Cantilever hanging bracket and using method thereof

A technology of cantilever cranes and trusses, which is applied in the field of bridge building construction devices, can solve the problems that hanging baskets and cantilever hangers cannot be used in common use, high construction costs, and safety cannot be guaranteed, and achieve reasonable force and high bearing capacity. High, low center of gravity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Now in conjunction with accompanying drawing, the present invention is described in further detail:

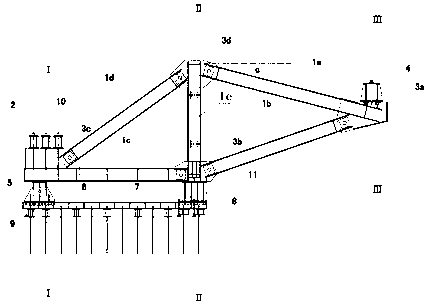

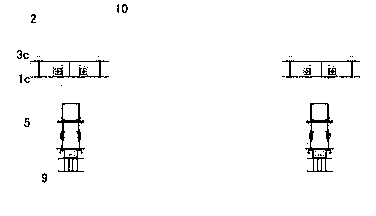

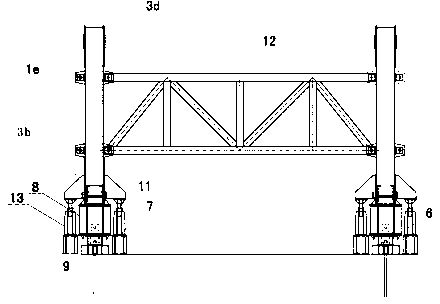

[0029] Such as figure 1 , figure 2 , image 3 with Figure 4 The shown cantilever hanger includes a main truss, a traveling mechanism arranged at the bottom of the main truss, and an anchoring device arranged at the rear end of the main truss; the main truss includes two symmetrically arranged diamond-shaped trusses, and the diamond-shaped truss includes an upper chord 1a, lower chord 1c, front chord 1b, rear chord 1d, front node 3a, rear node 3c, upper node 3d and lower node 3b, upper chord 1a, lower chord 1c, front chord 1b and rear chord 1d respectively It is welded by steel plates, and the front node 3a, the rear node 3c, the upper node 3d and the lower node 3b are respectively welded by steel plates. The front end of the upper chord 1a is connected with the upper end of the front chord 1b with a pin through the front node 3a, the rear end of the upper chord 1a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com