Geopolymer-based rice straw fiber board and preparation method thereof

A technology of geopolymer and rice straw, applied in the field of geopolymer-based plant fiberboard and geopolymer-based rice straw fiberboard, can solve the problems of complex raw materials and processes, achieve small equipment wear, low material moisture content, and solve the problem of slurry spillover effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

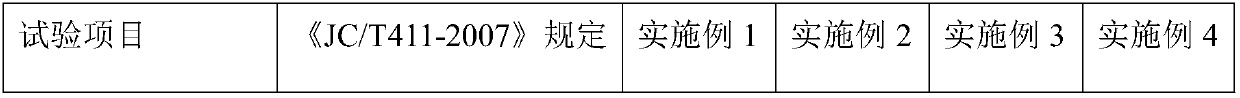

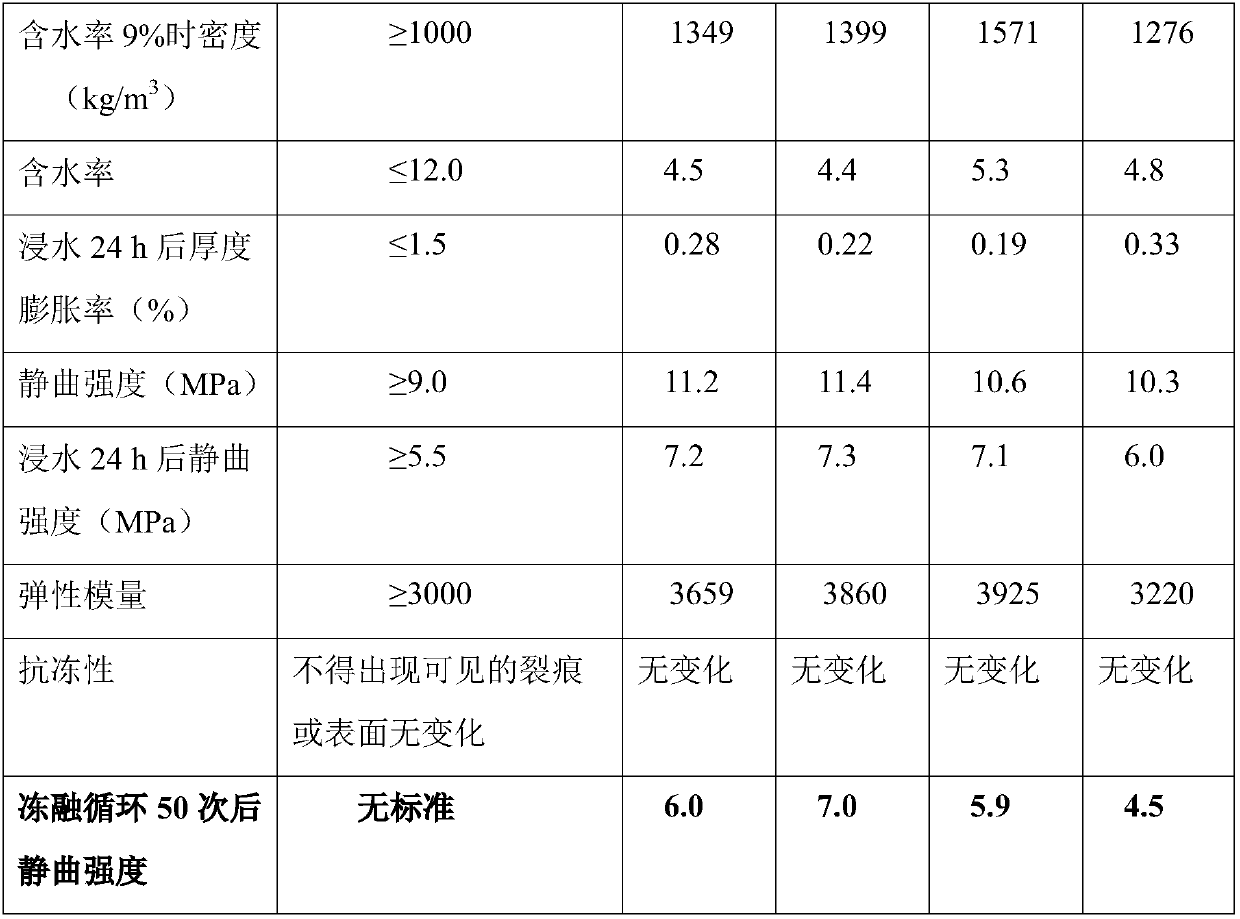

Examples

Embodiment 1

[0032] Taking by weighing modulus is 1.5, and solid content is 57 kilograms of liquid sodium water glass of 48%, and fineness is 33 kilograms of metakaolin of 200 orders, and particle diameter is 10~20 orders, and water content is 10 kilograms of rice straw fibers ( dry basis); add liquid sodium water glass to the metakaolin, fully stir during the adding process, and stir until there is no agglomerated metakaolin in the mixture to obtain a geopolymer-based slurry; add rice straw fiber to the slurry , fully stirred and mixed to obtain a mixed slurry of geopolymer and rice straw fiber; the mixed slurry was moved to a fiberboard mold, extruded at 1.5MPa and 60°C, demoulded after 2 hours, and then placed in a natural Under the condition of conservation for 10 days, that is.

[0033] Among them, liquid sodium water glass is obtained by adding a certain amount of sodium hydroxide to commercially available industrial liquid sodium water glass with a modulus of 3.1 and a solid content...

Embodiment 2

[0035] Taking by weighing modulus is 1.6, and solid content is 60 kilograms of liquid sodium water glass of 47.0%, and fineness is 30 kilograms of metakaolin of 400 orders, and particle diameter is 20~40 orders, and water content is 10 kilograms of rice straw fibers ( dry basis); add liquid sodium water glass to the metakaolin, fully stir during the adding process, and stir until there is no agglomerated metakaolin in the mixture to obtain a geopolymer-based slurry; add rice straw fiber to the slurry , fully stirred and mixed to obtain a mixed slurry of geopolymer and rice straw fiber; the mixed slurry was moved to a fiberboard mold, extruded at 1.5MPa and 60°C, demoulded after 2 hours, and then placed in a natural Under the condition of conservation for 9 days, that is.

[0036] Among them, liquid sodium water glass is obtained by adding a certain amount of sodium hydroxide to commercially available industrial liquid sodium water glass with a modulus of 3.2 and a solid conten...

Embodiment 3

[0038] Taking by weighing modulus is 1.7, and solid content is 57 kilograms of liquid sodium water glass of 46.5%, and fineness is 35 kilograms of metakaolin of 600 orders, and particle diameter is 20~40 orders, and water content is 8 kilograms of rice straw fiber of 18% ( dry basis); add liquid sodium water glass to the metakaolin, fully stir during the adding process, and stir until there is no agglomerated metakaolin in the mixture to obtain a geopolymer-based slurry; add rice straw fiber to the slurry , fully stirred and mixed to obtain a mixed slurry of geopolymer and rice straw fiber; the mixed slurry was moved to a fiberboard mold, extruded at 1.5MPa and 60°C, demoulded after 2 hours, and then placed in a natural Under the condition of conservation for 8 days, that is.

[0039] Among them, the liquid sodium water glass is obtained by adding a certain amount of sodium hydroxide to commercially available industrial liquid sodium water glass with a modulus of 3.3 and a sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com