Coated core sand for casting train steel casting and preparation method of coated core sand

A technology for steel castings and film coating, which is applied in the field of coated core sand for train steel castings and its preparation, can solve the problems of anti-sticking sand and anti-veining ability, poor heat resistance, and casting veining, etc. To achieve strong anti-stick sand and anti-veining ability, good heat resistance, reduce the effect of veining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] A film-coated core sand for train steel castings, which is prepared from the following raw materials in parts by weight (kg): mountain sand 170, zircon sand 30, corundum sand 20, pearl sand 15, white paste mud 15, phenolic resin 2. BT resin 2, 3-glycidyl ether oxypropylmethyldiethoxysilane 1, urotropine 0.6, rosin pentaerythritol ester 0.5, pyroclastic 5, quartz crucible waste 6, salt mud 2, para Tosyl chloride 0.3, bisbenzylamino ether 0.2, trioctyl trimellitate 1, bismuth oxide 3, ferronickel slag 4, ethanol 20.

[0015] A method for preparing film-coated core sand for train steel castings, comprising the following steps:

[0016] (1) Mix quartz crucible waste, volcanic debris and ferronickel slag evenly, crush them into 80-100 mesh size, and then mix them with mountain sand, zircon sand, corundum sand, pearl sand, white paste mud, salt mud, bismuth oxide Add them together to the sand mixer and dry mix for 4-5 minutes to obtain a mixture;

[0017] (2) Add phenolic r...

Embodiment 2

[0020] A film-coated core sand for train steel castings, which is prepared from the following raw materials in parts by weight (kg): mountain sand 175, zircon sand 35, corundum sand 25, pearl sand 17.5, white plaster mud 17.5, phenolic resin 3. BT resin 2.5, 3-glycidyl ether oxypropylmethyldiethoxysilane 1.5, urotropine 0.7, rosin pentaerythritol ester 0.6, pyroclastic 6, quartz crucible waste 7, salt mud 2.5, Tosyl chloride 0.4, bisbenzylamino ether 0.3, trioctyl trimellitate 1.5, bismuth oxide 4, ferronickel slag 5.5, ethanol 25.

[0021] The preparation method is the same as in Example 1.

Embodiment 3

[0023] A film-coated core sand for train steel castings, which is prepared from the following raw materials in parts by weight (kg): mountain sand 180, zircon sand 40, corundum sand 30, pearl sand 20, white paste mud 20, phenolic resin 4. BT resin 3, 3-glycidyl ether oxypropylmethyldiethoxysilane 2, urotropine 0.8, rosin pentaerythritol ester 0.7, pyroclastic 7, quartz crucible waste 8, salt mud 3, para Tosyl chloride 0.5, bisbenzylamino ether 0.4, trioctyl trimellitate 2, bismuth oxide 5, ferronickel slag 7, ethanol 30.

[0024] The preparation method is the same as in Example 1.

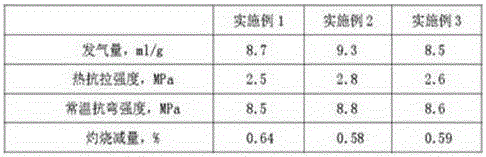

[0025] The performance testing result of the film-coated core sand for the train steel casting casting that above-mentioned embodiment 1-3 makes is shown in the table below:

[0026]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com