Thick slurry stirring chemical combination bucket

A technology of combining barrels and thick slurry, which is applied to mixers, mixers, chemical instruments and methods with rotary stirring devices, etc., can solve the problems of easy blocking of material settlement, large power consumption for stirring, blocking and stirring, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Now in conjunction with accompanying drawing, the present invention is described in further detail.

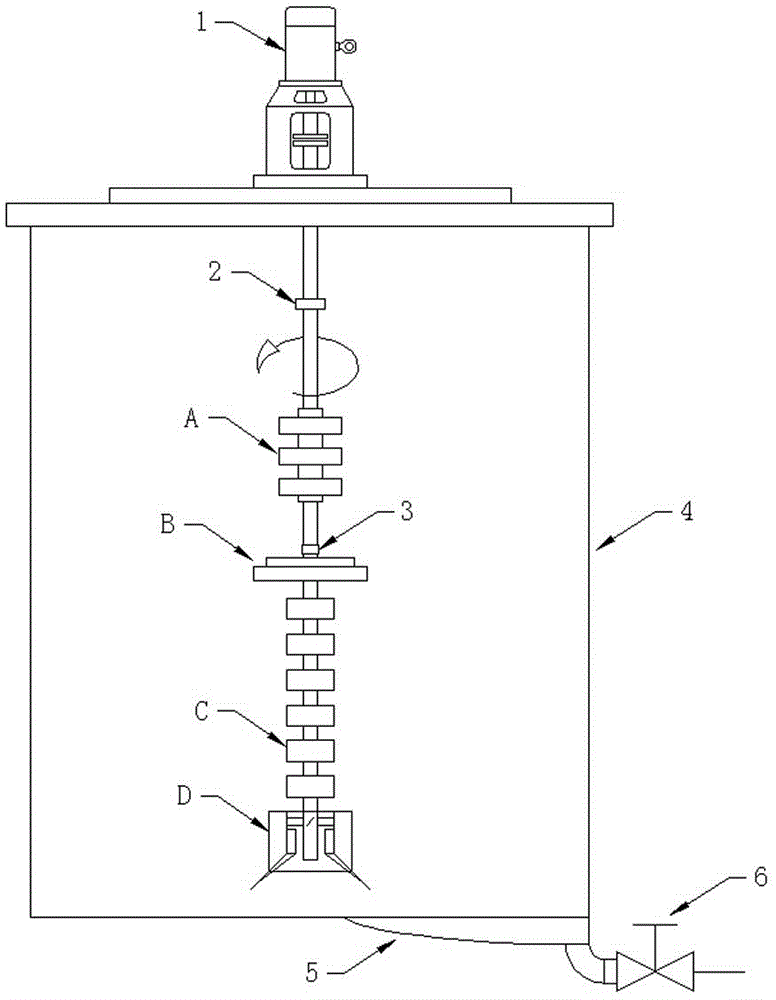

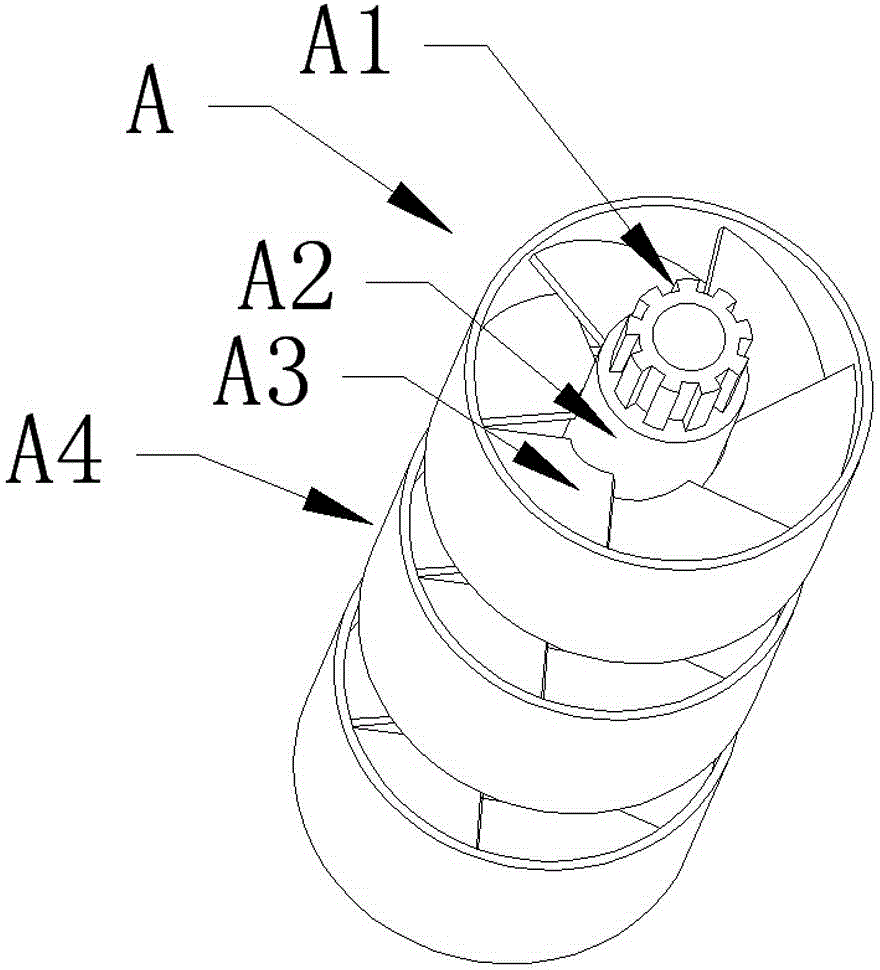

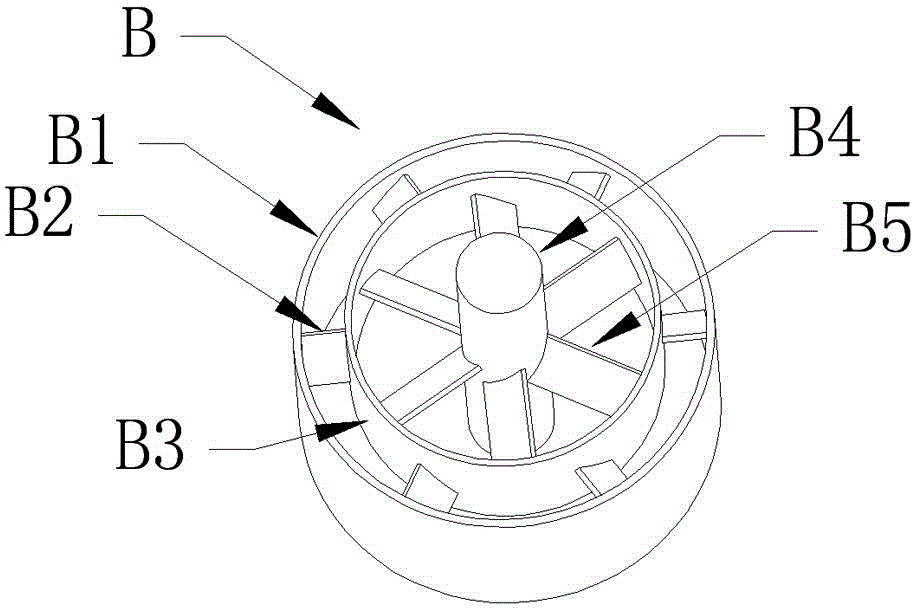

[0031] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 with Figure 7 The thick slurry mixing tank shown in the figure includes a tank body 4, a motor and a reducer 1, and a stirring shaft. The stirring shaft is inserted into the tank body 4, and the motor and reducer 1 drive the stirring shaft to rotate. The stirring shaft is bottom-sweeping from bottom to top Stirrer D, multi-stage series lower jet agitator C, two-way jet agitator B and suspended lower jet agitator A, wherein the suspended lower jet agitator A is limited by upper 2 and lower positioning steps 3 and can float up and down.

[0032] The bottom-sweeping agitator D includes a stirring shaft D7, an inner cylinder D5 and an outer cylinder D1, the stirring shaft D7 and the inner cylinder D5 are welded together through the axial flow blade D6, and the inner cylinder D5 extends...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com