Film plating device

A technology of a coating device and a coating umbrella, which is applied in sputtering coating, ion implantation coating, vacuum evaporation coating and other directions, can solve the problems of reducing coating precision, tilting of coating umbrella frame, difficult to adjust the horizontal position, etc. Accuracy, effect of avoiding differences in coating thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

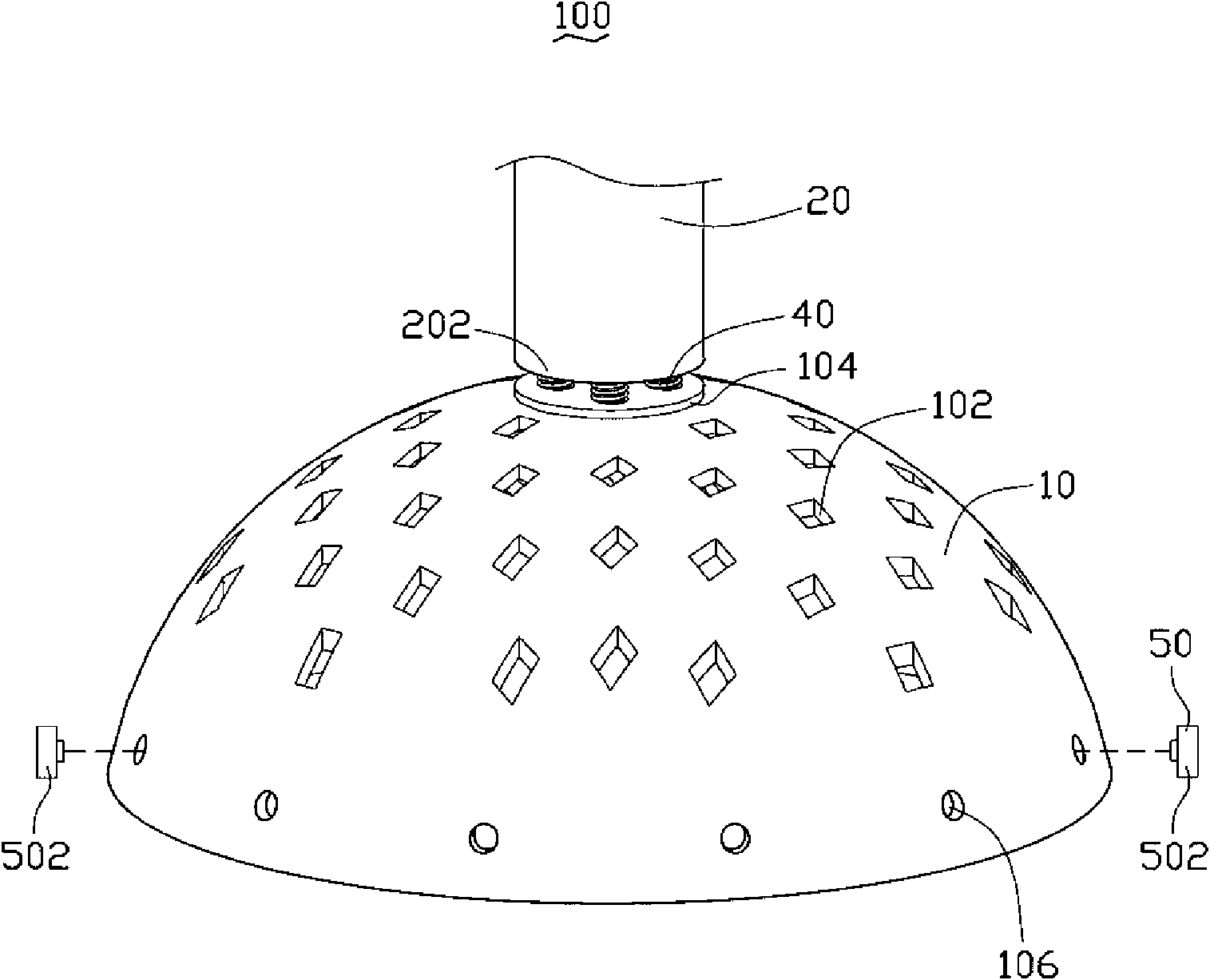

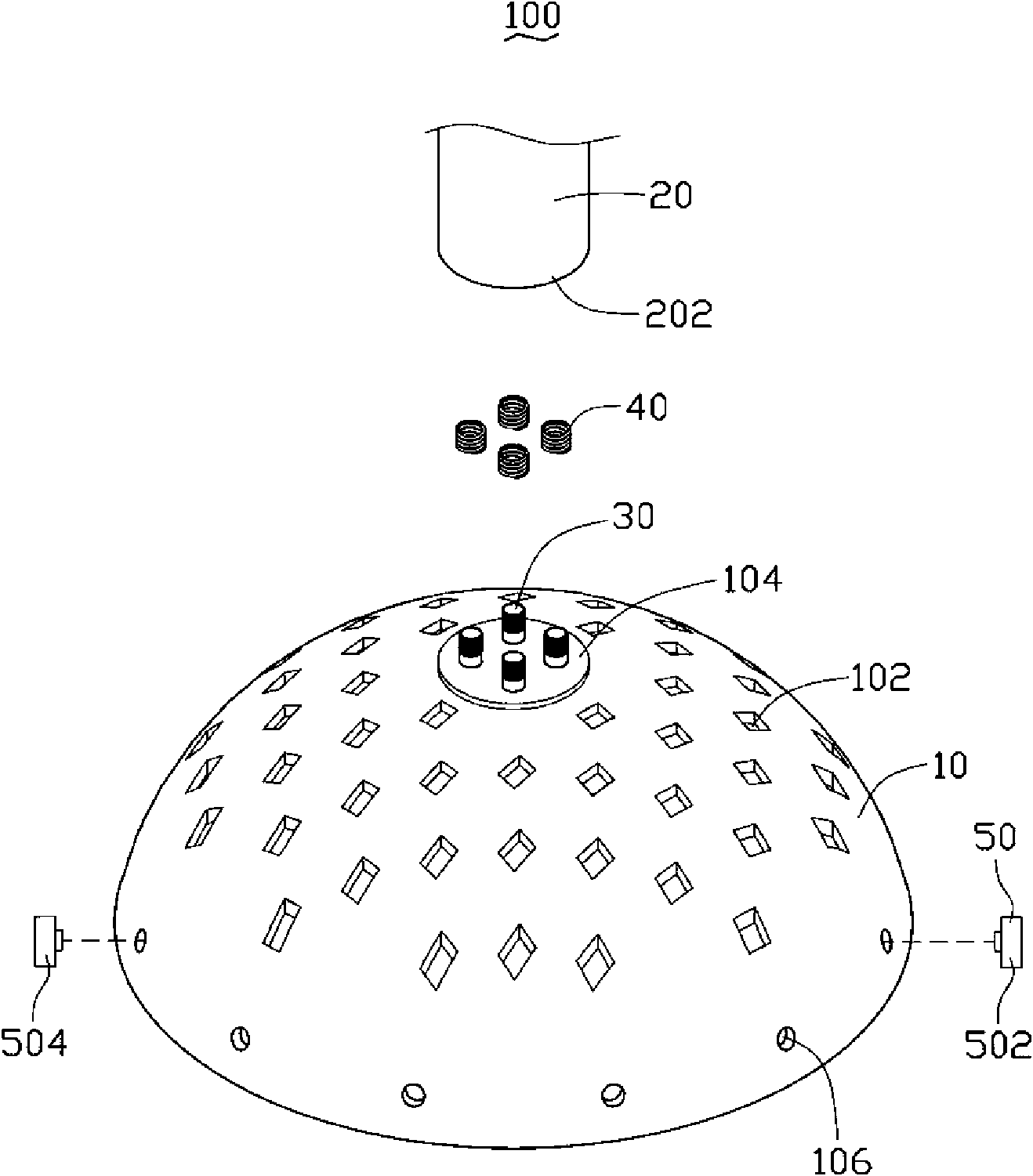

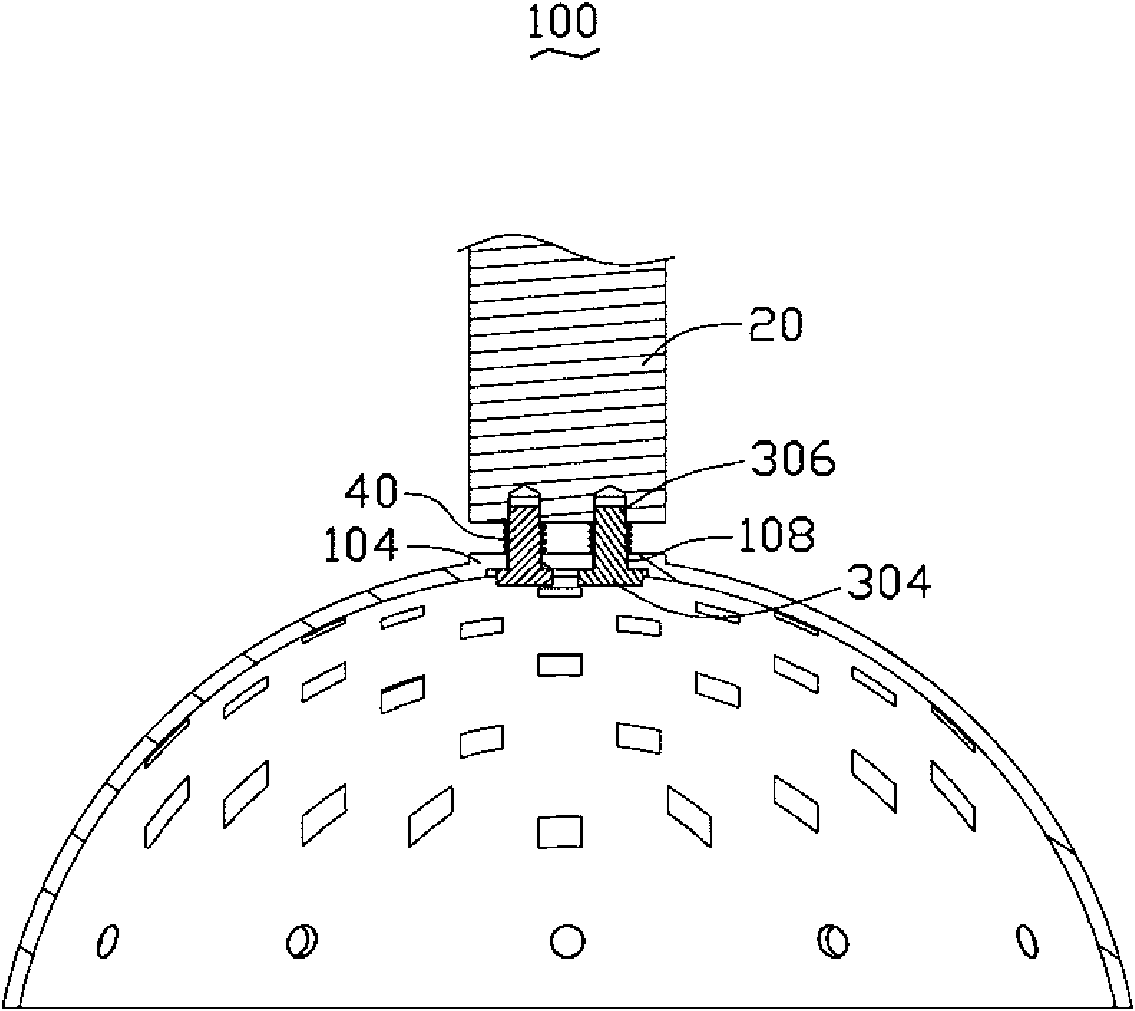

[0014] Please also refer to Figure 1 to Figure 3 , a coating device 100 provided in the first embodiment of the present invention. The coating device 100 includes a coating umbrella frame 10 , a bracket 20 , four connecting pieces 30 , four elastic elements 40 , and a detection device 50 .

[0015] The coated umbrella stand 10 is made of metal with good thermal conductivity, and its material can be metal such as copper, aluminum or stainless steel. The coating umbrella stand 10 is provided with a plurality of accommodating through holes 102 for accommodating workpieces to be coated (not shown). Twelve first through holes 106 are opened at the bottom of the coated umbrella stand 10 . Wherein, every two first through holes 106 are arranged oppositely and located on the same horizontal line. Preferably, the line connecting every two first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com