Concentrated eight-treasure porridge slurry stirring and cooking pot

A technology for cooking pots and eight-treasure porridge, which is applied to mixers with rotating stirring devices, dissolving machines, mixers, etc., which can solve problems such as easy coking, material sedimentation, easy jamming, and stuck stirring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Now in conjunction with accompanying drawing, the present invention is described in further detail.

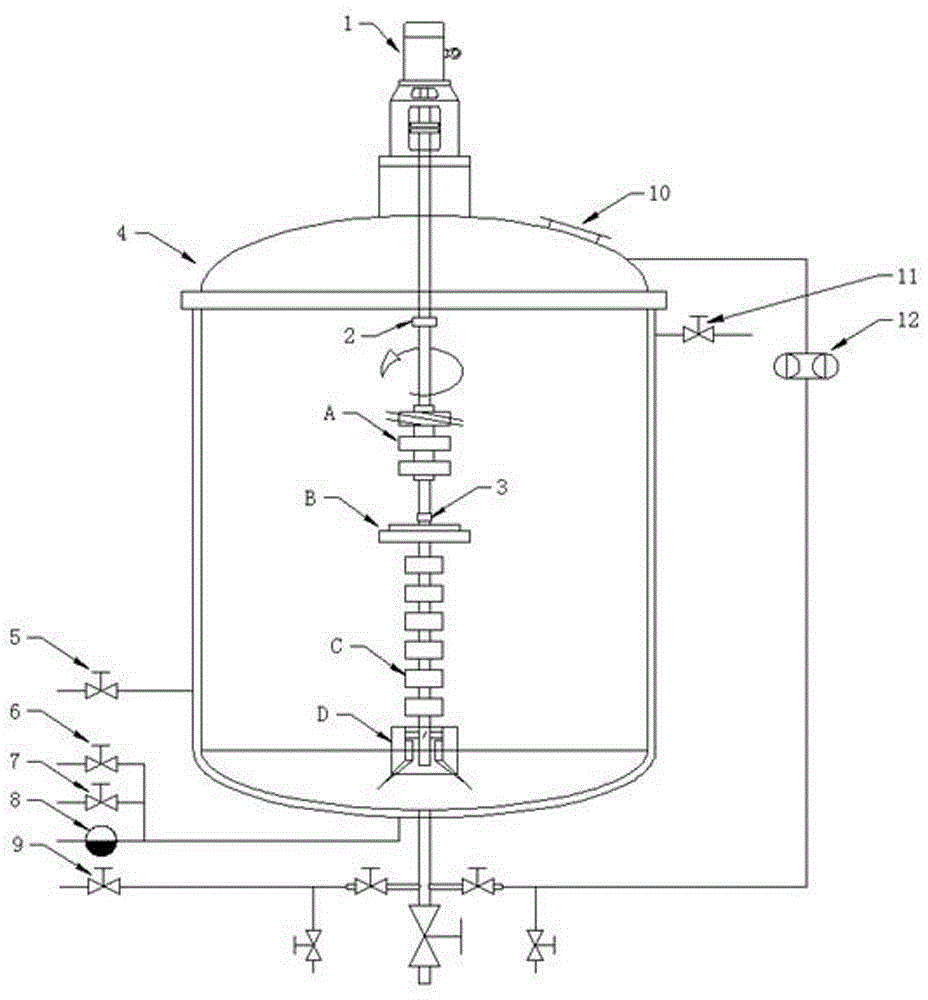

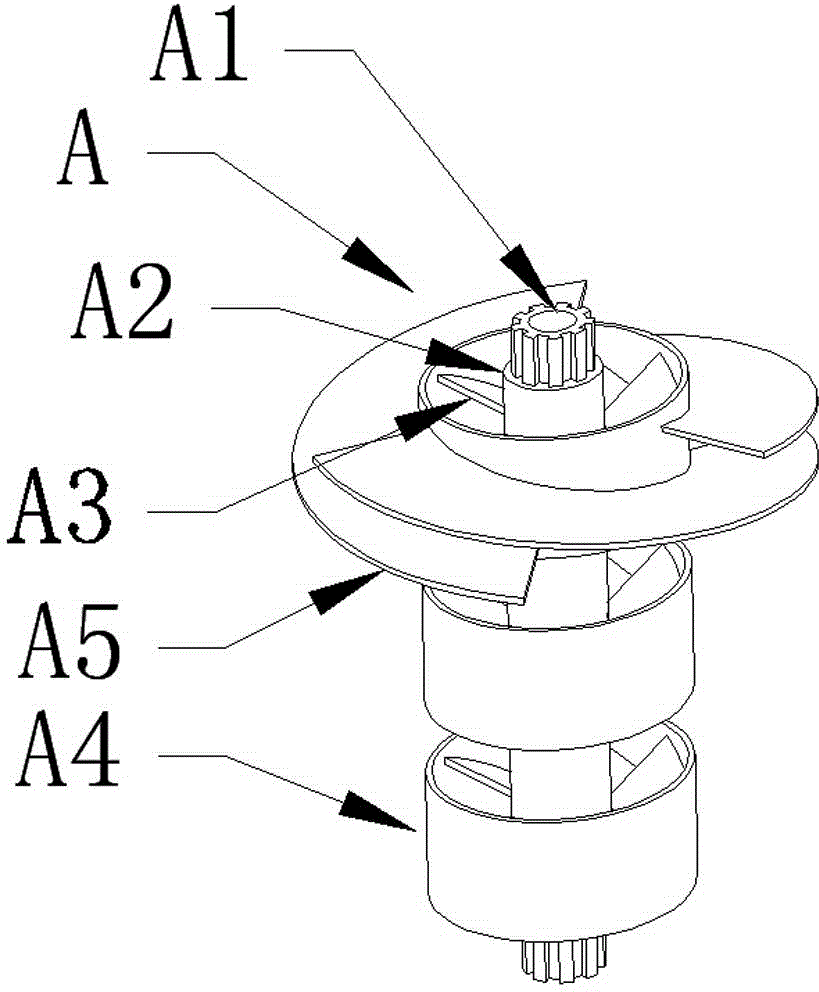

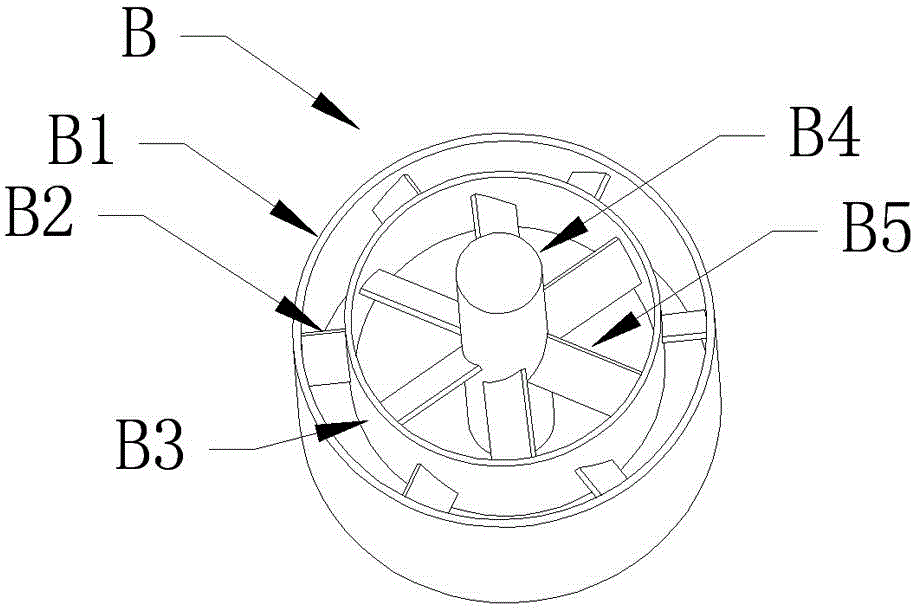

[0032] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 and Figure 7 The mixing and cooking tank for thick rice pudding shown in the figure includes a tank body 4, a motor, a reducer 1, and a stirring shaft. The stirring shaft is inserted into the tank body 4, and the motor and reducer 1 drive the stirring shaft to rotate. Bottom agitator D, multi-stage serial lower jet agitator C, two-way jet agitator B and suspended lower jet agitator A, wherein suspended lower jet agitator A is limited by upper 2 and lower positioning steps 3 and can float up and down; The tank body 4 is provided with a jacket, the jacket is connected with the steam valve 5, the drain valve 8 and the direct discharge valve 7, and the jacket is also connected with the water inlet valve 6 and the return pipe control valve 11; the bottom of the tank body 4 is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com