A method for strengthening soft soil foundation by temperature-increasing vacuum preloading method

A technology of vacuum preloading and soft soil foundation, applied in soil protection, infrastructure engineering, construction, etc., can solve the problems of uneven settlement, large settlement after construction, small maximum preloading load, etc., and achieve the speed of water vapor diffusion. Fast, improve the bearing capacity of the foundation, the effect of high soil compaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

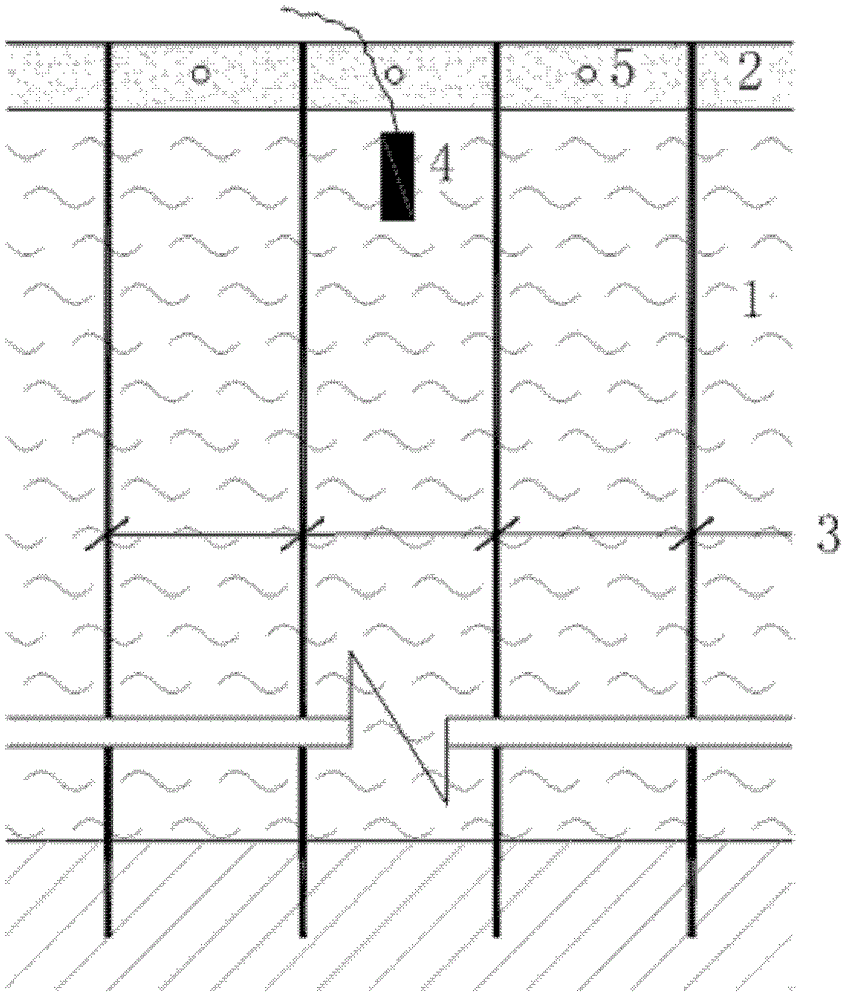

[0033] A temperature-increasing vacuum preloading method for strengthening soft soil foundations. This method introduces a foundation heating system on the basis of conventional vacuum preloading methods. The temperature is maintained above 80kPa and 62°C, so that the pore water of the foundation soil is vaporized rapidly, and is drawn out by the vacuum equipment, and the foundation subsides.

[0034] The above-mentioned foundation heating system adopts the method of "point heating". Specifically, electric heating rods are inserted in the foundation. The insertion depth requires that the electric heating rods enter a certain depth in the soft soil layer. The plane layout can be evenly arranged in a plum blossom shape or a square , the spacing should be determined according to the thermal conductivity of the foundation soil, the rated power of the electric heating rod and other conditions. During construction in summer, the layout or number of electric heating rods can be adjus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com