Sealing device for preventing flue gas from overflowing when tamping coke oven is charged with coal

A technology for tamping coke ovens and sealing devices, which can be applied to doors/closures of coke ovens, charging devices, heating of coke ovens, etc. The effect of stable and reliable operation, not easy to tilt, and reliable and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

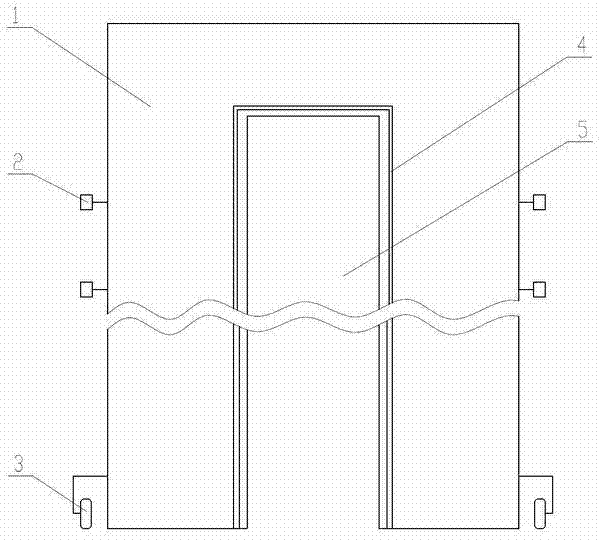

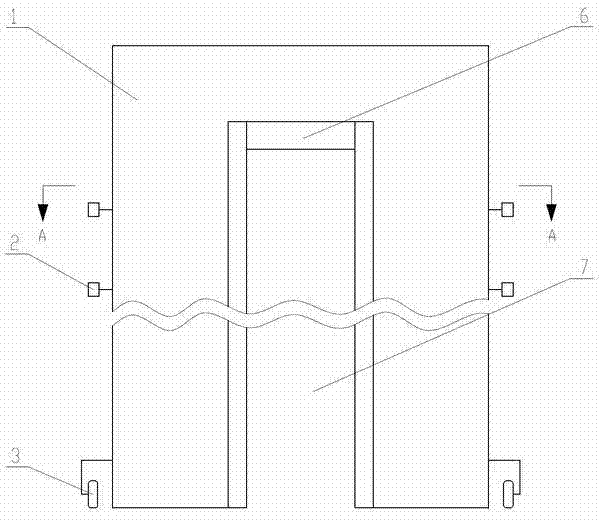

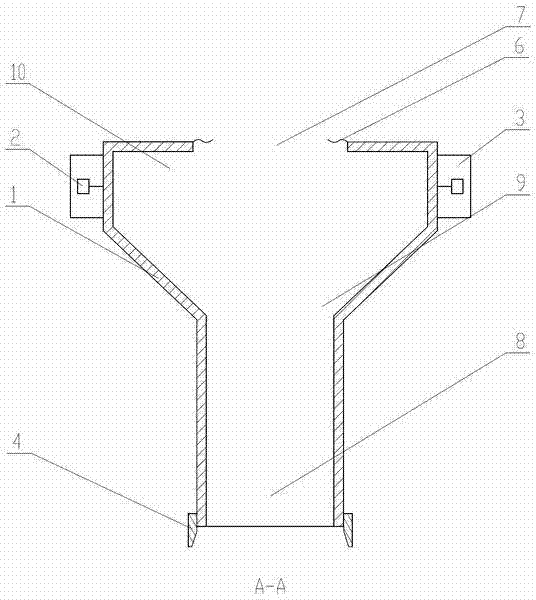

[0022] Depend on Figure 1 to Figure 3 It can be seen from the shown embodiment 1 that: the sealing device for preventing the flue gas from overflowing when the tamping coke oven is charged with coal includes a casing 1 with an opening on the bottom; the casing 1 is a flue gas buffer chamber; The front and rear end faces are respectively provided with a front door 5 and a back door 7, the front door 5 is compatible with the furnace door of the tamping coke oven, and a sealing knife edge 4 is respectively provided on both sides and the upper edge of the front door 5, and the The left and right edges and the upper edge of the rear door 7 are respectively provided with high-temperature-resistant soft sealing strips 6; the middle part of the outer sides of the left and right side walls of the smoke buffer chamber are respectively provided with guide rails on the coal loading car. Compatible guide wheels 2; anti-deformation rail holding wheels 3 are respectively provided at the bot...

Embodiment 2

[0031] Depend on Figure 4 The shown embodiment 2 shows that: different from embodiment 1, the smoke buffer chamber is composed of a front chamber 11 and a rear chamber 12; the cross-sectional shape of the front chamber 11 is rectangular, and the rear chamber The cross-sectional shape of the chamber 12 is a semicircle, and the radius of the semicircle is greater than the width of the front chamber 11; the height of the front chamber 11 and the rear chamber 12 are equal. The heights of the front chamber 11 and the rear chamber 12 can also be unequal, and the tops of the front chamber 11 and the rear chamber 12 can be gradually raised, so that the capacity of the smoke buffer chamber becomes larger, which is more conducive to storing the spilled gas. The flue gas in the flue gas buffer chamber.

[0032] The lines of the outer wall of the housing of the device can be straight lines or curved lines. It can be processed according to the actual situation. As long as the internal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com