Foaming agent compound for low-temperature decomposition of expanding rubber and preparation method of foaming agent compound

A technology of expanding rubber and foaming agent, which is applied in the field of composite material preparation, can solve the problems affecting the foaming height and sagging of expanding rubber, small gas generation, not paying attention to gas generation, decomposition rate, cell uniformity, surface roughness, etc. problem, to achieve the effect of uniform cell dispersion, high cost performance, smooth and delicate surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] This example provides a blowing agent compound for low-temperature decomposition of expanded rubber, including the following components: 5 μm AC foaming agent: 90 phr, OBSH foaming agent: 10 phr, zinc p-toluenesulfonate: 1 phr, Urea: 2 phr, Zinc Oxide: 5 phr, Zinc Carbonate: 5 phr, Zinc Stearate: 1 phr, Stearic Acid: 2 phr.

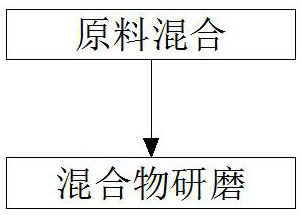

[0032] see figure 1 , its preparation method is as follows:

[0033] Step 1: Mix the ingredients

[0034] First, add AC foaming agent, OBSH foaming agent, zinc p-toluenesulfonate, urea, zinc oxide, zinc carbonate, zinc stearate, and stearic acid into the stirring equipment and stir and mix evenly to obtain a mixture for later use;

[0035] Step 2: Grinding the mixture

[0036] According to step 1, the uniformly mixed mixture is ground in stages by a grinder to prepare a foaming agent product and sealed for storage.

[0037] The foaming agent of this example was used as the foaming system for preparing EPDM foaming materials to prepare expansion...

Embodiment 2

[0039] This example provides a blowing agent compound for low-temperature decomposition of expanded rubber, including the following components: 5 μm AC foaming agent: 90 phr, OBSH foaming agent: 10 phr, zinc p-toluenesulfonate: 1 phr, Urea: 2 phr, Zinc Carbonate: 10 phr, Zinc Stearate: 1 phr, Stearic Acid: 2 phr.

[0040] see figure 1 , its preparation method is as follows:

[0041] Step 1: Mix the ingredients

[0042] First, add AC foaming agent, OBSH foaming agent, zinc p-toluenesulfonate, urea, zinc carbonate, zinc stearate, and stearic acid of the specified components into the stirring equipment and stir and mix evenly to obtain a mixture for later use;

[0043] Step 2: Grinding the mixture

[0044] According to step 1, the uniformly mixed mixture is ground in stages by a grinder to prepare a foaming agent product and sealed for storage.

[0045] The foaming agent of this example was used as the foaming system for preparing EPDM foaming materials to prepare expansion g...

Embodiment 3

[0047] This example provides a blowing agent compound for low-temperature decomposition of expanded rubber, including the following components: 2 μm AC foaming agent: 90 phr, OBSH foaming agent: 10 phr, zinc p-toluenesulfonate: 1 phr, Urea: 2 phr, Zinc Carbonate: 10 phr, Zinc Stearate: 1 phr, Stearic Acid: 2 phr.

[0048] see figure 1 , its preparation method is as follows:

[0049] Step 1: Mix the ingredients

[0050]First, add AC foaming agent, OBSH foaming agent, zinc p-toluenesulfonate, urea, zinc carbonate, zinc stearate, and stearic acid of the specified components into the stirring equipment and stir and mix evenly to obtain a mixture for later use;

[0051] Step 2: Grinding the mixture

[0052] According to step 1, the uniformly mixed mixture is ground in stages by a grinder to prepare a foaming agent product and sealed for storage.

[0053] The foaming agent of this example was used as the foaming system for preparing EPDM foaming materials to prepare expansion gl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com