Efficient energy-saving humidification air purifier

A high-efficiency, energy-saving, humid air technology, applied in the field of air purification, can solve problems such as the inability of air to reach uniformly, the absence of disinfection and sterilization functions, and the impact on the quality of humidified air, and achieve the effects of simple structure, reduced power, and reasonable settings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

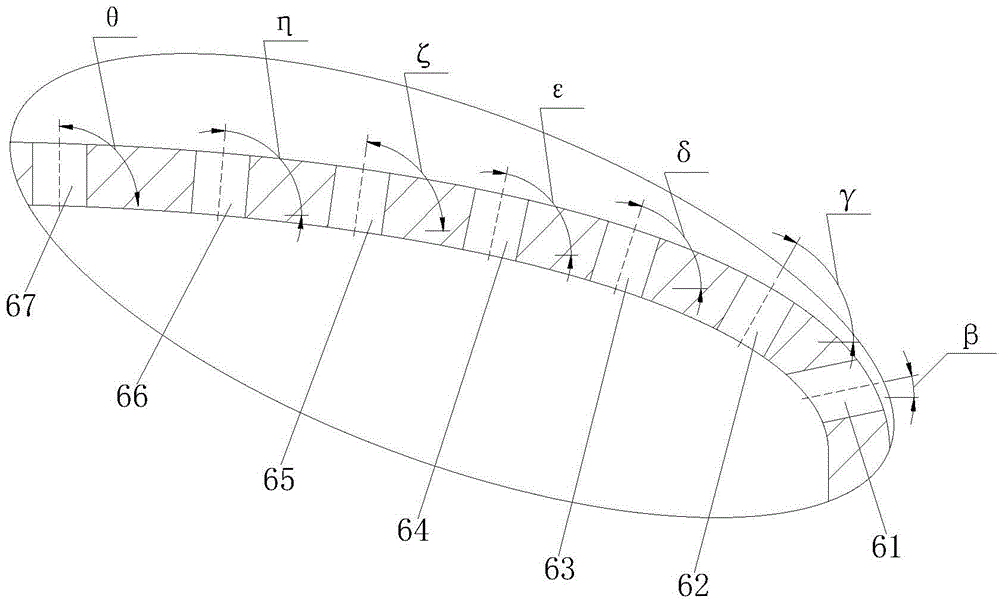

[0034] Equipped with 100kg of the filter core of the present invention, it is formulated from the following components: 13kg of water, 8kg of epoxy resin, 16kg of negative ion powder, 42kg of activated carbon powder, and 21kg of far-infrared powder; the filter core 7- The preparation technology of 2 comprises the following steps: a, the water of 13kg drops into the mixing tank, drops into the epoxy resin of 8kg, the negative ion powder of 16kg, the gac powder of 42kg and the far-infrared powder of 21kg successively in water, makes epoxy resin , Negative ion powder, activated carbon powder and far-infrared powder are evenly distributed in the water, the stirring speed is 700 rpm, and the stirring time is 5 minutes, and the dough is obtained at this time; b. Put the dough in step a into the predetermined mold, Then stamping and forming by a punching machine; c, put the stamped and formed block in step b into a drying oven for drying, the drying temperature is 100 degrees, and the...

example 2

[0036] Equipped with 100kg of the filter element of the present invention, which is prepared from the following components: 15kg of water, 5kg of epoxy resin, 20kg of negative ion powder, 40kg of activated carbon powder, and 20kg of far-infrared powder; the filter element 7- The preparation technology of 2 comprises the following steps: the water of a, 15kg drops into the mixing tank, drops into the epoxy resin of 5kg, the negative ion powder of 20kg, the gac powder of 40kg and the far-infrared powder of 20kg successively in water, makes epoxy resin , Negative ion powder, activated carbon powder and far-infrared powder are evenly distributed in the water, the stirring speed is 800 rpm, and the stirring time is 6 minutes, and the dough is obtained at this time; b. Put the dough in step a into the predetermined mold, Then stamping and forming by a punching machine; c, put the stamped and formed block in step b into a drying oven for drying, the drying temperature is 120 degrees, ...

example 3

[0038] Equipped with a 100kg filter core of the present invention, which is prepared from the following components: 10kg of water, 7kg of epoxy resin, 10kg of negative ion powder, 49kg of activated carbon powder, and 24kg of far-infrared powder; the filter core 7- The preparation technology of 2 comprises the following steps: a, the water of 10kg drops into the mixing tank, drops into the epoxy resin of 7kg, the anion powder of 10kg, the gac powder of 49kg and the far-infrared powder of 24kg successively in water, makes epoxy resin , Negative ion powder, activated carbon powder and far-infrared powder are evenly distributed in the water, the stirring speed is 650 rpm, and the stirring time is 7 minutes, and the dough is obtained at this time; b. Put the dough in step a into the predetermined mold, Then stamping and forming by a punching machine; c, put the stamped and formed block in step b into a drying oven for drying, the drying temperature is 120 degrees, and the drying tim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com