Preparation method of high-strength centrifugal casting precoated sand

A centrifugal casting, high-strength technology, applied to casting molding equipment, casting molds, cores, etc., can solve the problems of low glass sand strength, difficult regeneration of old sand, waste of old sand, etc., to achieve simple preparation process and prevent sand sticking Defects, life-prolonging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

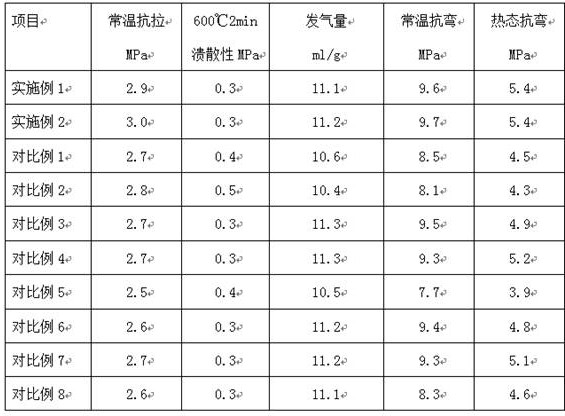

Examples

Embodiment 1

[0024]The first step, preparation of polyphosphazene derivatives: Under vacuum conditions, hexachlorocyclotriphosphazene was melt-polymerized at 250°C for 48 hours, washed with dry petroleum ether for 3 times after cooling, and dried in vacuum to obtain polydichlorophosphazene Take 69 parts of polydichlorophosphazene, dissolve in tetrahydrofuran, take 48 parts of 2,2,2-trifluoroethanol and 130 parts of 2,2,3,3-tetrafluoropropanol, and dissolve them in tetrahydrofuran with excess metal sodium React at room temperature until bubbles are no longer generated, weigh 28.8 parts of sodium hydride and 88 parts of p-hydroxybenzaldehyde in tetrahydrofuran for 12 hours at room temperature, and pour the sodium salt solution of trifluoroethanol and octafluoropentanol into poly In dichlorophosphazene solution, react at 30°C for 12h, then add 4-formaldehyde sodium phenoxide, reflux for 120h, precipitate the product in deionized water for 3 times, precipitate in petroleum ether twice, and dry ...

Embodiment 2

[0027] The first step, preparation of polyphosphazene derivatives: Under vacuum conditions, hexachlorocyclotriphosphazene was melt-polymerized at 240°C for 36 hours, washed twice with dry petroleum ether after cooling, and dried in vacuum to obtain polydichlorophosphazene Take 69 parts of polydichlorophosphazene, dissolve in tetrahydrofuran, take 54 parts of 2,2,2-trifluoroethanol and 125 parts of 2,2,3,3-tetrafluoropropanol, and dissolve excess metal sodium in tetrahydrofuran React at room temperature until bubbles are no longer generated, weigh 28.8 parts of sodium hydride and 88 parts of p-hydroxybenzaldehyde in tetrahydrofuran for 12 hours at room temperature, and pour the sodium salt solution of trifluoroethanol and octafluoropentanol into poly Dichlorophosphazene solution, reacted at 25°C for 8 hours, then added 4-formaldehyde sodium phenoxide, refluxed for 100 hours, precipitated the product twice in deionized water, twice in petroleum ether, and dried in vacuum for 24 h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com