Method for calculating output air flow of air compressor of hydrogen fuel cell automobile

An air compressor and air flow technology, applied in fuel cells, electrical components, circuits, etc., can solve problems such as increased hydrogen consumption, decreased output power of stacks, errors, etc. Effect of reaction rate and output power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to make the purpose, technical solutions and beneficial effects of the present invention clearer, the preferred embodiments of the present invention will be described in detail below, so as to facilitate the understanding of the skilled person.

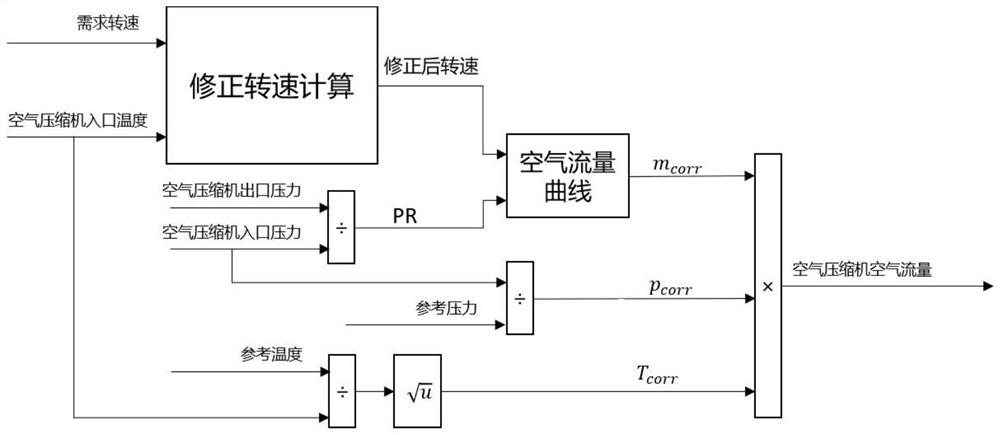

[0043] The method for calculating the output air flow rate of the hydrogen fuel cell vehicle air compressor comprises the following steps:

[0044] S1, collect air compressor operation data, including demand speed, inlet temperature, reference temperature, inlet pressure, outlet pressure, dynamic response time of air compressor;

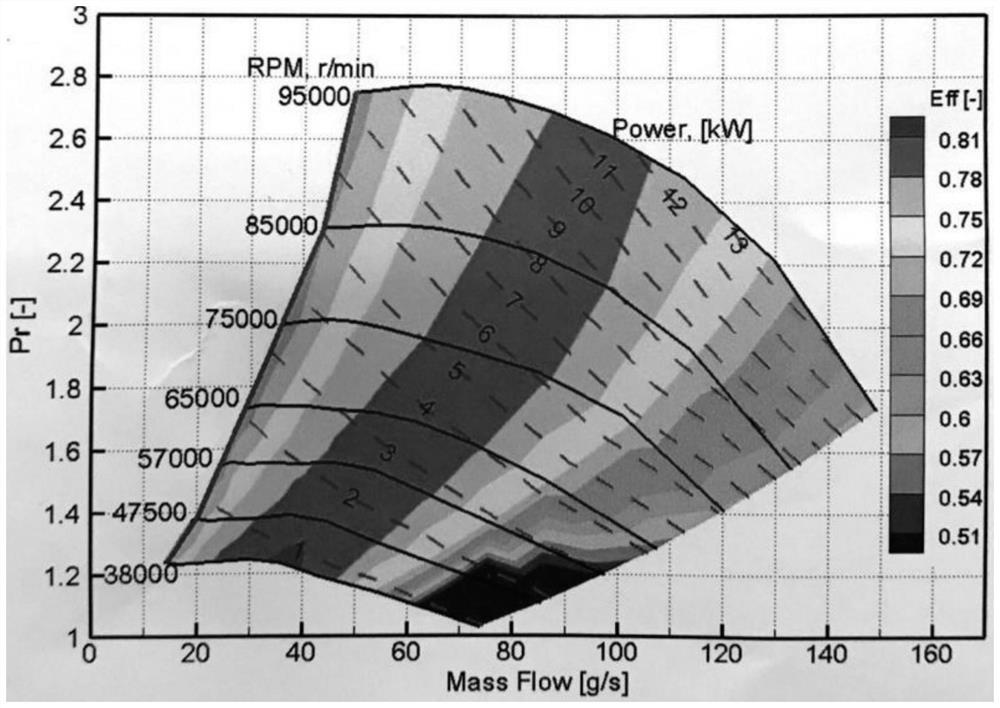

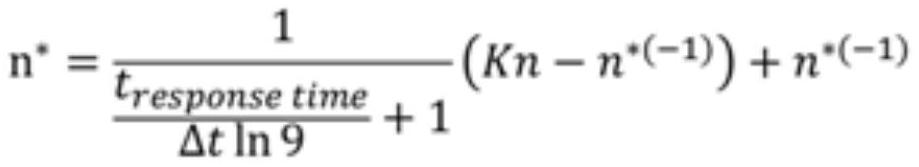

[0045] Among them, the required speed is obtained from the "Product Performance Curve" provided by the air compressor manufacturer according to the difference in the required intake air volume of the FCU under different working conditions. The reference temperature refers to the corresponding fluid temperature under standard working conditions; the dynamic response time of the air compressor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com