Construction method of collaborative backfill of hydraulic dynamic compaction machine and flat plate roadpacker

A construction method and technology of a dynamic compactor, which are applied in soil protection, infrastructure engineering, construction, etc., can solve problems such as low construction efficiency, limited ramming energy, uneven settlement, etc., to improve construction efficiency and compaction. Speed, movement and flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to enable those skilled in the art to better understand, the technical solution of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

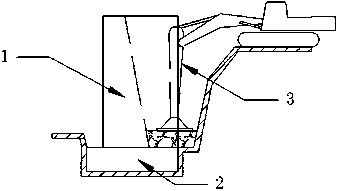

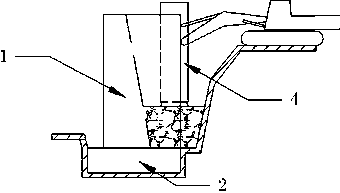

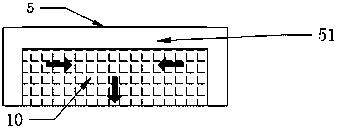

[0040] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 The construction method shown is a cooperative backfilling of hydraulic compaction machine and plate compaction machine. Before construction, one should carefully familiarize himself with the construction drawings and relevant technical materials, select the filler that meets the design requirements, and determine its optimal moisture content and CBR value. The operations are carried out in accordance with the relevant requirements of "Code for Construction and Quality Acceptance of Urban Road Engineering" (CJJ1), "Code for Construction and Quality Acceptance of Urban Bridge Engineering" (CJJ2), and this construction method will not be elaborated.

[0041] The cons...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com