Damping ring for multi-section aluminum-casting rotor and processing method of aluminum-casting rotor

A technology of cast aluminum rotor and damping ring, which is applied in the manufacture of stator/rotor body, magnetic circuit rotating parts, magnetic circuit shape/style/structure, etc. and other problems, to achieve the effect of solving overflow and air bubbles, uniform force, and improving the quality of iron core lamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

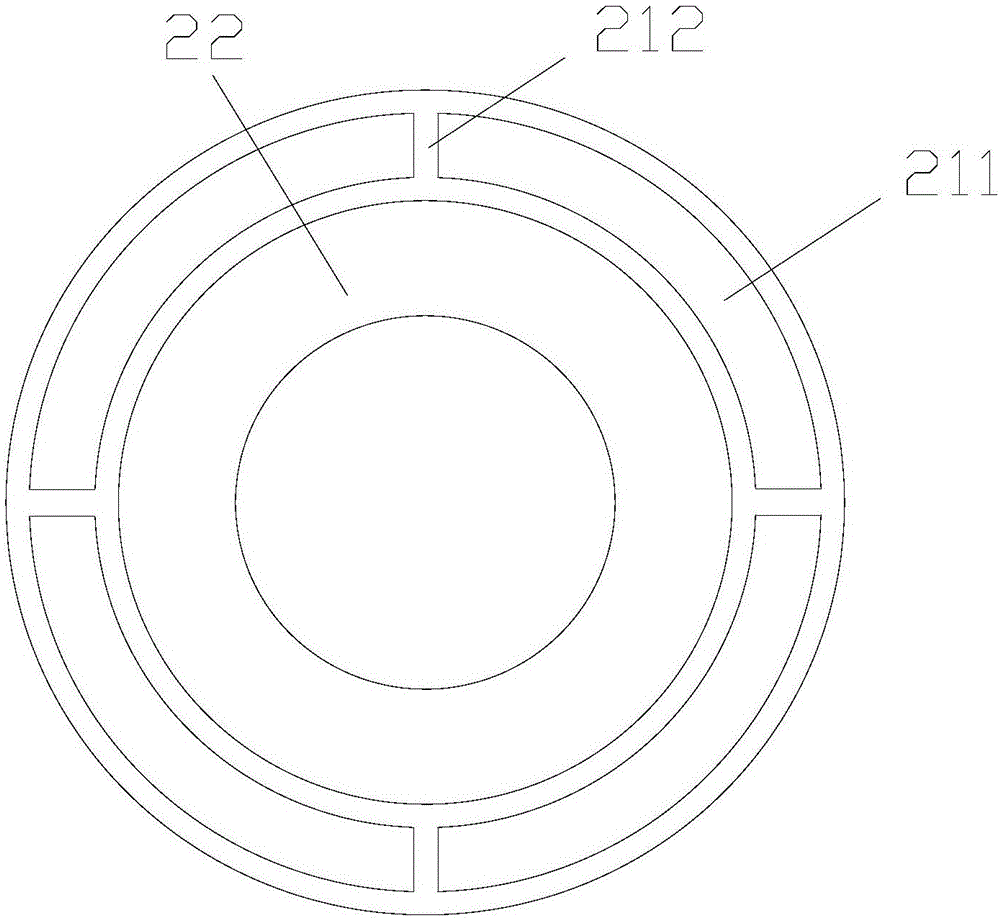

[0024] Such as figure 1 As shown, a damping ring for a multi-segment cast aluminum rotor, the damping ring includes an outer aluminum ring and an inner silicon steel ring 22 . The aluminum ring is provided with cast aluminum through-slots 211 , and several cast-aluminum through-slots 211 are equidistantly distributed in a ring structure; the area between two adjacent cast-aluminum through-slots forms grooved ribs 212 . The plurality of cast aluminum through-slots 211 form the same number of slotted ribs 212 as the number of cast aluminum through-slots 211, and the number of slotted ribs 212 is a divisor of the number of rotor slots.

[0025] Preferably, the cast aluminum channel 211 has a fan-shaped structure, and several cast aluminum channels are equidistantly distributed to form an annular structure concentric with the center of the damping ring.

[0026] The outer diameter of the damping ring is consistent with the outer diameter of the rotor. The width of the grooved rib...

Embodiment 2

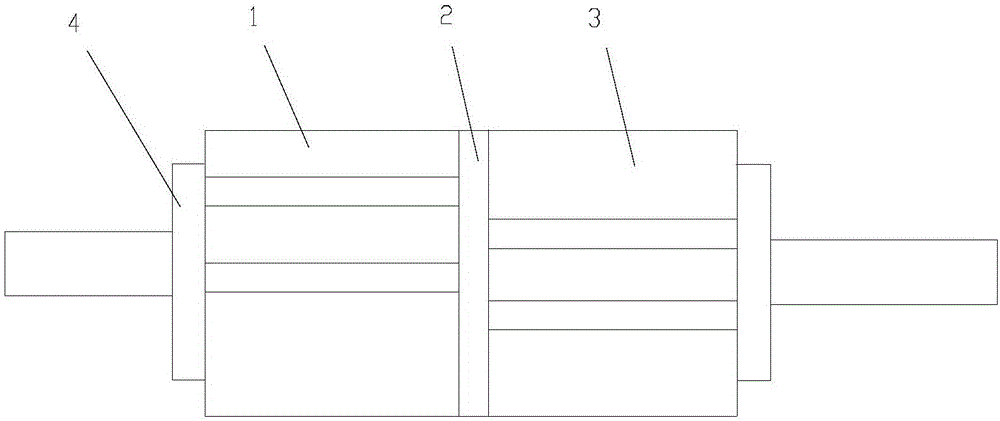

[0028] Such as figure 2 As shown, this embodiment includes two sections of the first rotor core 1 and the second rotor core 3 of equal length. When stacking, the first rotor core 1 is stacked first, and then the damping ring 2 and the second rotor core 3 are stacked. Go up to form a whole to ensure that the grooved ribs and the iron core groove are misaligned. When casting aluminum, the aluminum water is injected from the end of the first rotor core 1, and the aluminum water enters through the fan-shaped cast aluminum channel of the concentric aluminum ring of the damping ring 2 when passing through the interface between the first rotor core 1 and the second rotor core 3 Rotor core 3. After the casting is completed, aluminum water fills the fan-shaped cast aluminum channel of the concentric aluminum ring to form a complete aluminum ring, connects the guide bars of each section of the rotor into a whole, and forms a cast aluminum end at the end of the whole Ring 4, the castin...

Embodiment 3

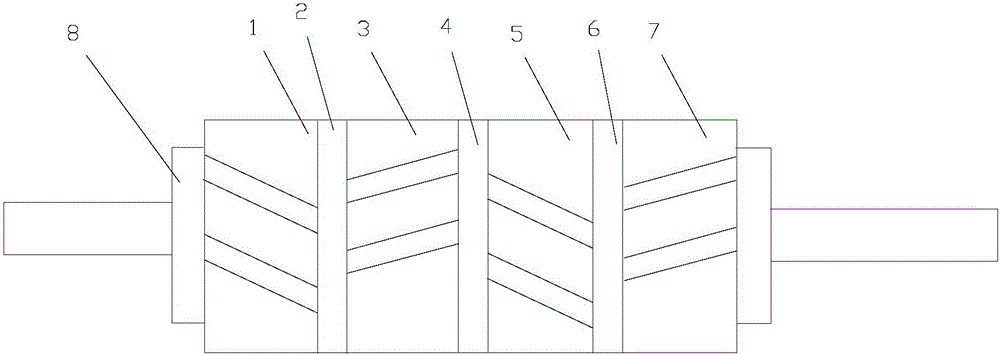

[0039] Such as image 3 As shown, this embodiment includes four sections of the same length as the first rotor core 1, the second rotor core 3, the third rotor core 5, the fourth rotor core 7, the first damping ring 2, the second damping ring 4, the third Damping ring 6, when stacking, first stack the first rotor core 1 of the rotor, then stack the first damping ring 2 and the second rotor core 3, and then stack the second damping ring 4 and the third rotor core 5 Go up, and finally the third damping ring 6 and the fourth rotor core 7 are laminated to form a whole, so as to ensure that the grooved ribs and the iron core grooves are misaligned. When casting aluminum, the aluminum water is injected from the end of the first rotor core 1, and when the aluminum water passes through the interface between the first rotor core 1 and the second rotor core 3, it passes through the fan-shaped cast aluminum channel of the first damping ring 2 concentric aluminum ring Enter the second ro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com