Lossless magnesium and magnesium alloy secondary formation method

A secondary chemical formation and magnesium alloy technology, which is applied in the coating process of metal materials, can solve the problems of high production cost of defective products, and achieve the effects of slow reaction rate, reduced production cost and stable rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

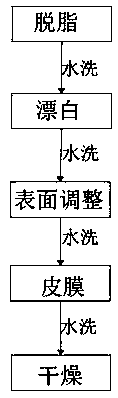

Image

Examples

Embodiment 1

[0031] The invention discloses a secondary chemical formation method of non-destructive magnesium and magnesium alloys, which comprises the following steps:

[0032] Degreasing: Prepare a degreasing solution consisting of 1% sodium hydroxide, 1% sodium carbonate and 0.5% anionic surfactant, and soak the magnesium or magnesium alloy workpiece in the degreasing solution at 80 degrees Celsius for 10 minutes.

[0033] Since the workpiece undergoing secondary chemical formation has been processed once, the surface of the workpiece will inevitably be stained with grease or mineral oil when it contacts the tool and machine tool during the processing process. The grease or mineral oil covering the surface of the workpiece will block the workpiece The contact between the matrix and the medicament makes it difficult to carry out subsequent reactions. Therefore, before the surface treatment of the workpiece, it is necessary to pretreat the workpiece with a degreasing solution to remove t...

Embodiment 2

[0055] The difference between this embodiment and embodiment 1 is:

[0056] In this embodiment, the degreasing solution is composed of 5% sodium hydroxide, 5% sodium carbonate and 2.5% anionic surfactant. Since the content of each component in this embodiment has increased relative to Example 1, the concentration of sodium hydroxide and anionic surfactant in the degreasing solution is higher, so the degreasing temperature is set to 50 degrees Celsius in this embodiment, and the degreasing operation continues The degreasing operation can be completed in 7 minutes.

[0057] In this embodiment, the bleach solution is composed of 20% hydrogen peroxide, 30% ammonium bifluoride, 3% citric acid, 3% tannic acid and water. The content of each component in the bleaching solution is greatly improved compared to Example 1, so the concentration of substances such as hydrogen peroxide, ammonium bifluoride, citric acid and tannic acid that are dissociated and available for dissociation in t...

Embodiment 3

[0061] The difference between this embodiment and embodiment 1 is:

[0062] In this embodiment, the degreasing solution is composed of 10% sodium hydroxide, 10% sodium carbonate and 5% anionic surfactant. As the concentration of each component in the degreasing liquid increases, the concentration of sodium hydroxide and anionic surfactant in the degreasing liquid is higher, and the degreasing reaction proceeds faster. In this embodiment, the degreasing temperature is set to 50 degrees Celsius. Since the concentration of sodium hydroxide and anionic surfactant in the degreasing liquid is large, the degreasing operation can be completed in 5 minutes.

[0063] In this embodiment, the bleach solution is composed of 30% hydrogen peroxide, 50% ammonium bifluoride, 5% citric acid, 5% tannic acid and water. Due to the relatively high components in the bleaching solution, the dissociated and dissociated hydrogen peroxide, ammonium bifluoride, citric acid, and tannic acid in the bleach...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com