Pipe laying method for subsidence area of coal mine

A technology for pipeline laying and subsidence areas, which is applied in pipeline laying and maintenance, mechanical equipment, pipes/pipe joints/fittings, etc. It can solve problems such as cracking, breaking, and affecting the normal use of pipelines, so as to achieve complete functions, reduce additional stress, Guarantee the effect of normal operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

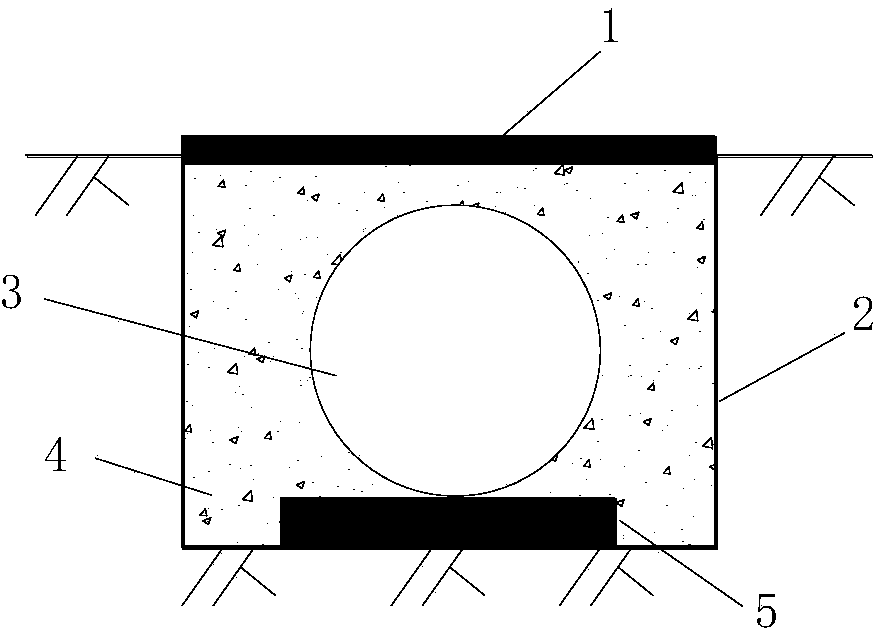

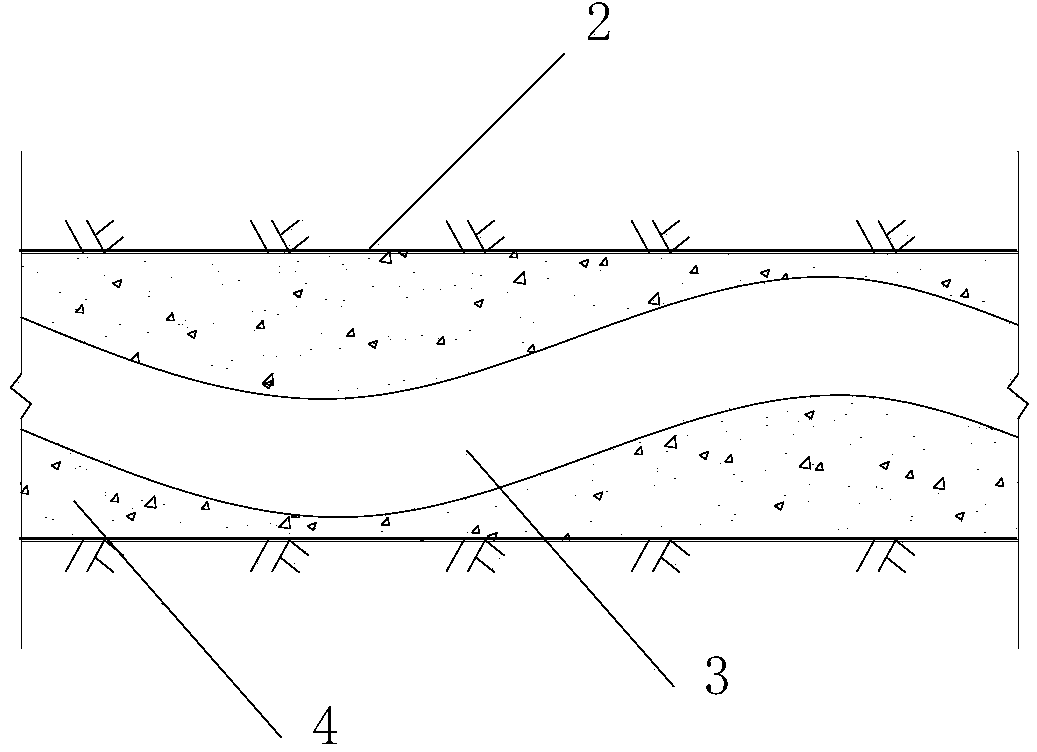

[0015] as attached figure 1 As shown, in order to avoid the direct effect of surface deformation on the pipeline structure, a cover plate trench is set in the subsidence area of the coal mine. The width of the trench is about 1m larger than the outer diameter of the laid pipeline, and the top of the trench is covered with a reinforced concrete cover with a thickness of about 5cm. During construction, a pipe ditch 2 is first excavated in the subsidence area, and a cover plate 1 is installed on the pipe ditch 2. A piece of rubber support 5 with a thickness of about 20 cm, then place the pipe 3 in the pipe trench 2, and backfill it with flexible buffer material 4 around it. In order to compensate the tensile or compressive effects of the horizontal deformation of the ground surface on the pipeline 3, the pipeline 3 is placed in the trench 2 in the shape of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com