Method for consolidating hydraulically-filled soft clay in hydraulic filling process by using vacuum preloading method

A vacuum preloading method and soft clay technology, applied in soil protection, infrastructure engineering, construction, etc., can solve the problems of reducing soft clay filling by dredging, not easy to ensure quality, and reducing compressibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

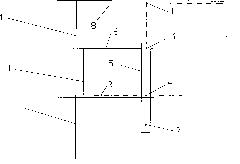

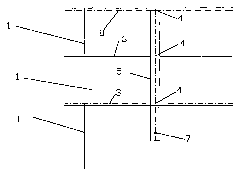

[0011] The present invention will be described in detail below in conjunction with accompanying drawing: As shown in the accompanying drawing, the method for carrying out the vacuum preloading method of the present invention to reinforce the blown soft clay in the process of blown soft clay is: Manually insert a 4-5m long drainage board 1 into the clay (if any) or blow-filled soft clay, and connect it with the drainage system. The drainage system is connected with the permeable pipe 5, and then blow-fill can be carried out on the soft clay For soft clay, when the required thickness is reached, another layer of drainage system shall be constructed.

[0012] The drainage system of the present invention comprises a horizontal drainage board connected with the upper end of the drainage board and a main drainage board connected with the horizontal drainage board, and the main drainage board is connected with the permeable pipe.

[0013] The upper end of the drainage board 1 shown i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com