Vacuum combined surcharge preloading construction method applied to soft soil foundation treatment

A technology of combined stacking and soft soil foundation, applied in the fields of soil protection, infrastructure engineering, on-site foundation soil survey, etc. problems, to achieve the effect of eliminating late settlement, shortening loading time, and reducing construction electricity consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

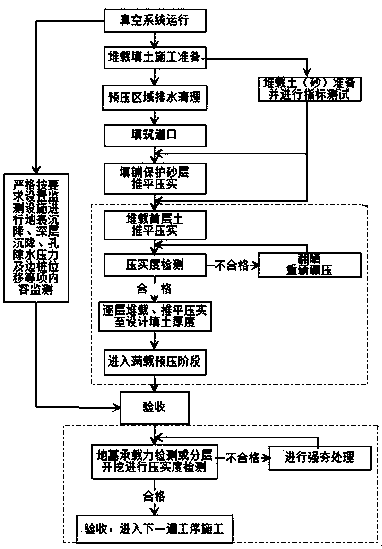

[0019] Such as figure 1 Shown: a vacuum combined surcharge preloading construction method applied to soft soil foundation treatment, including loading methods, monitoring methods and post-construction disposal methods;

[0020] The specific steps of the loading method are: a. In the early stage of the operation of the vacuum system in the preloading area, the vacuum degree must reach more than 80 kPa, and the pressure should be stabilized for 10 to 15 days. Covering the sealing film protective layer, the sealing film protective layer is non-woven geotextile;

[0021] b. Filling the crossing: when carrying out surcharge operations in the preloading area, cross the clay seal wall with relatively weak strength in the sealing area, fill the crossing with medium-coarse sand, the thickness is not less than 1.0m, and the surface is paved with steel plates with a thickness of not less than 20mm. Set crossings symmetrically on both sides of each sealed area, every 4000-5000m 2 set up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com