Small filament rubbing machine device and method for treating farmland waste through aeration fermentation house

A silk machine and small-scale technology, which is applied in the field of farmland waste treatment, can solve the problems of destroying nodules and waxy layers, and achieve the effect of increasing the flexibility of use, reducing the generation of leachate, and saving manpower and material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

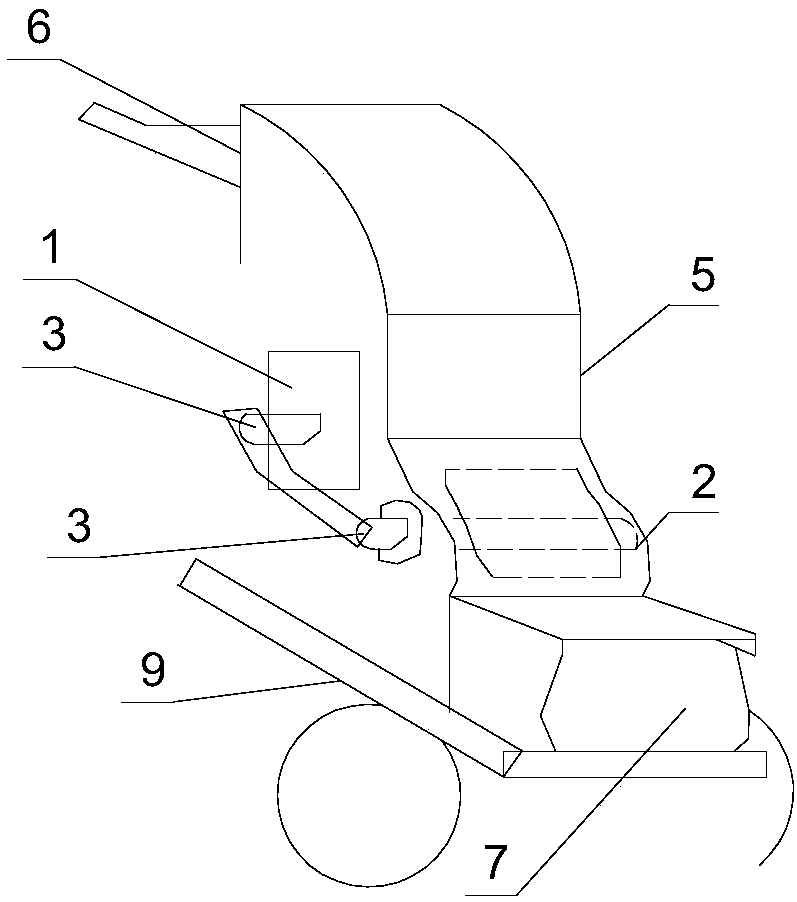

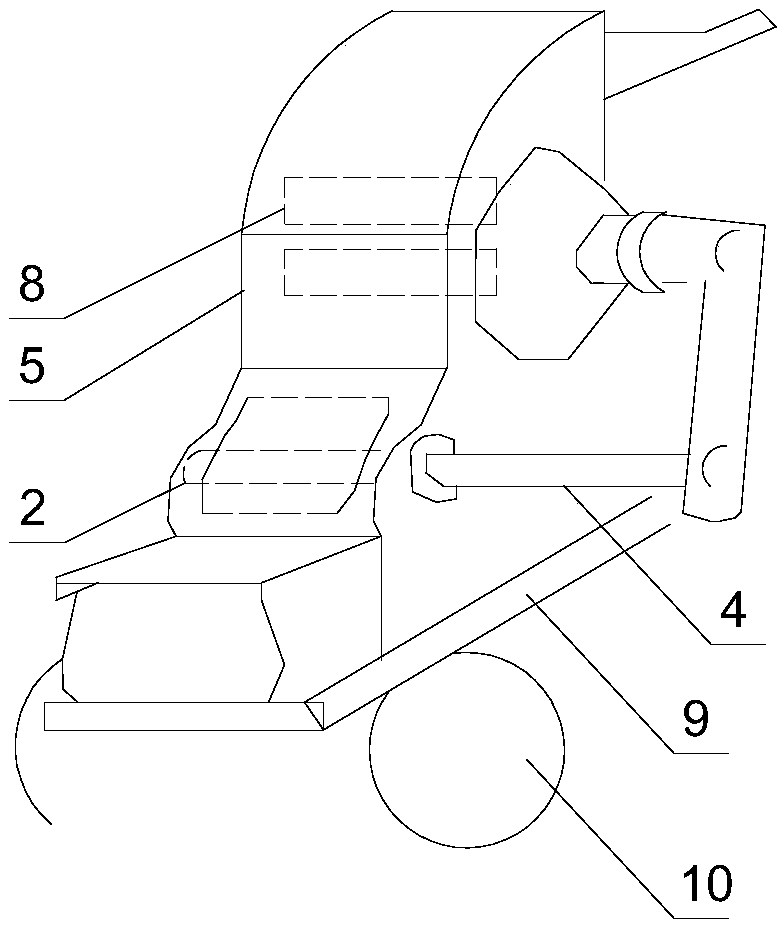

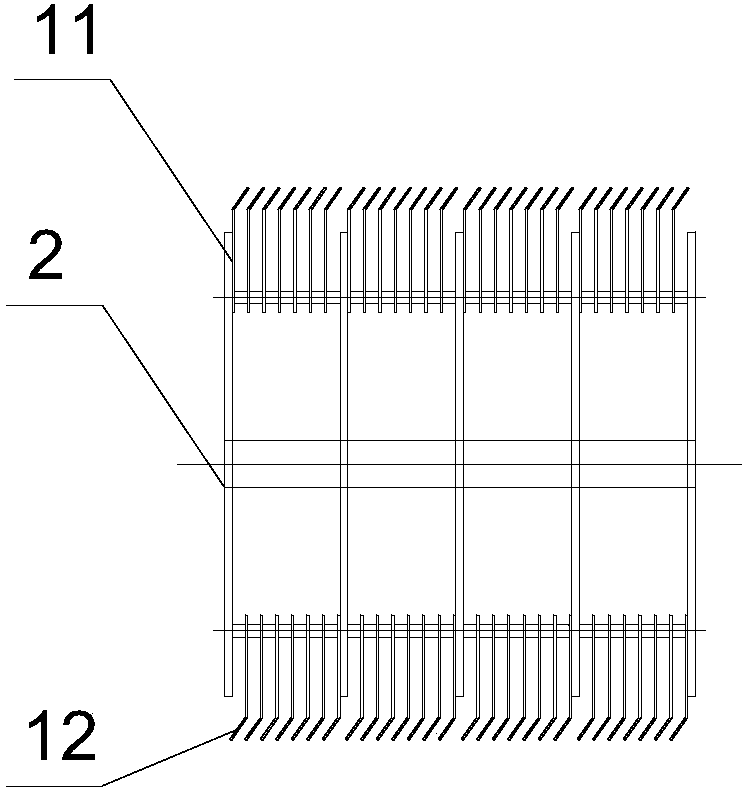

[0049] This embodiment provides a method for treating farmland waste with a small-scale kneading machine device and an aerated fermentation room. For details, see Figure 1-4 shown.

[0050] One end of the gasoline engine 1 and the kneading silk shaft 2 is provided with a pulley 3. First, adjust the transmission belt of the gasoline engine 1 and the kneading silk shaft 2 to a loose state, pull the start line to start the gasoline engine, and adjust the throttle to tighten the transmission belt of the gasoline engine. After idling for 1-2 minutes, after the rotating speed is stable, the material to be processed is manually put into the material inlet 6 at the top of the rubbing barrel 5, and the power of the gasoline engine is 7.6KW. The material inlet is provided with an automatic feeding device, and the automatic feeding device is a double-pressure roller device 8 arranged oppositely. The other end of the kneading silk shaft is provided with a transmission shaft 4, and the tr...

Embodiment 2

[0053] Other steps are the same as in Example 1, the fermentation period is 10 days, and the moisture content of the material is reduced to below 25% after fermentation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com