Liquid injection method and fixture for a square lithium-ion battery

A lithium-ion battery and liquid injection technology, which is applied to battery pack parts, circuits, electrical components, etc., can solve problems such as the inability to guarantee the amount of battery liquid injection, the stability of the unfavorable environment, and the battery thickness exceeding the standard, so as to avoid appearance wear, The effect of improving the qualified rate and utilization rate of batteries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] In the above-mentioned liquid injection method, it is necessary to use a clamp to clamp the prismatic lithium battery.

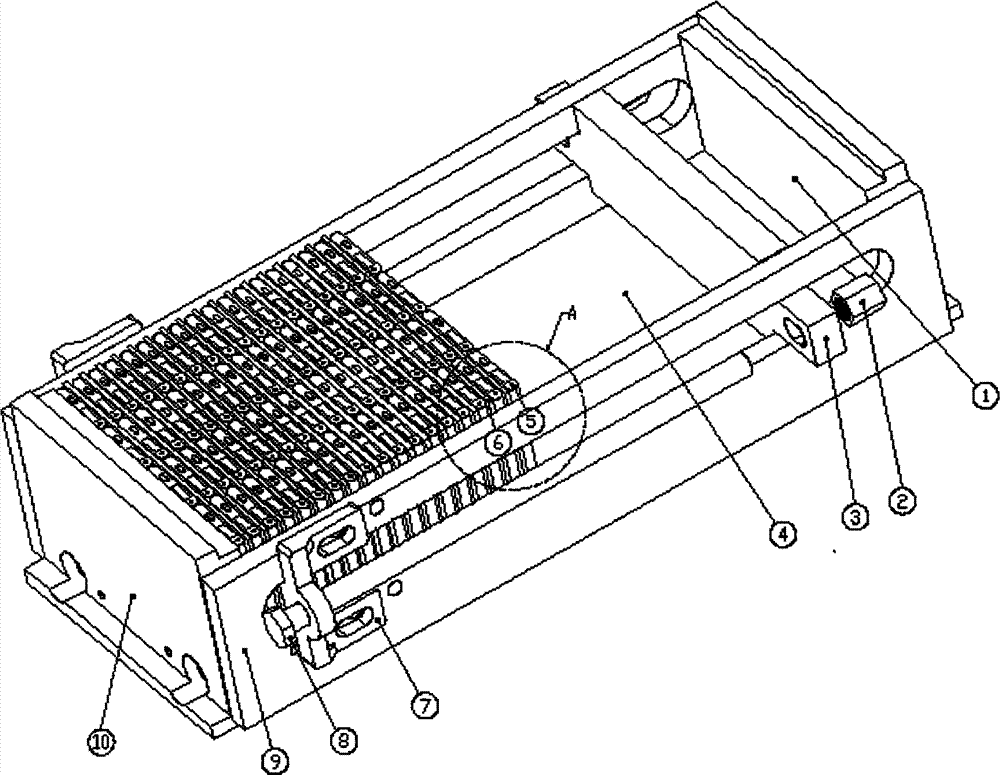

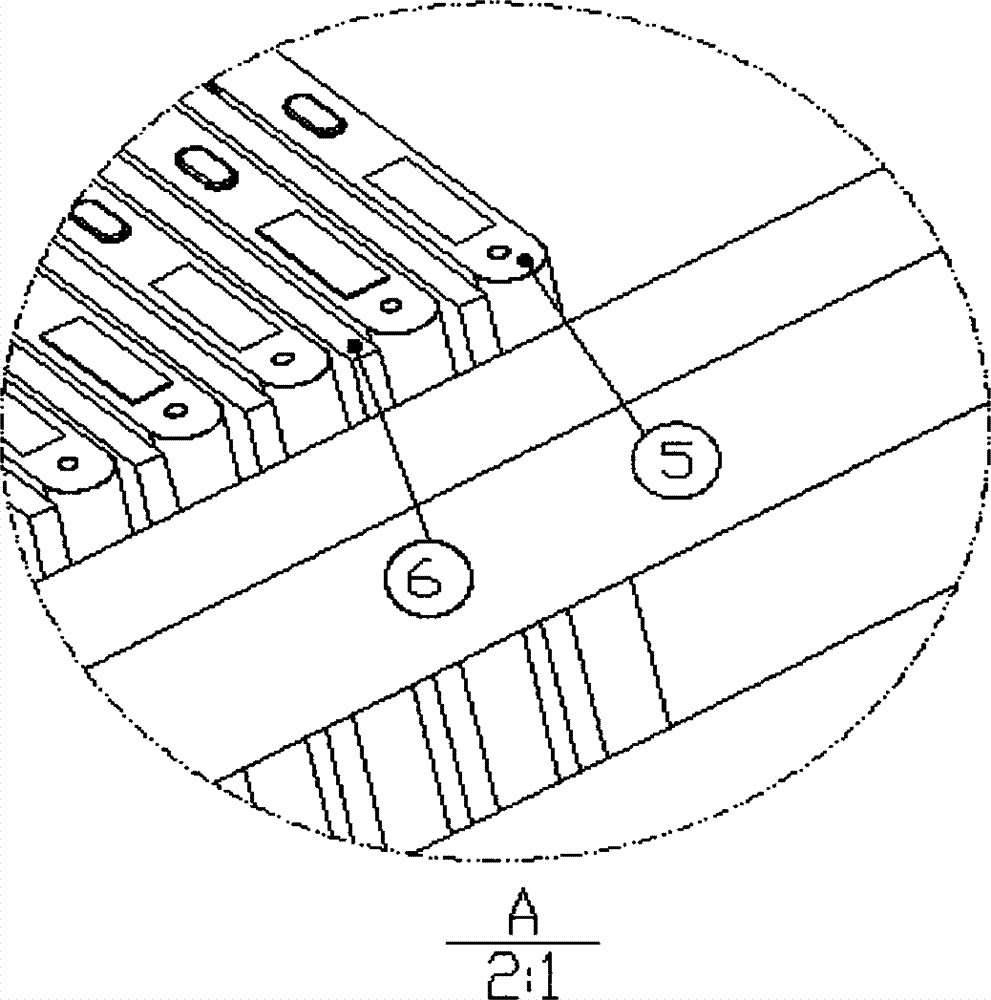

[0030] We use as figure 1 Fixture shown. The fixture includes a plurality of parallel battery separators 6, and the square lithium-ion battery 5 to be liquid-filled is discharged between the parallel separators 6, and the fixed plate 3 is moved to clamp the batteries. Pass the bolts 8 on the outside of the two side baffles through the screw holes of the bolt frame 7 and the fixing plate 3, and pre-fix them with the fixing nuts 2 respectively. Adjust the distance between the battery separators 6 to be 0.2 mm greater than the thickness of the battery to be filled, and then tighten the fixing nuts 2 . In this way, the jig with the battery to be filled can be put into the liquid injection tank for liquid injection.

[0031] The battery separator 6 and the fixed plate 3, whose area is greater than or equal to the larger size of the square lithium-ion ba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com