Silt-cement light building block, method for preparing same and application of silt-cement light building block

A cement and block technology, which is applied in the field of silt-cement lightweight blocks and their preparation, can solve the problems of large drying shrinkage, cracking or settlement, and easy cracking of the silt solidified body, so as to be beneficial to environmental protection and reduce waste. The effect of uniform settlement and improved adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

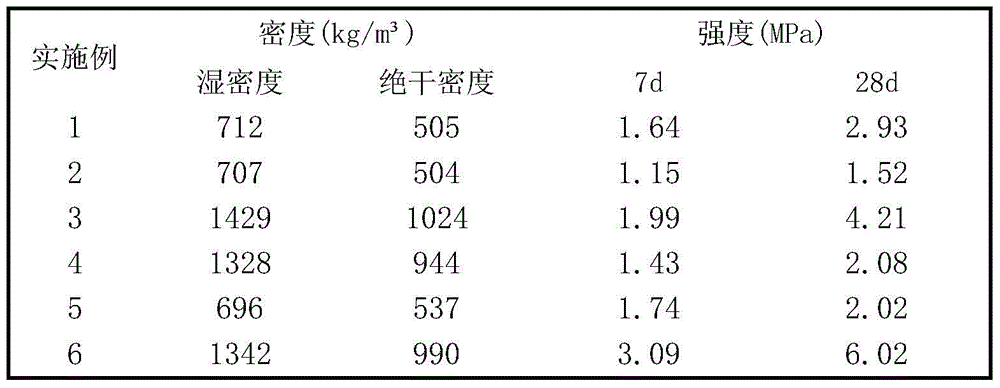

Embodiment 1

[0061] A silt-cement lightweight building block is composed of the following raw materials in weight percentages: 56 parts of cement, 17 parts of fly ash, 15 parts of silt, 3.6 parts of an air-generating agent, 1.2 parts of a foam-stabilizing agent, and the activator is 6% of the weight of the aerosol.

[0062] Preparation method: Weigh a certain amount of air-dried and sieved silt, add water to make it reach saturated moisture content, stir evenly and let it stand for more than 6 hours; weigh a certain amount of cement, fly ash and calcium stearate, pour Put into the mixer and stir slowly for 30s, weigh a certain amount of water and ferric chloride, add ferric chloride into the water first, pour the ferric chloride solution into the mixer and stir slowly for 30s; weigh a certain amount of saturated silt and add it to the mixer and stir slowly for 30s , Stir quickly for 90s; weigh a certain amount of hydrogen peroxide and pour it into the mixer for 15s-20s, quickly cast the mo...

Embodiment 2

[0064] A silt-cement lightweight building block, which is composed of the following raw materials in weight percentage: 51 parts of cement, 19 parts of fly ash, 28 parts of silt, 1.2 parts of an air generating agent, 1.2 parts of a foam stabilizer, and the activator is 6% of the weight of the aerosol.

[0065] Preparation method: Weigh a certain amount of air-dried and sieved silt, add water to make it reach saturated moisture content, stir evenly and let it stand for more than 6 hours; weigh a certain amount of cement, fly ash and calcium stearate, pour Put into the mixer and stir slowly for 30s, weigh a certain amount of water and ferric chloride, add ferric chloride into the water first, pour the ferric chloride solution into the mixer and stir slowly for 30s; weigh a certain amount of saturated silt and add it to the mixer and stir slowly for 30s , Stir quickly for 90s; weigh a certain amount of hydrogen peroxide and pour it into the mixer for 15s-20s, quickly cast the mol...

Embodiment 3

[0067] A silt-cement lightweight building block is composed of the following raw materials in weight percentage: 27 parts of cement, 18 parts of fly ash, 53 parts of silt, 1 part of gas-generating agent, 1.2 parts of foam-stabilizing agent, and the stimulating agent is 6% of the weight of the aerosol.

[0068] Preparation method: Weigh a certain amount of air-dried and sieved silt, add water to make it reach saturated moisture content, stir evenly and let it stand for more than 6 hours; weigh a certain amount of cement, fly ash and calcium stearate, pour Put into the mixer and stir slowly for 30s, weigh a certain amount of water and ferric chloride, add ferric chloride into the water first, pour the ferric chloride solution into the mixer and stir slowly for 30s; weigh a certain amount of saturated silt and add it to the mixer and stir slowly for 30s , Stir quickly for 90s; weigh a certain amount of hydrogen peroxide and pour it into the mixer for 15s-20s, quickly cast the mol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive modulus | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com