High-adhesive-force emulsion for cigarette packet film and preparation method of high-adhesive-force emulsion

A high-adhesion and thin-film technology, applied in the field of emulsion, can solve the problems of poor alcohol resistance to scrubbing and poor adhesion, and achieve excellent adhesion, good adhesion, and improved conversion rate and stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

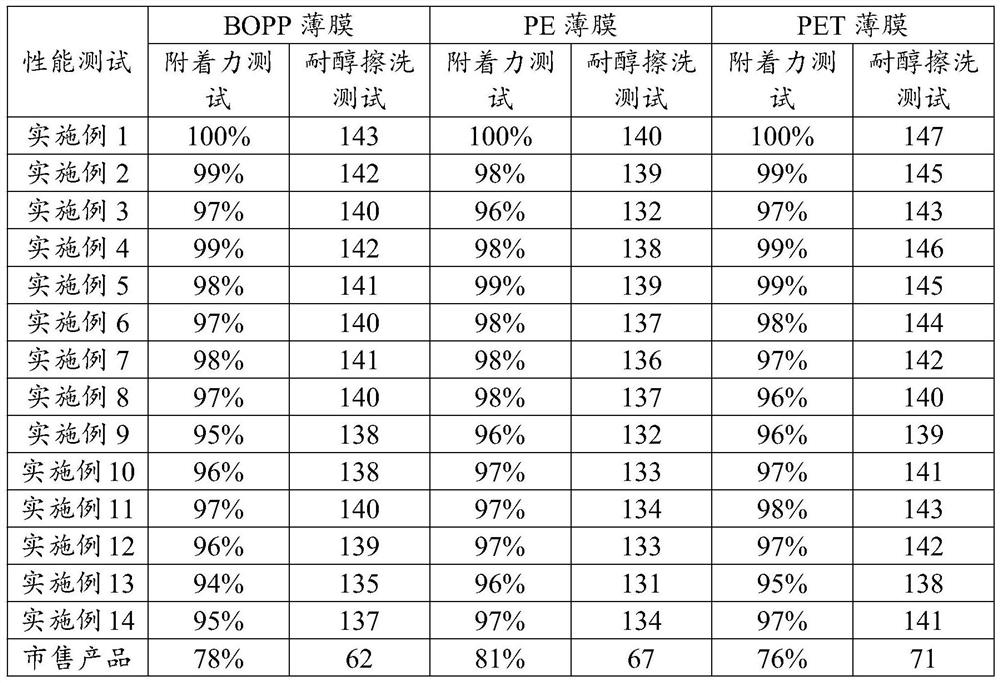

Examples

Embodiment 1

[0067] This embodiment provides a kind of high-adhesive emulsion used for cigarette pack film, which consists of the following raw materials in parts by weight:

[0068] Phase A: 320 parts of acrylic resin, 285 parts of deionized water, 30 parts of cationic emulsifier, and 20 parts of anionic emulsifier; among them, the cationic emulsifier is made of dodecyl chloride with a weight ratio of 1:1:1 A mixture of ammonium chloride, cetyltrimethylammonium bromide and cetylpyridinium bromide; the anionic emulsifier is a mixture of oleic acid soap and stearic acid in a weight ratio of 1:1:1:1 A mixture of sodium, fatty acid polyether sulfate and sodium alkylsulfonate.

[0069] Phase B: 3 parts of 1,6-hexanediol diacrylate, 10 parts of the first monomer composed of hydroxyethyl acrylate, 150 parts of the second monomer composed of butyl acrylate, composed of hydroxyethyl methacrylate 3 parts of the third monomer, 38 parts of the fourth monomer composed of butyl methacrylate, 144 parts...

Embodiment 2

[0088] In this example, on the basis of Example 1, the first monomer in Phase B is changed to be composed of propyl acrylate, and the rest is the same as Example 1.

Embodiment 3

[0090] In this example, on the basis of Example 1, the second monomer in phase B is changed to be composed of isooctyl acrylate, and the rest is the same as that of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com