Heat pump type method and equipment for drying gun powder

A heat pump type, gunpowder technology, applied in explosives, explosives processing equipment, offensive equipment, etc., can solve the problems of long drying time, high steam temperature, low efficiency, etc., achieve fast drying speed, high drying efficiency, and reduce cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

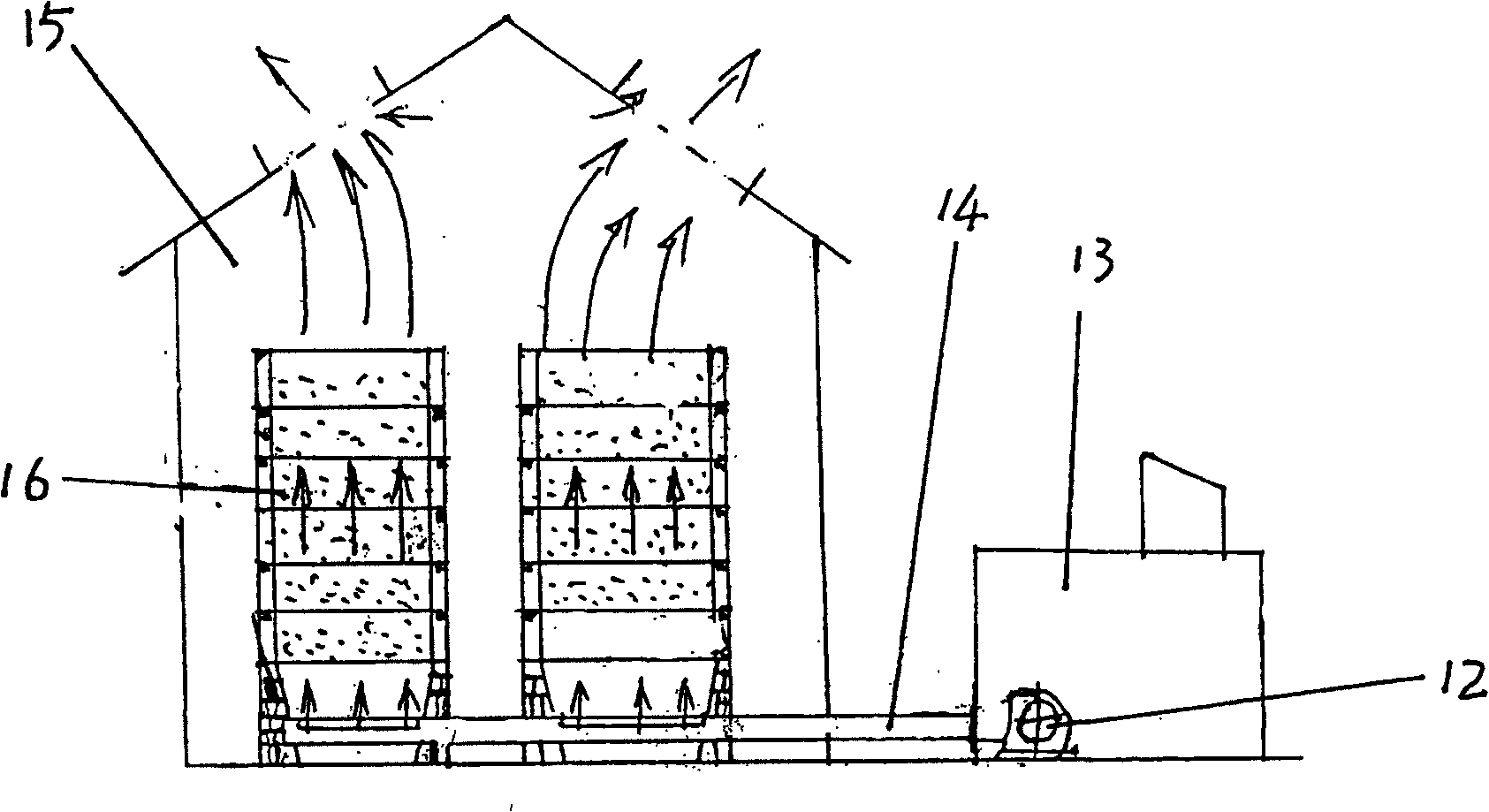

[0019] The present invention will be further described below in conjunction with accompanying drawing.

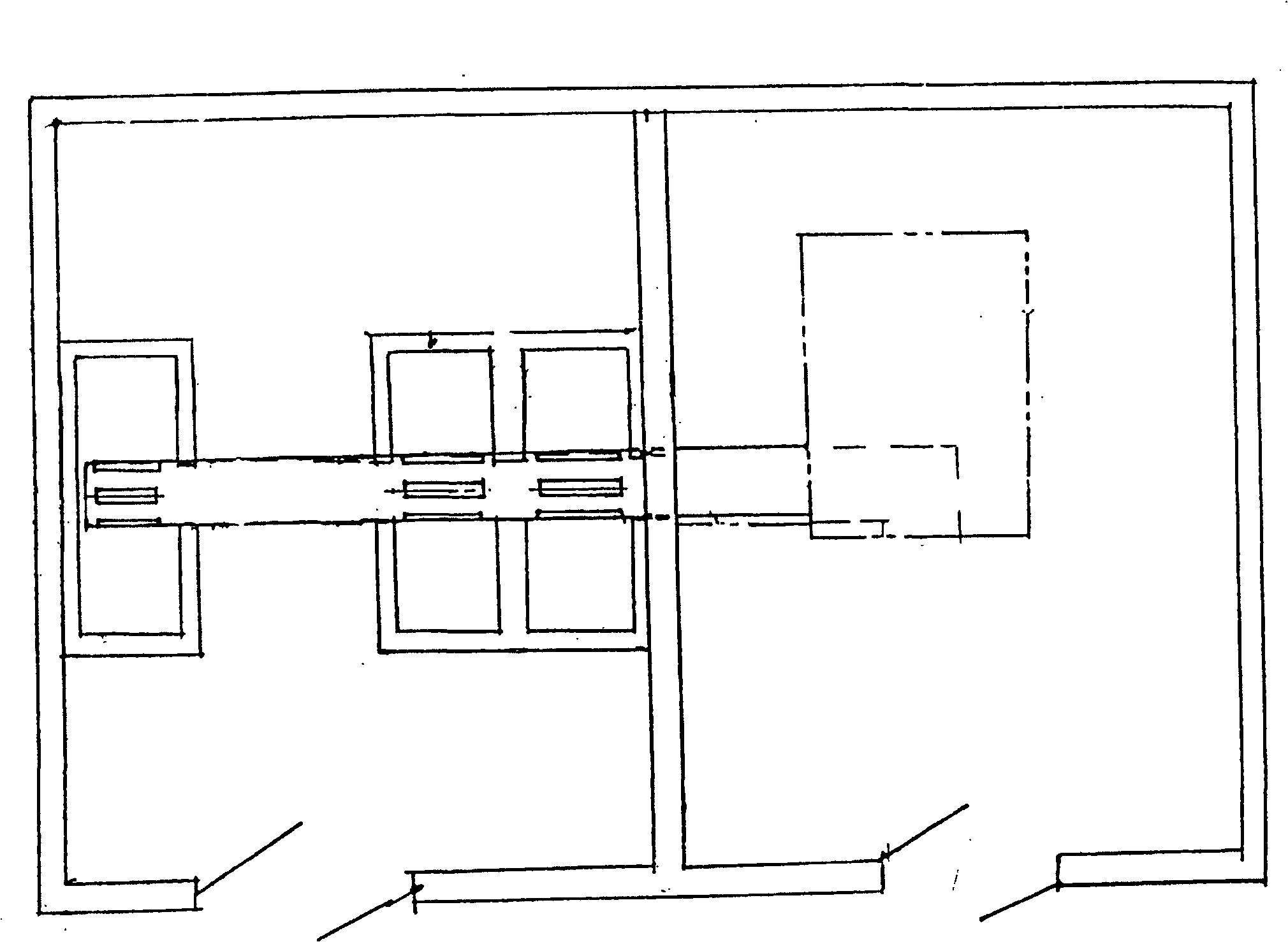

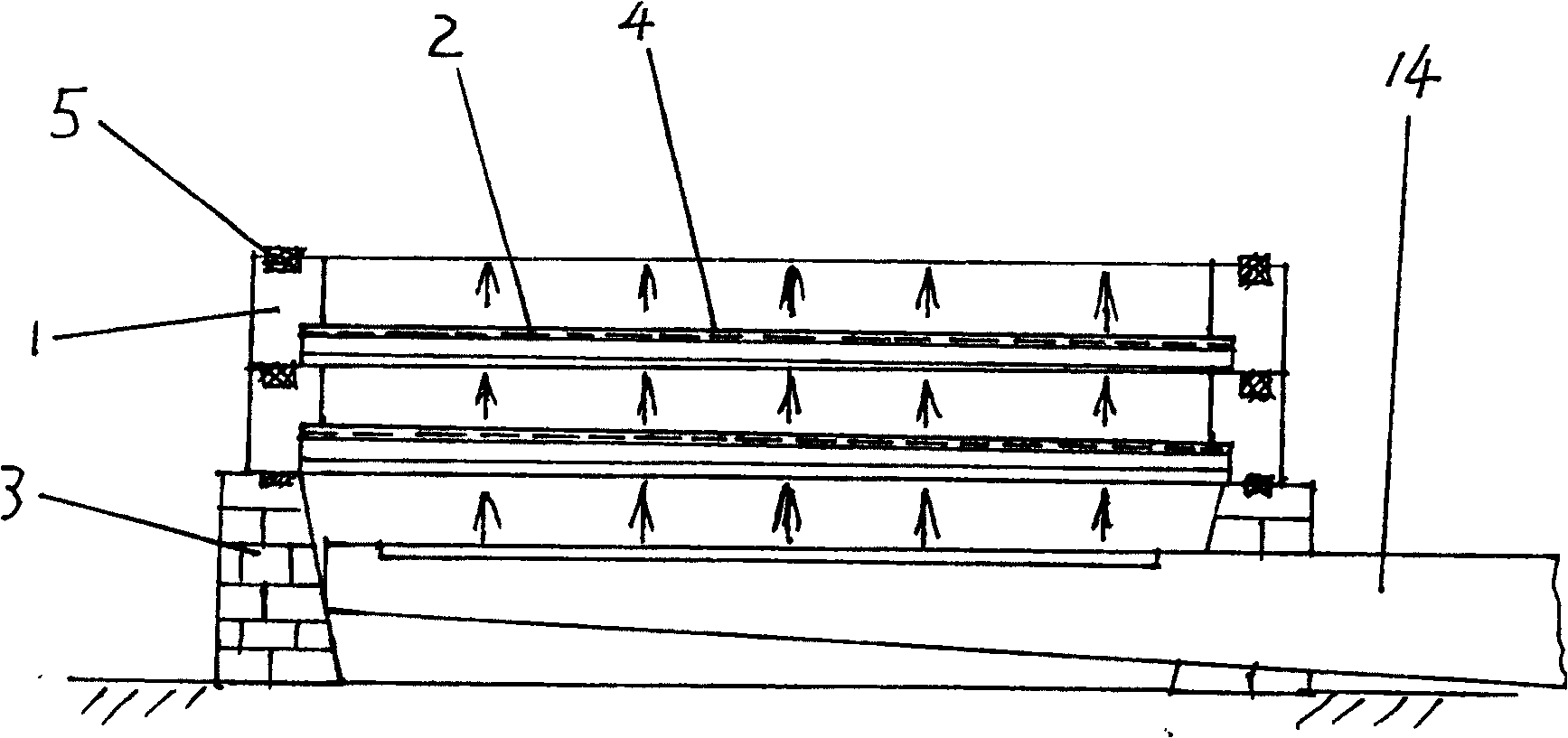

[0020] as attached figure 1 , attached figure 2 Shown, the present invention is made up of heat pump 13, centrifugal fan 12, air duct 14, drying room 15, drying cage 16, and heat pump is connected on the centrifugal fan, and centrifugal fan is assembled in the heat pump machine or outside the heat pump machine, and centrifugal fan outlet and One end of the air pipe is connected, and the other end of the air pipe is in the drying room. Area, the cross-sectional area of the air duct becomes smaller gradually, the drying cage is set on the air outlet of the air duct, there are more than one air outlets on the air duct, and a drying cage is set on each air outlet, and the drying cage is composed of a drying cage seat and Composed of drying grids, the drying grids are placed on the drying cage base, and the drying cage base is connected to the air duct. The drying grid is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com