High-speed-railway karst roadbed structure with pre-warning function and repairing method thereof

A technology for high-speed railways and roadbeds, applied in infrastructure engineering, roads, roads, etc., can solve the problems of inaccurate positioning of karst caves, poor reinforcement effect, difficulty in secondary repair, etc., achieving light weight, easy construction, and high self-strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below through specific embodiments in conjunction with the accompanying drawings.

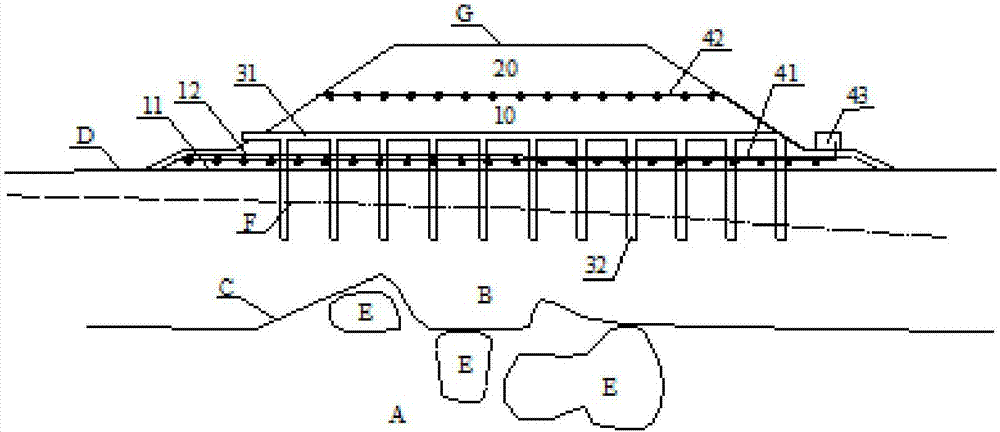

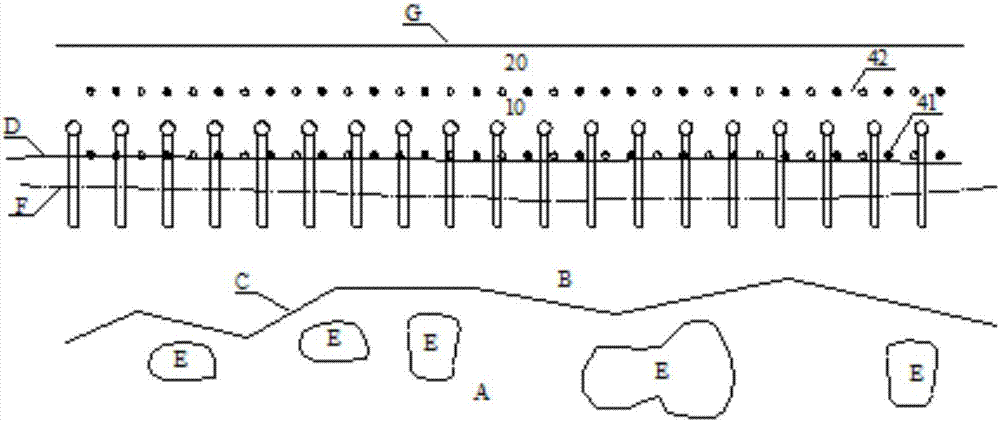

[0016] refer to figure 1 and figure 2 , a high-speed railway karst subgrade structure with early warning function of the present invention includes a high-strength geotextile isolation layer 11, a lightweight concrete filling body 10 and a foundation bed 20, the first high-strength geotextile isolation layer 11 is laid on the foundation, and the lightweight The concrete filling body 10 is filled on the first high-strength geotextile isolation layer 11 , and the foundation bed 20 is filled on the lightweight concrete filling body 10 . The lightweight concrete layer 10 is arranged below the subgrade bed 20 to replace the traditional subgrade filler, which not only greatly reduces the additional stress on the foundation caused by the train and the overlying fill soil, but also acts as a load bearing on the upper subgrade, greatly reducing th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com