Energy-saving type treatment device for MBR (membrane biological reactor) oxidation ditch sewage

A sewage treatment device and oxidation ditch technology, applied in the field of biological technology treatment of sewage, can solve the problems of single aeration method, shallow water depth in the pool, low oxygenation efficiency, etc. The effect of nitrogen efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

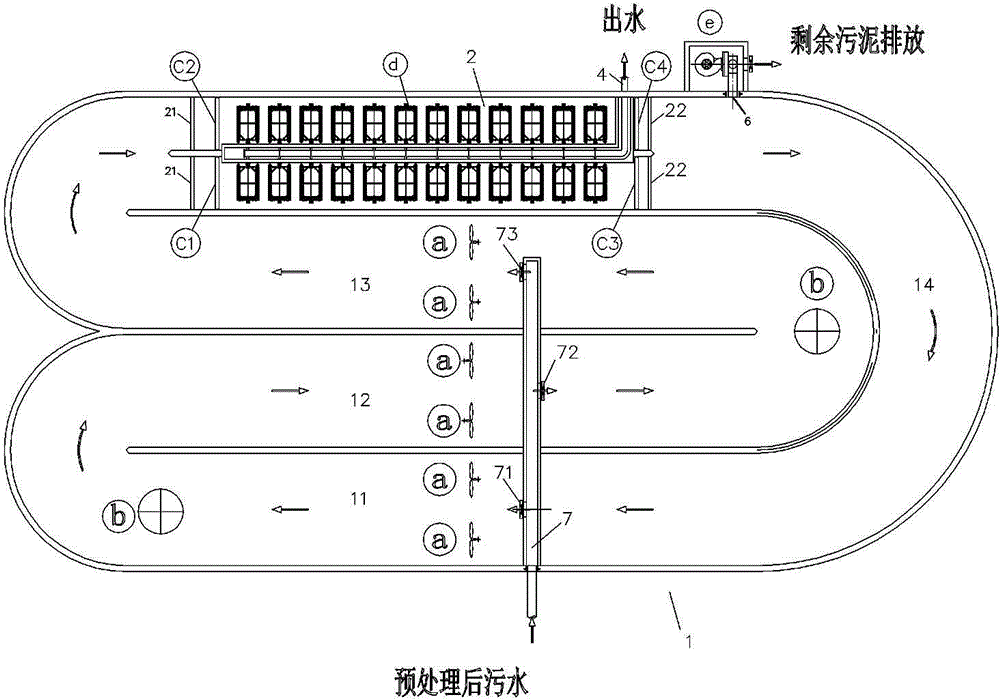

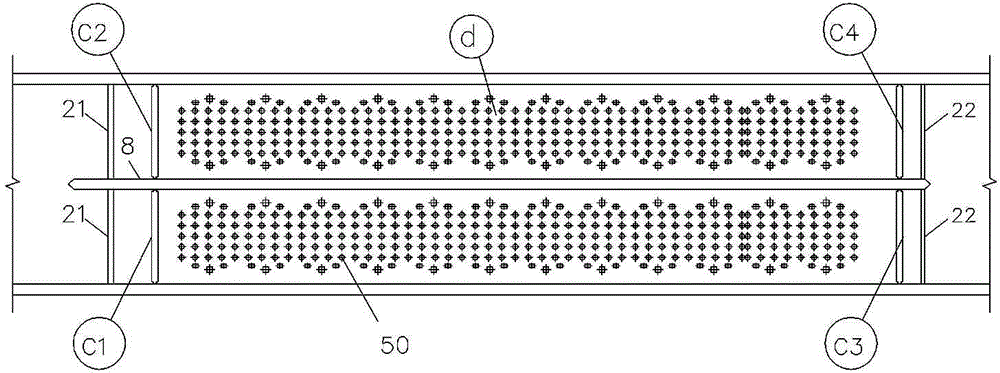

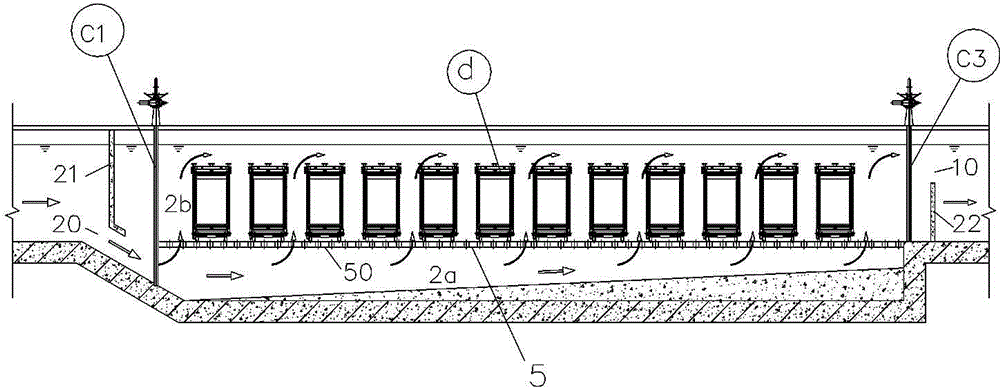

[0032] refer to figure 1 , figure 2 , image 3, an energy-saving MBR oxidation ditch sewage treatment device, including an oxidation ditch biochemical reaction zone 1 and a membrane zone 2, the oxidation ditch biochemical reaction zone 1 is an S-shaped corridor, the membrane zone 2 is a straight corridor, and the straight corridor of the membrane zone 2 The first straight corridor 11, the second straight corridor 12 and the third straight corridor 11 are arranged side by side and adjacent to each other in the oxidation ditch biochemical reaction zone 1. Corridors 13 are connected with each other by small arc corridors, and the third straight corridor 13 is adjacent to the membrane area 2 side by side, and the third straight corridor 13 ends are connected with one end of the membrane area 2 through the small arc corridors, and the membrane area The other end of 2 is connected with the first straight corridor 11 end by large arc corridor 14.

[0033] Both ends of the membran...

Embodiment 2

[0051] The difference between this embodiment and the first embodiment is that the partition plate 8, the front right gate c1, the front left gate c2, the rear right gate c3, and the rear left gate c4 are eliminated.

[0052] In this embodiment, online continuous cleaning of the membrane module cannot be realized, and there is no operation of the front right gate c1, front left gate c2, rear right gate c3, and rear left gate c4 during operation, and other operations are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com