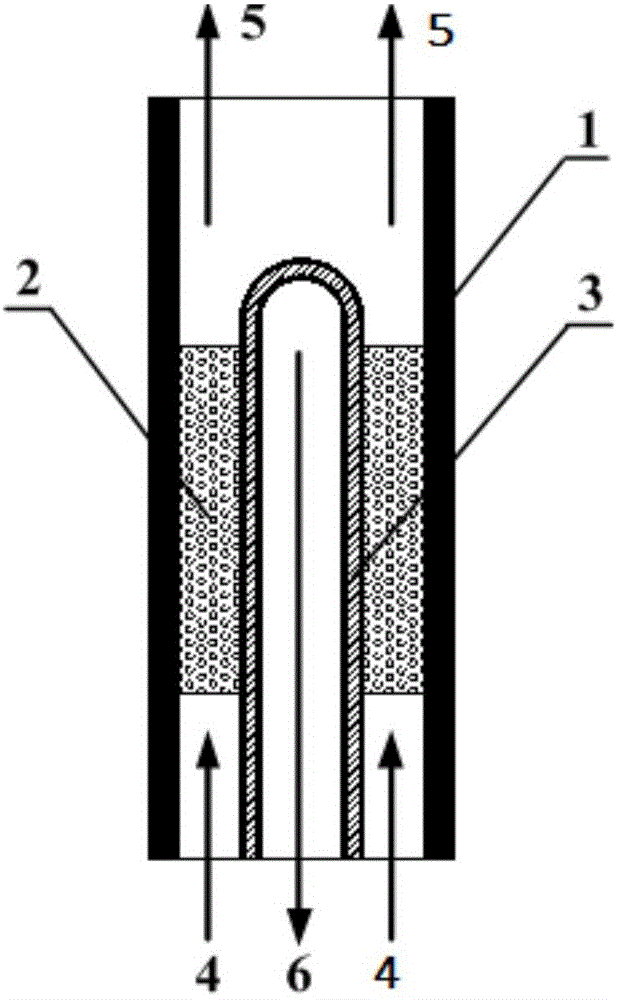

[0015] Embodiment 1: see figure 1 , a methane reforming conversion separation device based on an ionic membrane reactor, comprising: a quartz tube reactor 1, a catalyst bed 2, an ionic membrane 3, a reaction gas inlet 4, a gas product outlet 5, and a gas separation product outlet 6;

[0016] The quartz tube reactor 1 is used to support the catalyst bed 2 and the ion membrane 3;

[0017] The catalyst bed 2 is used to place the catalyst, and the reaction gases are CH4 and CO2;

[0018] The ionic membrane 3 is in an inverted U shape, and is arranged in the middle and lower part of the inner side of the quartz tube reactor 1; the ionic membrane 3 is composed of an anode, a cathode and an electrolyte, wherein the outermost layer is an anode, the middle is an electrolyte, and the innermost layer is an anode. The layer is the cathode; when an appropriate voltage is given on both sides of the ion membrane 3, the protons and cations of hydrogen are directionally migrated to both sides...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com