Charging system for cupola furnaces

A technology of feeding system and cupola, which is applied to furnaces, vertical furnaces, furnace components, etc., can solve the problems of large footprint, large width, and low utilization rate of the feeding machine, and achieves simple and reliable structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] (Embodiment 1, the charging system of the cupola)

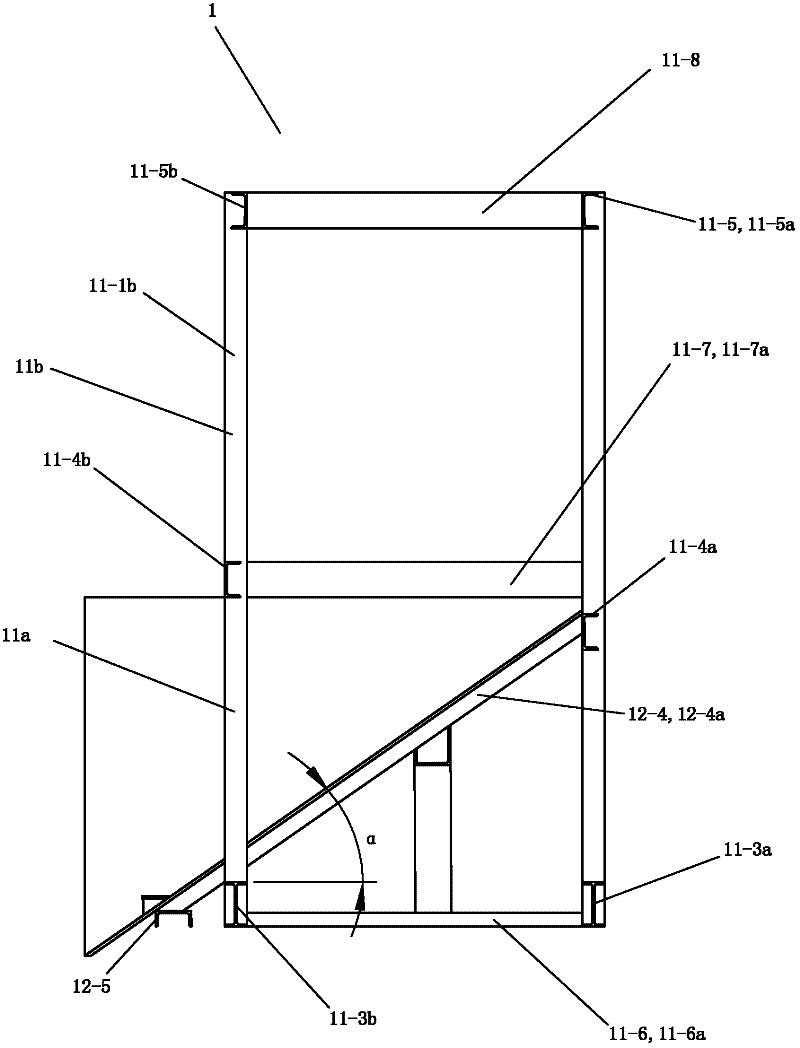

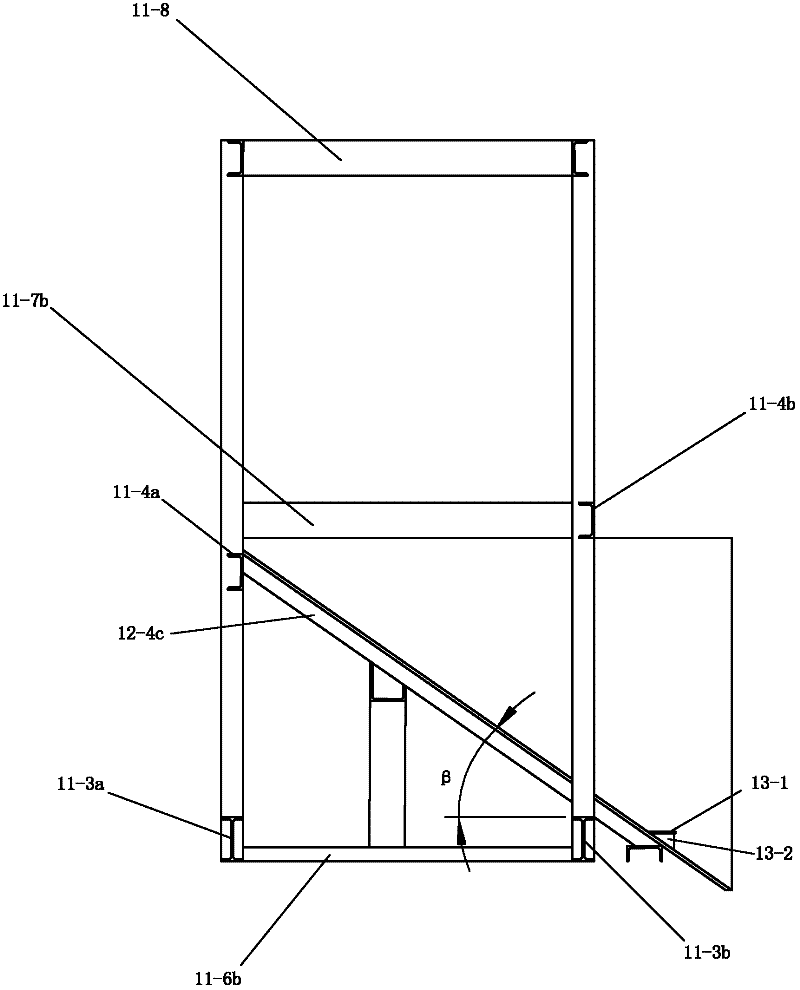

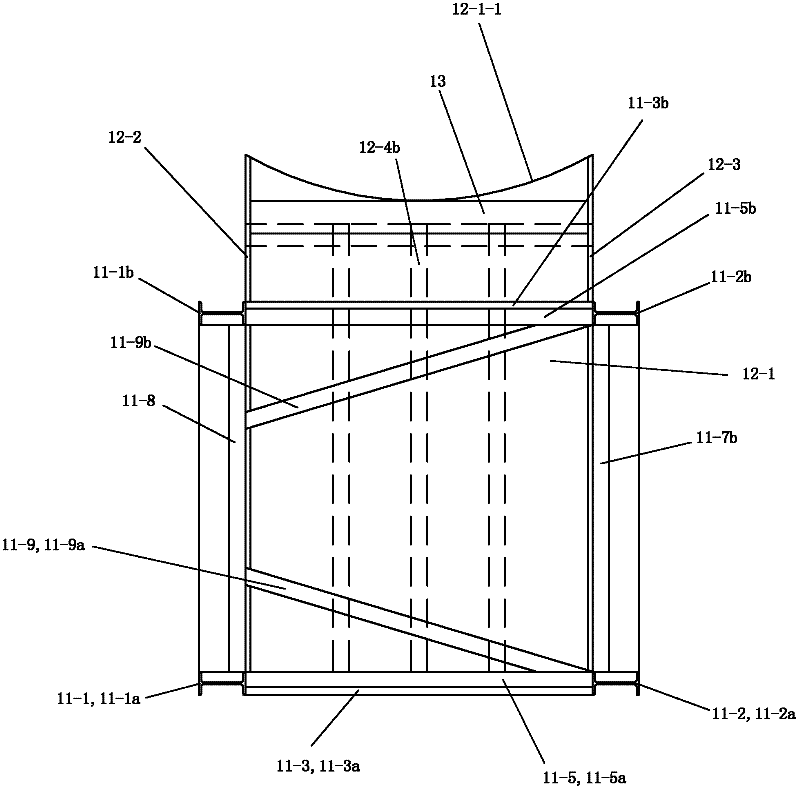

[0056] See figure 1 and Figure 6 , The feeding system of the cupola of the present invention includes a material guide device 1 and a feeding device 3 .

[0057] There are two material guides 1, the structures of the two material guides 1 are symmetrical, and the two material guides (1) are basically symmetrical with respect to a front-to-back vertical plane between them. The front side of the cupola. The two material guides 1 are divided into left side material guide 1a and right side material guide 1b according to their left and right positions.

[0058] Both material guiding devices 1 include a supporting structure, a material guiding structure 12 and a buffer device 13 . The support structure is a wedge-shaped support base or steel structure support frame made of cement and bricks (this embodiment is a support frame composed of straight steel components fixedly connected to each other in sequence, and the stra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com