Casting blank heat treatment method of stainless steel welding strip for nuclear power

A heat treatment method and stainless steel technology, which are applied in the field of heat treatment of stainless steel welding strips for nuclear power, can solve the problems of inability to form through hot rolling, increasing the tendency of austenitic stainless steel to process cracks, and stainless steel edge cracks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

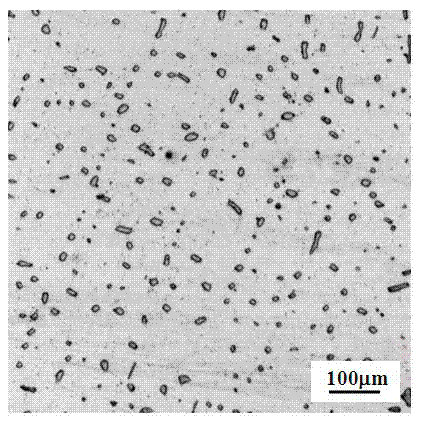

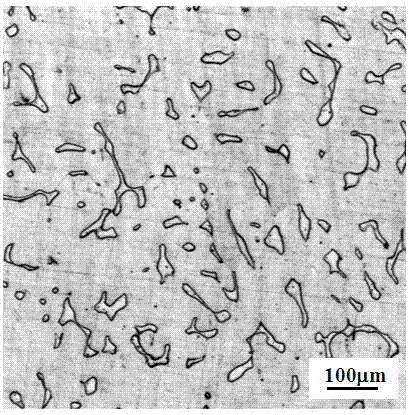

Image

Examples

Embodiment

[0020] Embodiment: This embodiment is a billet heat treatment method for effectively controlling hot-rolled edge cracks of stainless steel welding strips for nuclear power. The method includes the following steps:

[0021] ① After the surface of the continuous casting slab is ground, it is sent to the trolley-type high-temperature annealing furnace;

[0022] ② Heat the continuous casting slab to the desired temperature in the high-temperature annealing furnace, the temperature range is between 1100°C and 1200°C, and the heating rate is 50-100°C / h;

[0023] ③ The continuous casting slab is kept at the desired temperature described in ②, and the holding time is 60 to 240 minutes;

[0024] ④ After step ③ is completed, the continuous casting slab is cooled to room temperature in the air;

[0025] ⑤ The air-cooled continuous casting slab is sent to the walking heating furnace, and hot-rolled after soaking;

[0026] ⑥ After the above-mentioned heat treatment steps of the cast slab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com