Calcium carbide acetylene production technology capable of reducing generation of calcium carbide slag

A calcium carbide acetylene and production process technology, which is applied in the field of coal chemical industry, can solve the problems of shortening the reaction time of solid calcium carbide, not considering the utilization of waste residue, and reducing the reaction temperature, so as to achieve efficient and clean production, improve the production efficiency of calcium carbide, and improve the quality of calcium carbide Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

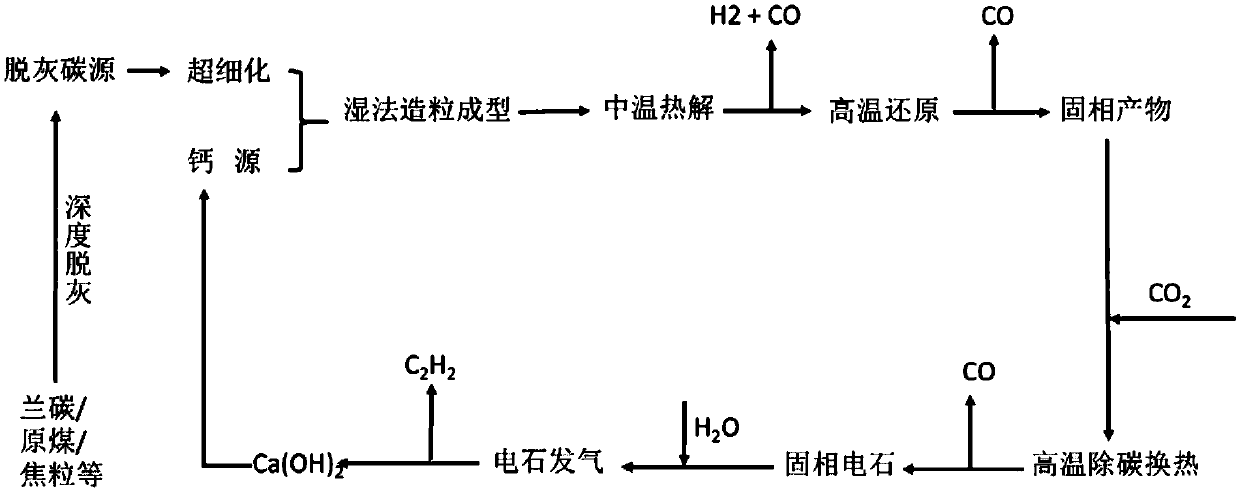

[0040] This embodiment is used to reduce the calcium carbide acetylene production process that carbide slag produces, combining figure 1 As shown, it specifically includes the following steps:

[0041] S1. Preparation materials: After deep deliming of coke from a factory with an ash content of 12.02wt% and a fixed carbon content of 70.03wt% in a micro-nano bubble deashing device in NaOH solution medium, the obtained ash content is 4.79wt%. Delimed coke with a fixed carbon content of 92.09wt% (as shown in Table 1); after mixing delimed coke with quicklime (purity not less than 99.0wt%) according to the carbon-calcium molar ratio of 2.7:1, perform ultrafine Prepare superfine mixture with particle size less than 100um;

[0042] S2. Wet granulation molding: mix the superfine mixture and water according to the mass ratio of 65:35, so that the calcium oxide is completely digested; the digested mixture is granulated in a disc granulator to obtain Cylindrical calcium carbide raw mat...

Embodiment 2

[0063] This embodiment is used to reduce the calcium carbide acetylene production process that carbide slag produces, combining figure 1 As shown, it specifically includes the following steps:

[0064] S1. Preparation of materials: After deep deliming of a factory coke with an ash content of 12.02wt% and a fixed carbon content of 70.03wt% in an ultrasonic device in a NaOH solution medium, the obtained ash content is 4.79wt%, and the fixed carbon content is 92.09wt% delimed coke; after mixing delimed coke and calcium hydroxide (purity not less than 99.0wt%) according to the carbon-calcium molar ratio of 2.7:1, then superfine to obtain a powder material with a particle size of less than 100um ;

[0065] S2. Wet granulation molding: mix the superfine mixture and kerosene evenly according to the mass ratio of 100:25, and then granulate in a disc granulator to obtain a spherical calcium carbide raw material group with a particle size of 1 cm;

[0066] S3. Calcium carbide synthesi...

Embodiment 3

[0074] The present embodiment is used to reduce the calcium carbide acetylene production process that carbide slag produces, specifically comprises the following steps:

[0075] S1. Preparation materials: After deep deliming of raw coal from a factory with an ash content of 10.73wt% and a fixed carbon content of 71.95wt% in a microwave-microbubble deashing device in NaOH solution medium, an ash content of 1.22wt% was obtained , deashed coal with a fixed carbon content of 81.84wt% (as shown in Table 2); after mixing deashed coal with calcite (calcium carbonate purity of 98.2wt%) according to the carbon-calcium molar ratio of 3.2:1, ultrafine Chemically prepare ultra-fine mixture with particle size less than 100um;

[0076] S2. Wet granulation molding: mix the superfine mixture and water evenly according to the mass ratio of 78:22, and then granulate in a disc granulator to obtain a spherical calcium carbide raw material group with a particle size of 0.75cm ;

[0077]S3. Calci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com